Spare Parts for Perforation Machines

High-quality spare parts are essential for ensuring the optimal performance, accuracy, and durability of perforation machines. Every component plays a crucial role — from maintaining consistent perforation quality to minimizing machine wear and unplanned downtime. Using genuine, well-engineered parts not only extends the lifespan of your equipment but also safeguards your investment by preventing costly breakdowns and production delays.

As a reliable supplier and manufacturer, Spark Machinery specializes in original spare parts for both micro and macro perforators. Our deep industry expertise and dedication to precision manufacturing ensure that every part meets the highest standards of quality and compatibility. Whether you need replacements, upgrades, or technical support, Spark Machinery provides dependable solutions that keep your perforation systems running efficiently and consistently.

Overview about our Perforation Machine Spare Parts

Spark Machinery offers a comprehensive range of spare parts designed specifically for our micro- and macroperforation systems, ensuring optimal performance and long-term reliability. Each component is engineered to meet exact specifications, guaranteeing perfect compatibility and consistent quality. From precision cutting tools and needle rollers to sensors, drive components, and control units, our genuine spare parts are built to maintain the high standards of accuracy and efficiency that Spark Machinery is known for.

Most Common Spare Parts Available

Macroperforation Systems:

Perforation hammers

Perforation dies

Complete perforation units

Solenoid valves

Pressure regulators

Pressure cylinders

Linear guides

Microperforation Systems:

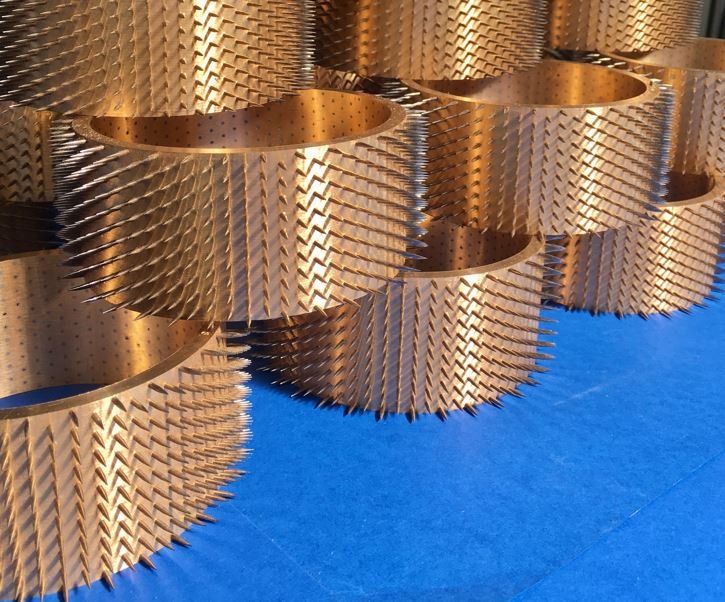

Needle rollers

Spacer cylinders

Contrast rollers

Shafts and bearings

Pneumatic actuators

Mechanical, Pneumatic, and Electronic Components:

Motors and gearboxes

Pneumatic valves and cylinders

Sensors and switches

Servo drives and control units

Custom-Made Spare Parts

Spark Machinery stands out not only for supplying original spare parts but also for its ability to deliver custom-designed components tailored to unique perforation requirements. Whether your production process demands non-standard dimensions, specialized materials, or enhanced performance under specific operating conditions, our team combines flexibility with deep engineering expertise to design and manufacture parts that meet those exact needs. By working closely with clients, we ensure that every custom solution integrates seamlessly with existing systems, maintains precision and reliability, and supports optimal efficiency — demonstrating Spark Machinery’s commitment to both innovation and practical, results-driven engineering.

Custom Needle Rollers Designed for Your Equipment

At Spark Machinery, we manufacture custom‑designed needle perforation rollers in‑house to meet the precise specifications of our customers’ perforation systems. Each roller is engineered and produced on demand, tailored to your material type, hole size, and production requirements. By controlling the entire design and manufacturing process internally, we ensure exceptional dimensional accuracy, material quality, and fit, resulting in improved durability and consistent perforation performance. This bespoke service minimizes lead times, reduces downtime, and provides you with replacement parts that integrate seamlessly with your existing equipment.

Services Related to Spare Parts

Fast Delivery & Stock Availability

Spark Machinery offers a range of flexible delivery options to meet the needs of every customer, supported by a structured spare parts management system that ensures fast and reliable service. Depending on stock availability, delivery times can range from just a few days to a few weeks. For customers requiring urgent solutions, we provide express services to minimize downtime and keep operations running smoothly.

In addition to supplying original spare parts, Spark Machinery also offers part refurbishment, die re-sharpening, and component testing, ensuring that every piece meets the highest standards of performance and reliability. This comprehensive approach guarantees not only quick delivery but also long-term operational efficiency and peace of mind for all your perforation system needs.

Installation & Technical Support

Spark Machinery provides not only flexible delivery and express services but also a range of optional support services to ensure your perforation systems operate at peak performance. In addition to supplying original or refurbished spare parts, our team can offer professional installation of machines and components by our specialized technicians, as well as remote assistance to guide you through setup, troubleshooting, or system adjustments. On-site maintenance and support are also available for critical replacements, helping to minimize downtime and ensure that every part functions reliably from the moment it’s installed.

Why Spare Parts Readiness Increases Your Efficiency

-

Keeping essential wear parts in stock allows your operations to continue smoothly, avoiding unplanned stoppages caused by unexpected component failures. With spare parts readily available, emergency repairs can be handled immediately, minimizing production interruptions and maintaining overall workflow efficiency.

-

Timely replacement of critical components ensures that your perforation systems continue to operate at peak precision. By having the right parts on hand, you can maintain consistent product quality, prevent defects, and guarantee that every batch meets your exact standards.

-

Investing in preventive maintenance with the correct spare parts helps reduce long-term operating costs. By avoiding major breakdowns, reducing emergency repairs, and extending the lifespan of your machines, you achieve a more cost-effective and sustainable operation over time.

Why choose Spark Machinery?

Uncompromising Quality, Reliability & Performance

Spark Machinery designs and builds high-performance systems known for their precision, durability, and consistent output. Our machines operate reliably even under high-speed, high-demand production conditions, delivering top-tier results with minimal downtime.Tailor-Made Solutions for Every Customer

We don’t believe in one-size-fits-all. Every system is engineered based on the specific needs of our customers—whether it’s material type, production speed, perforation pattern, or integration with existing lines. This ensures optimal efficiency and seamless operation from day one.End-to-End Support

Our commitment goes beyond machine delivery. We offer expert guidance during project planning, hands-on support during installation and training, and responsive service throughout the machine’s operational life. We're your partner before, during, and after purchase.Driven by Research & Innovation

At Spark Machinery, continuous improvement is part of our DNA. We invest heavily in R&D and testing to develop cutting-edge perforation technologies, improve system capabilities, and stay ahead of evolving market demands. Innovation is what keeps our customers competitive—and we deliver it with every machine.

Talk to our experts – We’ll guide you to the right solution

Choosing the right machine can be a complex decision — with so many models, features, and technical details to consider, it’s easy to feel unsure about which option truly fits your needs. That’s why we offer a free, no-obligation consultation to help you make a confident choice. Our experts will take the time to understand your goals, compare options, and guide you toward the best solution for your business. Let’s simplify the process together — book your free consultation today and get advice you can trust.

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

FEDERICA CANTAGALLI

Commercial Export Office