Micro Perforating Machines by Spark Machinery

Overview of our Micro Perforating Machines

Spark Machinery offers a comprehensive range of needle and laser micro-perforating machines designed for precision and efficiency across diverse materials and industries. These advanced solutions ensure optimal permeability and functionality for various applications, from packaging and textiles to automotive and medical products.

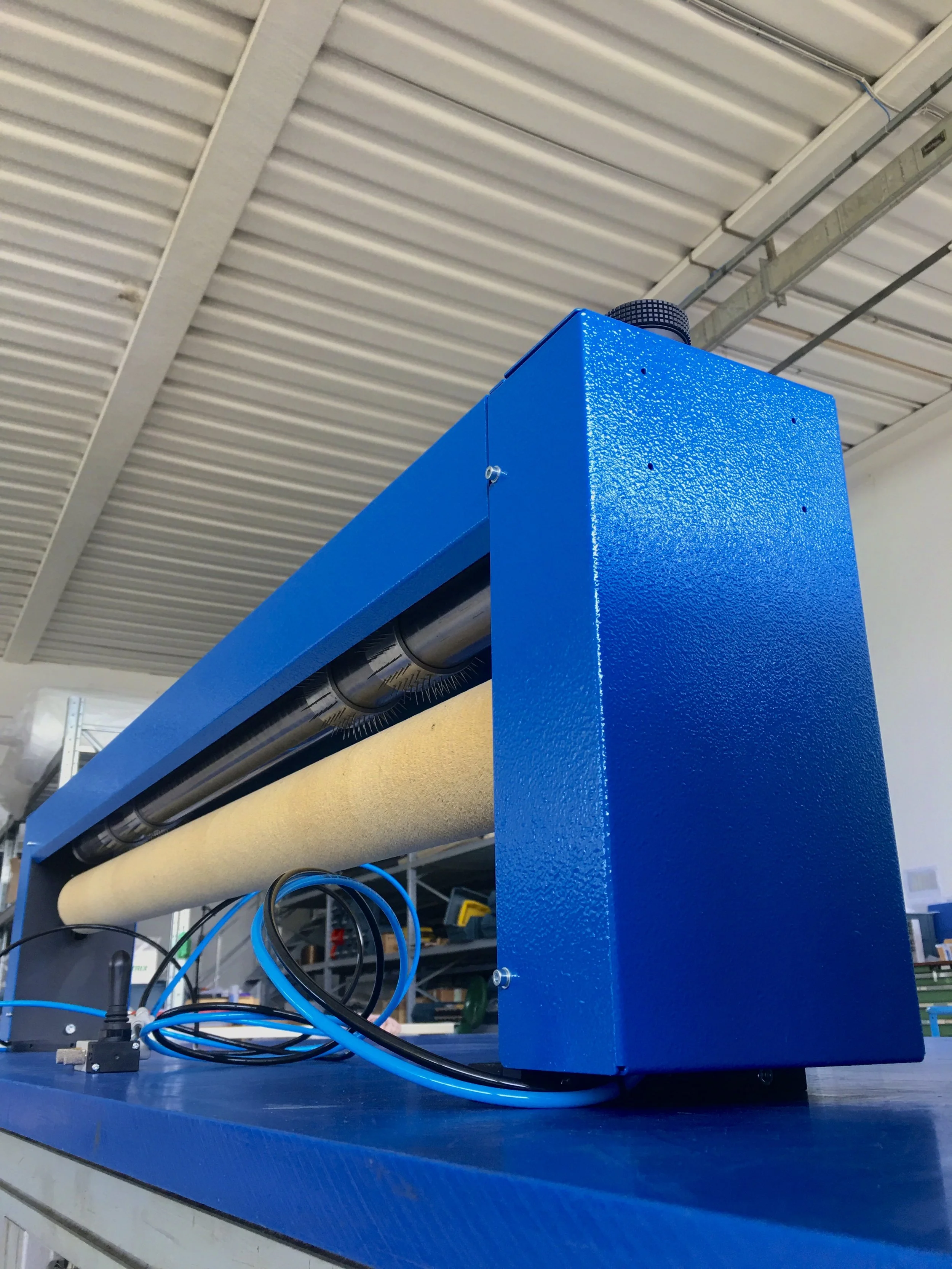

Hot Needle Microperforators

HN Series: Ideal for applications requiring precise, clean holes, the HN series utilizes heated needles to melt material, creating holes from 200µm to 2mm. This technology is highly versatile, featuring interchangeable cylinders for customized patterns.

Model HN100 HOT MICRO PERFORATION system for holes from 200µ to 2mm with motorized needle roller of Ø100mm

Useful range : 600-1800

Hole Ø: Min. 200µm / Ø Max. 2mm

Needle roller Ø: 100mm

Max Speed: 150 mt per minute

Temperature Max: 300° C

Movement : Motorized

Cold Needle Microperforators

CN Series: A cost-effective and efficient solution, the CN series perforates thin materials without heat, preserving material characteristics. These machines create holes from 80µm to 1.8mm.

Model CN-60 Cold MICRO PERFORATION system for holes from 80µ to 1mm with motorized needle roller Ø60mm

Hole Ø: Min. 80µ / Ø Max. 1mm

Needle roller Ø: 60mm

Max Speed: 300 mt per minute

Movement: by dragging of the film

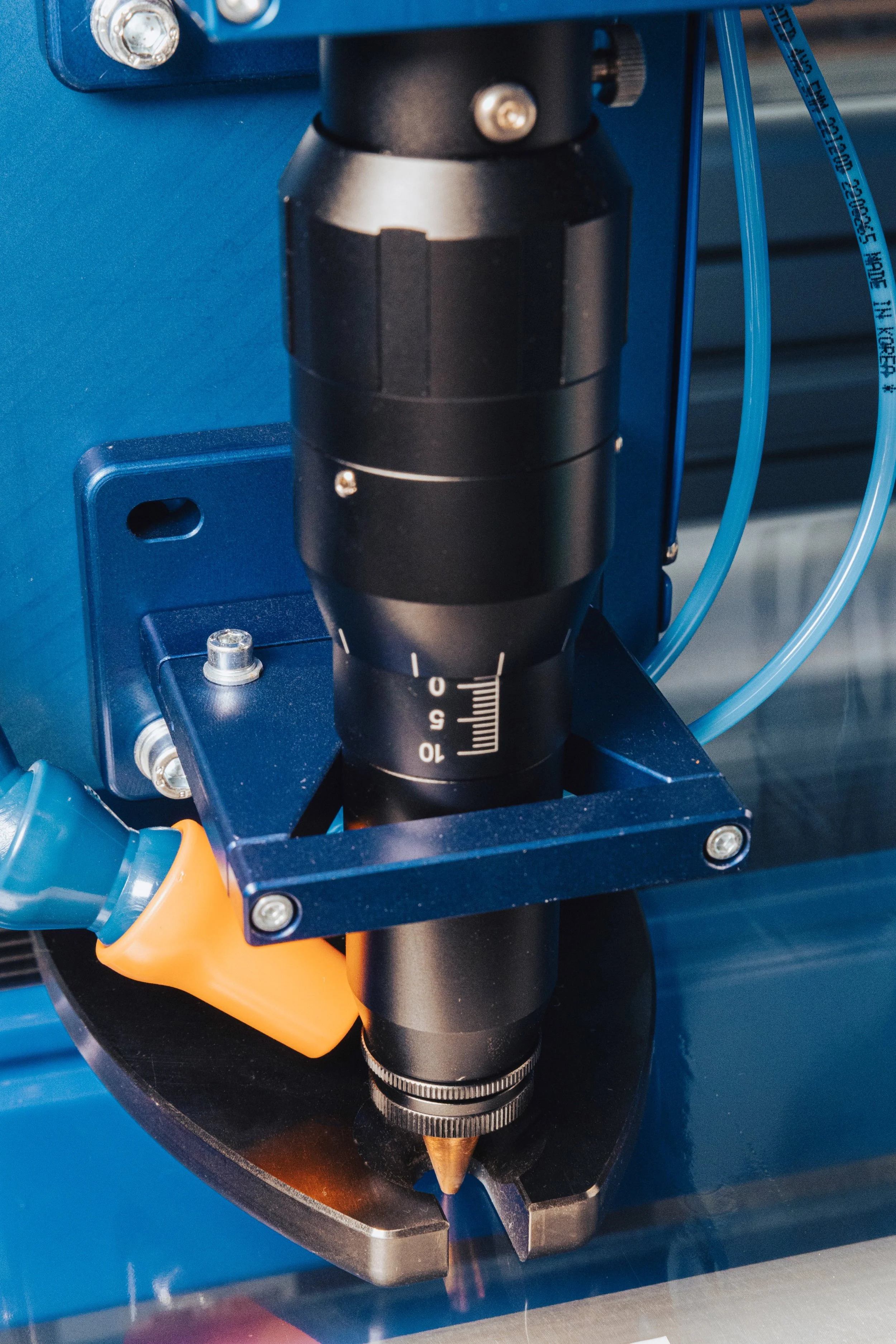

Laser Microperforators

LO Series: This advanced, non-contact solution precisely creates micro-holes using focused laser beams. It ablates material for superior hole quality and maintains material integrity, without distortion. Ideal for delicate films and complex patterns, these machines typically generate holes from 40µm to 200µm, offering unmatched control and versatility.

Model LO-S40 Scanning LASER MICRO perforation system, for 70µm to 200µm holes and pre-cuts

Operation: Scanning laser

Hole Ø: Min. Ø70µm - Max. Ø200µm

No. of laser sources: Min. 1 - Max 6

Max Speed: 380 mt per minute

Cooling system: Liquid

Optional: Camera

What is Micro Perforation?

Micro-perforation is the process of creating a multitude of extremely small, precisely engineered holes in a material. These microscopic holes, often measured in micrometers (µm), are generally imperceptible to the naked eye but collectively alter the material's properties.

How it Works:

The primary methods for achieving micro-perforation include:

Mechanical Needling: This method uses rollers or flat beds fitted with arrays of tiny, sharp needles.

Cold Perforation: Needles pierce the material at ambient temperature, producing clean, precise holes. This is ideal for materials sensitive to heat.

Hot Perforation: Heated needles melt through the material, often creating a slightly raised rim around the hole. This can result in a more defined opening and is suited for specific material types.

Laser Perforation: A highly focused laser beam precisely vaporizes minuscule sections of the material, creating very accurate holes with minimal material disruption. This technique offers exceptional control over hole size and intricate patterns.

The exact pattern, density, and size of these micro-perforations are meticulously controlled to achieve desired functional outcomes.

Relevance for Packaging:

Micro-perforation is vital in modern packaging, boosting product preservation, safety, and consumer convenience. Key applications include:

Breathability & Controlled Atmosphere: Enables precise gas exchange (e.g., oxygen, CO2) to extend shelf life for fresh produce and baked goods by preventing moisture and regulating respiration.

Anti-Fog Properties: Prevents condensation in clear packaging, maintaining product visibility for refrigerated items.

Easy Opening: Creates weak points for convenient, clean tearing.

Ventilation & Pressure Equalization: Allows controlled venting for off-gassing products (e.g., hot food), preventing package deformation.

Essentially, micro-perforation transforms inert packaging into functional components that actively enhance product quality and longevity.

Different types of Micro Perforation Machines

Cold needle micro perforation

Cold perforation is a mechanical process forming tiny holes in materials without heat. Sharp needles on a roller or flat bed physically pierce the material against a counter roller, with penetration depth precisely controlled. Unlike hot perforation, it doesn't melt, producing clean-pierced holes with slight burrs.

Predominantly used for:

Heat-Sensitive Materials: Prevents degradation in plastics, paper, or non-wovens.

Cost & Speed Efficiency: High-volume, fast process for wide webs.

Specific Hole Needs: Creates "one-way valve" effects or breathability without material alteration.

Common applications include fresh produce packaging, paper tear lines, and non-woven hygiene fabrics, due to versatility and easy integration into production lines.

Hot needle micro perforation

Hot perforation uses heated needles to create holes in materials. Technically, heated needles on a rotating cylinder melt through the substrate, forming perfectly round holes with heat-sealed, welded edges. This fusion prevents tearing and ensures holes remain open.

It's predominantly used for:

Thermoplastic Films: Such as polyolefins (LDPE, PP) for clean, consistent holes.

Permanent Openings: Heat-sealed edges prevent re-closing, critical for consistent gas exchange.

Food Packaging: Extending shelf life of produce, baked goods, and ovenable films by controlling moisture/gas and preventing "ballooning."

Enhanced Strength: The molten ring strengthens the hole's integrity.

Laser micro perforation

Laser perforation is a non-contact process using a focused laser beam to create precise holes. The laser's energy ablates or melts material, forming clean, burr-free holes with minimal heat effect. Precise control over laser parameters ensures exceptional accuracy in hole size, shape, and pattern.

Widely used when:

High Precision & Small Holes: Ideal for micro-perforations (e.g., <50µm) unmatched by mechanical methods.

Non-Contact Processing: Prevents material deformation or contamination.

Complex Patterns & Flexibility: Digital control allows rapid design changes.

Delicate/Abrasive Materials: Works on films, foils, paper, composites, and more.

Modified Atmosphere Packaging (MAP): Controls gas exchange for extended food shelf life.

Easy-Open Features & Aesthetics: Creates precise score lines and unique designs.

Technical specifications of our Micro Perforators

| Parameter | Hot Needle Perforators (HN Series) |

|---|---|

| Perforation Speed (material/configuration dependent) | Up to ~200 m/min |

| Hole Sizes | Ø 100µm to Ø 2mm (some models to 2.8mm) |

| Supported Materials | Thermoplastic films (PE, PP, BOPP, PET), non-wovens, textiles, automotive materials |

| Patterns | Defined by interchangeable cylinders; customizable for tracks or full surface |

| Precision | High precision for clean, precise holes; limited by needle dimensions |

| Repeatability Metrics | Good consistency due to mechanical nature, subject to needle wear |

| Parameter | Cold Needle Perforators (CN Series) |

|---|---|

| Perforation Speed (material/configuration dependent) | Up to ~400 m/min |

| Hole Sizes | Ø 50µm to Ø 1.8mm |

| Supported Materials | PE, LDPE, HDPE, laminates, food-grade PVC, aluminum, paper, wood, non-wovens |

| Patterns | Defined by interchangeable cylinders; customizable for tracks or full surface |

| Precision | Precise and homogeneous perforations; generally lower than laser for very small holes |

| Repeatability Metrics | Good consistency; robust for high drilling densities; subject to needle wear |

| Parameter | Laser Perforators (LO Series) |

|---|---|

| Perforation Speed (material/configuration dependent) | Up to ~380 m/min (LO-S40 model) |

| Hole Sizes | Min. Ø 40µm |

| Supported Materials | PE, LDPE, HDPE, PP, BOPP, CPP, PLA, non-wovens, laminates, food-grade PVC, foils |

| Patterns | Highly flexible, digitally controlled; micro-holes, pre-cuts, scoring, complex shapes, logos |

| Precision | Unparalleled precision (software-controlled, non-contact); extremely high accuracy in hole size and placement |

| Repeatability Metrics | Unparalleled repeatability; no tool wear; precise control of hole properties for consistent performance |

Key benefits and advantages of Micro Perforation Technology

Micro-perforation provides significant technical advantages in material processing and packaging:

Optimized Gas Permeation: Precisely engineered apertures facilitate controlled gaseous exchange (O2, CO2, H2O vapor). This enables modified atmosphere packaging (MAP), regulating respiration rates and mitigating moisture condensation, crucial for extending perishable product viability.

Elevated Process Throughput: Integration of hot needle, cold needle, or laser perforation systems into continuous-feed production lines allows for high-velocity in-line processing, minimizing bottlenecks and maximizing units per hour.

Reduced Material Loss & Operational Expenditure: Precise control over perforation parameters minimizes material stress and defect rates. Concurrently, extended product shelf-life directly diminishes spoilage-related waste and associated logistics costs.

Superior Product Integrity & Extended Viability: Controlled atmospheric environments inhibit microbial growth and enzymatic degradation, maintaining optimal organoleptic properties. This preserves product freshness, texture, and nutritional value, significantly extending market appeal and shelf-life.

Why choose Spark Machinery for Micro Perforators?

Spark Machinery stands out through its unwavering commitment to Quality, Reliability, and Performance. Leveraging extensive experience, they deliver robust micro and macro perforating machines engineered for precision and efficiency across diverse industries.

A core USP is their customer-centric design approach, crafting tailored solutions that meet specific production demands. This bespoke engineering ensures optimal integration and functionality for each client.

Furthermore, Spark Machinery provides comprehensive support before, during, and after purchase and installation, including 24/7 after-sales service and remote assistance. This dedication extends to continuous innovation and rigorous quality control, solidifying their reputation as a trusted partner delivering not just machinery, but complete, high-performance solutions.

Applications of Micro Perforators

Micro-perforators are pivotal across diverse industries, optimizing material functionality:

Food Packaging 🍎: In fresh produce and vacuum packs, micro-perforations precisely control gas exchange (O2, CO2) via Modified Atmosphere Packaging (MAP). This regulates respiration rates, inhibits microbial growth, and prevents condensation, significantly extending shelf-life and maintaining product integrity.

Medical Packaging ⚕️: Essential for sterile barrier systems, micro-perforations enable controlled sterilization gas penetration while maintaining microbial barrier properties. This ensures product safety and compliance with stringent regulatory standards.

Automotive Sector 🚗: Applied to ventilation films and seating materials, micro-perforations enhance breathability and comfort by facilitating air circulation and moisture dissipation, improving cabin climate control and material performance.

Textiles 👕: Micro-perforated fabrics offer enhanced breathability, moisture wicking, and comfort for sportswear, technical apparel, and footwear, improving thermal regulation and user experience.

Get expert advice for your Micro Perforation Needs

Choosing the ideal micro-perforating machine can be a complex decision, given the diverse technologies and material considerations involved. To ensure you select the perfect solution for your specific needs, we invite you to a free, no-obligation consultation with our experts. Benefit from personalized insights into how the right hot, cold, or laser perforation technology can optimize your production, enhance product quality, and drive efficiency, ensuring a smart investment tailored to your success.

PERSONAL CONTACT PERSON

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

FEDERICA CANTAGALLI

Commercial Export Office

+39 3420324381

f.cantagalli@sparkmachinery.com