Packaging Fibrillation Components for Industrial Material Processing

What Is Packaging Fibrillation?

Packaging fibrillation is an industrial process that modifies the internal and surface structure of polymer-based materials, such as films, sheets, and synthetic products.

By creating fine fibrillar networks within the material, fibrillation enhances mechanical properties, improves uniformity, and increases overall processability.

The technique is widely used in sectors like packaging, technical textiles, and synthetic ropes, where material consistency, strength, and durability are critical for performance.

Spark Machinery specializes in providing fibrillation solutions that deliver precise and repeatable results, tailored to industrial production requirements.

How Fibrillation Works in Packaging Materials

In industrial packaging, fibrillation begins when polymer materials—such as films, sheets, or synthetic substrates—are fed into specialized processing equipment. The material passes through shafts, cylinders, and bars designed to mechanically engage the surface, generating distributed shear forces that separate and align polymer chains into microscopic fibrils. This step-by-step transformation enhances the material’s structural integrity, improving mechanical strength, flexibility, and uniformity.

The Role of Shear in the Fibrillation Process

Controlled shear forces are the primary mechanism driving fibril formation. As polymer materials pass through the fibrillation equipment, precise shear aligns and separates polymer chains into fine microfibrils. Maintaining accurate shear intensity and distribution is essential for consistent fibrillation, ensuring uniform mechanical properties, structural integrity, and stable performance across production runs.

Under-Fibrillation vs. Over-Fibrillation

Insufficient shear results in under-fibrillation, producing weak, uneven material with reduced flowability and mechanical strength. Excessive shear, on the other hand, leads to over-fibrillation, which can compromise processing stability, dimensional consistency, and durability. Proper calibration of equipment and processing parameters is critical to achieving optimal fibril development and maximizing efficiency, homogeneity, and product performance.

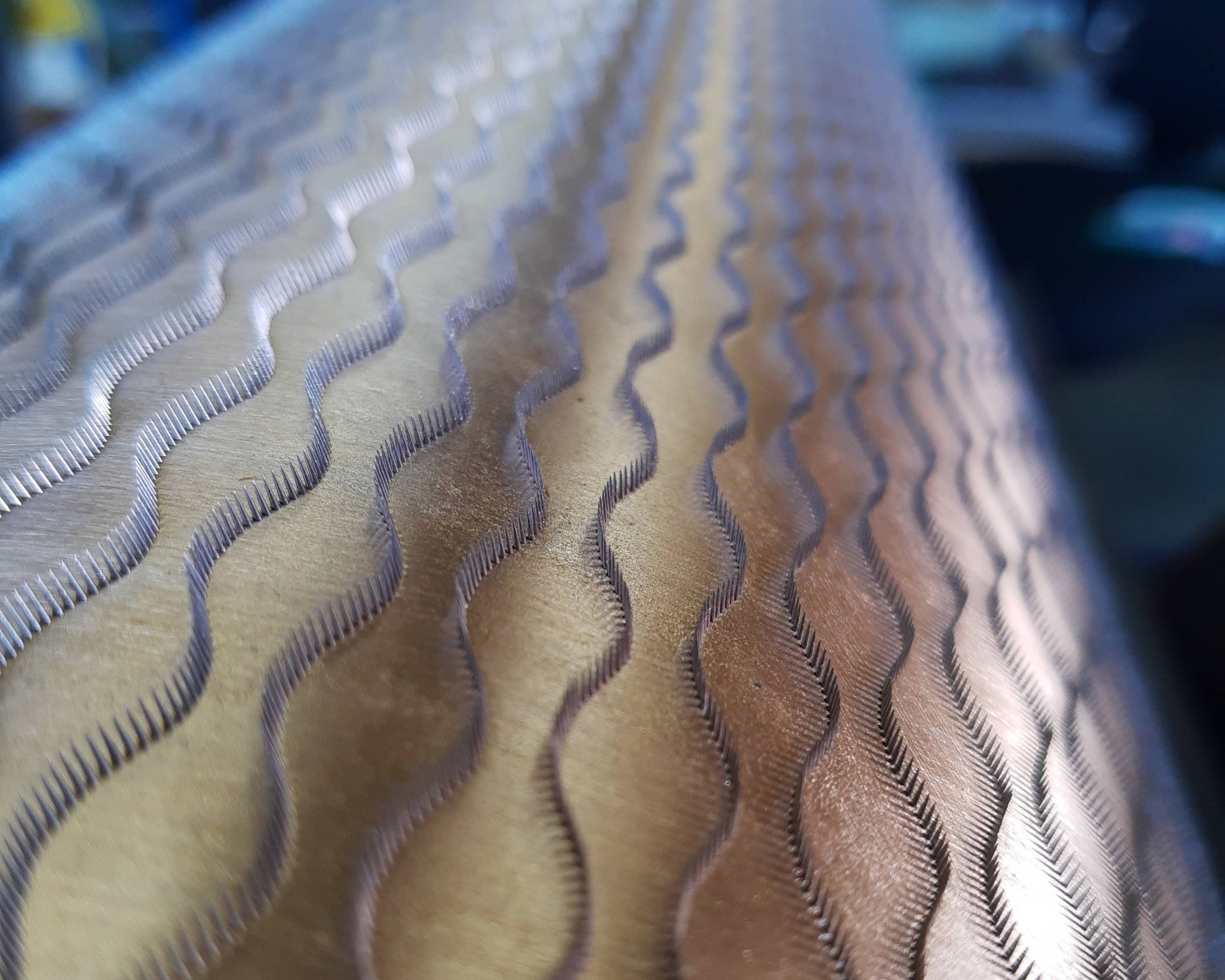

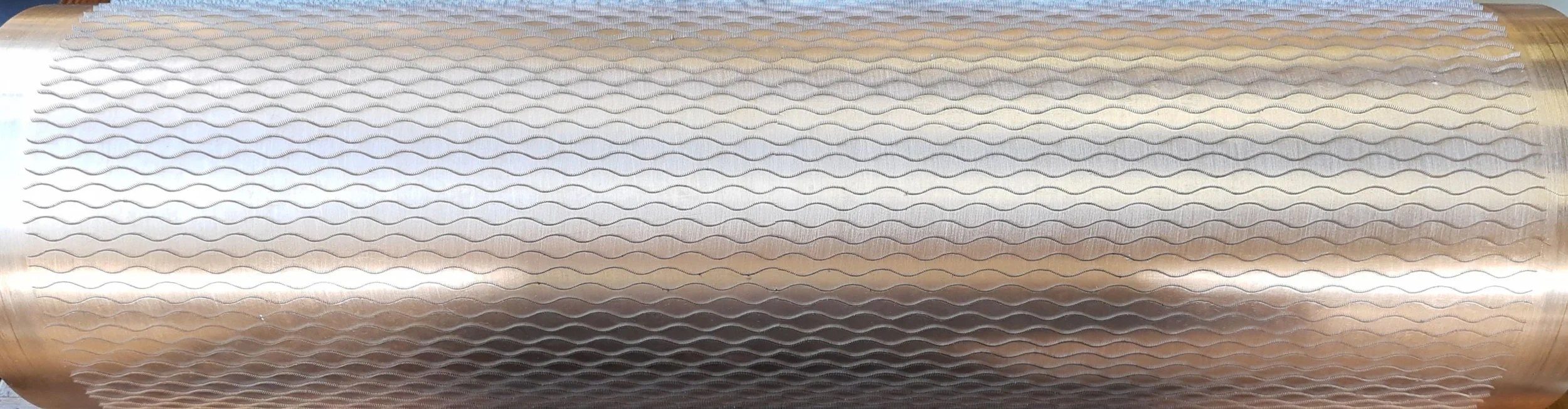

Mechanical microfibrillation of polymer surfaces

The Role of Fibrillation Shafts in Industrial Applications

Fibrillation shafts are critical for controlling the structural transformation of synthetic fibers and polymer materials in a wide array of industrial products. By precisely transferring mechanical energy to the substrate, these shafts initiate and regulate the development of fibrillar networks that determine the final product’s performance characteristics. In applications such as synthetic turf, carpet and rug backings, ropes, sewing threads, marine cables, and PTFE staple fibers, shafts enable uniform fibrillation, consistent surface texture, and reliable dimensional stability. Their design—geometry, groove pattern, and rotational speed—directly influences material behavior, production throughput, and quality consistency, making them indispensable for industries where mechanical performance and material integrity are essential.

Key Factors Influencing Packaging Fibrillation

Consistent fibrillation in industrial polymer materials relies on three main factors: machine settings, needle bar configuration, and material formulation. Controlling these elements effectively ensures uniform, high-quality fibrils that improve product performance, processing efficiency, and overall production reliability.

Shear Rate and Mechanical Energy

The shear applied during processing directly affects how polymer chains form microfibrils. Optimized equipment design—including shaft profiles, cylinder arrangements, and rotational speed—ensures even fibrillation while maintaining material strength. Proper shear management minimizes defects, reduces waste, and keeps production running smoothly.

Needle Bars and Pin Orientation

Needle bars are at the heart of industrial fibrillation. The number, angle, and arrangement of the pins determine how efficiently the material is transformed into fine fibrils. Different pin orientations allows manufacturers to tailor the process to different polymers and product thicknesses, ensuring consistent quality even with challenging substrates. High-quality steel bars with precision pins enhance durability, reduce maintenance downtime, and support continuous production—all while delivering uniform fibrillation and improved material properties.

Additives and Fillers

Additives and fillers influence how fibrils develop and affect material behavior. Properly formulated and well-dispersed, they enhance flexibility, strength, and processability, enabling the production of durable, consistent, and high-performance packaging materials.

Advantages of Fibrillation for Packaging Manufacturers

Fibrillation offers significant benefits for packaging manufacturers by improving material homogeneity and enhancing mechanical properties such as strength, flexibility, and durability. The process also increases processability, allowing for smoother handling, faster production speeds, and more consistent output. In addition, fibrillation can reduce overall material usage while maintaining product performance, contributing to cost savings and sustainable manufacturing. By delivering stable, high-quality results across production runs, fibrillation helps manufacturers optimize efficiency, minimize waste, and consistently meet stringent quality standards.

Why choose Spark Machinery for packaging fibrillation components?

Uncompromising Quality, Reliability & Performance

Spark Machinery designs and builds high-performance systems known for their precision, durability, and consistent output. Our machines operate reliably even under high-speed, high-demand production conditions, delivering top-tier results with minimal downtime.Tailor-Made Solutions for Every Customer

We don’t believe in one-size-fits-all. Every system is engineered based on the specific needs of our customers—whether it’s material type, production speed, perforation pattern, or integration with existing lines. This ensures optimal efficiency and seamless operation from day one.End-to-End Support

Our commitment goes beyond machine delivery. We offer expert guidance during project planning, hands-on support during installation and training, and responsive service throughout the machine’s operational life. We're your partner before, during, and after purchase.Driven by Research & Innovation

At Spark Machinery, continuous improvement is part of our DNA. We invest heavily in R&D and testing to develop cutting-edge perforation technologies, improve system capabilities, and stay ahead of evolving market demands. Innovation is what keeps our customers competitive—and we deliver it with every machine.

Get expert advice for your Converting Needs

Selecting the right fibrillation components can be challenging due to diverse technologies and material considerations. We offer a free, no-obligation consultation with our experts. Gain tailored insights on how surface fibrillation technology for synthetic materials can optimize production, enhance product quality, and improve efficiency—helping you make a strategic, high-return investment.

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

DANA NURTAZINA

Commercial Export Office

+39 3405936421