PET Perforation: Efficient Solutions for Recycling and Packaging

PET (Polyethylene Terephthalate) perforation is a precision process in which holes are created in PET packaging films to enable controlled gas and moisture exchange. This allows food products—especially fresh and respiring items—to maintain an optimal internal atmosphere, reducing condensation and extending shelf life without compromising film strength or clarity.

In this article, we explain why PET perforation is necessary, how it improves food packaging performance, the typical technical parameters involved, and the applications where it delivers the greatest value in industrial packaging lines.

Key Facts about PET Perforation

Why perforation is needed: PET films have low natural gas permeability. Perforation enables controlled O₂ and CO₂ exchange, preventing condensation and maintaining optimal conditions for fresh and respiring foods.

Key benefits: Extended shelf life, reduced moisture buildup, improved product freshness, and full compatibility with Modified Atmosphere Packaging (MAP).

Typical performance: Laser and hot-needle micro-perforation typically produce hole sizes of 40–200 microns, while macro punching creates larger openings for higher gas exchange. Industrial systems operate up to 400 m/min, depending on technology and pattern.

Applications: Fresh produce, bakery items, meat and seafood, ready-to-eat foods, and snack packaging

Understanding PET Perforation and Its Importance

What Is PET Perforation?

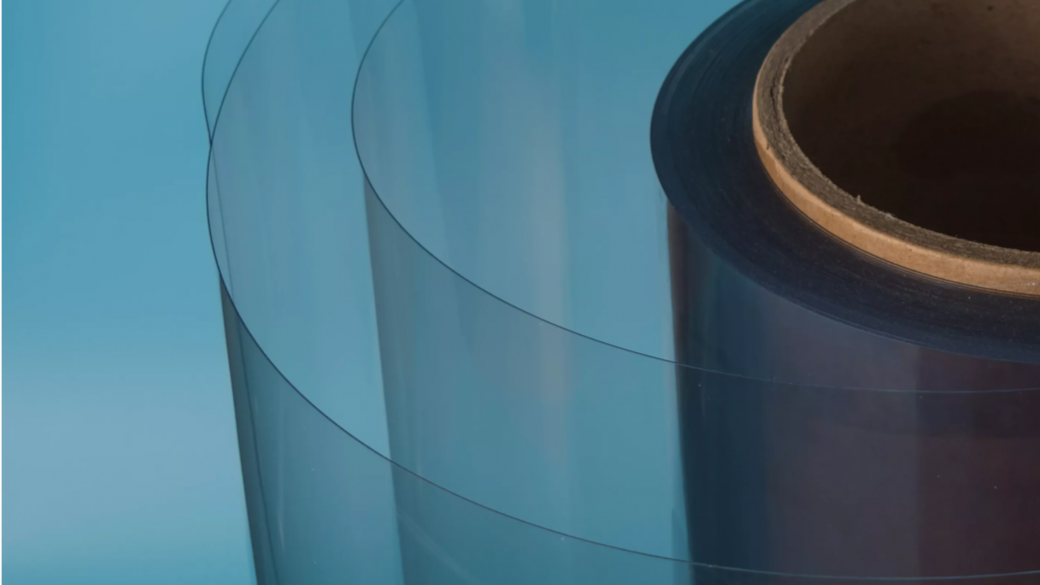

PET (Polyethylene Terephthalate) is a strong, lightweight, and transparent thermoplastic widely used in food and beverage packaging, including bottles and films, due to its excellent barrier properties, chemical resistance, and recyclability.

Why PET films are perforated: Before packaging, PET films are perforated to allow controlled gas and moisture exchange. This prevents condensation, reduces spoilage, and maintains product quality, especially for fresh and respiring foods, while preserving the mechanical strength and clarity of the film.

Applications in Recycling and Packaging

Produce Packaging with Perforated Films

Extended freshness and shelf life: Controlled gas exchange balances O₂ and CO₂, slowing spoilage of fruits, vegetables, and leafy greens.

Condensation prevention: Reduces internal moisture, preserving texture, appearance, and flavor.

MAP compatibility: With micro perforation, optimizes modified-atmosphere packaging without compromising film strength.

Sustainability Advantages

Material efficiency: Thinner films perform effectively due to micro-perforation, reducing plastic use.

Food waste reduction: Longer shelf life helps decrease food spoilage.

Recyclability: PET retains its structural properties, supporting closed-loop recycling systems.

Types of PET Perforators and Technologies

Spark Machinery provides multiple perforation technologies for PET films and lidding materials, including macro punching, hot needle perforation, and laser perforation, allowing the process to be precisely matched to the application. Macro punching is a mechanical technique that produces larger, uniform holes, ideal for products with higher respiration rates or packages requiring rapid air and moisture release. Hot needle perforation creates clean, thermally sealed holes that reduce the risk of tearing, while laser perforation enables extremely precise micro-holes for controlled gas exchange. All methods preserve PET’s mechanical strength, optical clarity, and process stability.

Perforation Patterns

Linear / grid patterns: Uniformly arranged holes provide consistent gas exchange and high structural stability.

Random / staggered patterns: Evenly distribute mechanical stress across the film, reducing the risk of tearing while maintaining breathability.

Custom densities: Hole size, spacing, and pattern are engineered based on product type, respiration rate, and storage conditions.

Impact on Product Freshness

Perforation design directly controls the exchange of O₂ and CO₂ inside the package. Optimized perforation patterns help minimize condensation, slow spoilage of fresh products, and ensure uniform freshness across all packages, without compromising PET film integrity or recyclability.

Key Technical Specifications and Design Considerations

Throughput and Perforation Rate

In Spark Machinery’s HN (Hot Needle), PU (Punching), and LO (Laser) machine series, throughput and perforation rate are key drivers of overall productivity. Throughput (m/min) defines how much PET film can be processed within a given time and directly impacts line capacity and operating efficiency. Higher throughput allows continuous, high-speed production without bottlenecks, provided perforation quality remains consistent.

The perforation rate indicates the accuracy and completeness of hole formation according to the defined pattern. A high perforation rate ensures predictable gas and moisture exchange, stable packaging performance, and minimal scrap or reprocessing. Together, optimized throughput and high perforation efficiency enable the HN, PU, and LO series to deliver reliable performance, consistent quality, and maximum productivity in industrial PET film processing.

Best Practices for Operation, Safety and Maintenance

Installation and Retrofitting Tips

For optimal performance, Spark Machinery perforators should be installed in a stable, well-aligned position within the production or processing line to ensure consistent film tension and accurate perforation. When retrofitting existing lines, adequate upstream and downstream clearance is essential to allow smooth material flow and avoid film folding or overlap. Perforators should be integrated with appropriate feeding systems to maintain constant speed and alignment, and enclosed with certified safety guards to protect operators while allowing easy access for inspection and servicing. Proper electrical and control integration ensures synchronized operation with the rest of the line.

Maintenance and Service

Regular maintenance is critical to maintaining high perforation quality and machine reliability. Mechanical tools such as punches and dies should be periodically inspected and sharpened or replaced to prevent incomplete perforations or film damage. Anti-jamming and film-guiding systems must be checked routinely to ensure uninterrupted operation, especially at higher throughputs. Spark Machinery recommends scheduled preventive maintenance based on operating hours, including tool inspection, drive system checks, and cleaning, to minimize downtime and extend equipment lifespan.

Environmental Impact and Sustainability Benefits

Supporting the Circular Economy

Spark Machinery’s perforation systems play a key role in advancing sustainable packaging by preserving the performance and recyclability of PET films throughout their lifecycle. By creating precise micro- or macro-perforations, our technology maintains the structural integrity of the film while enabling controlled gas and moisture exchange for fresh products. This ensures that the film can perform effectively in packaging applications while remaining fully compatible with recycling processes.

In addition, perforated PET films help reduce material usage by allowing thinner films to achieve the same performance, and they extend product shelf life by minimizing spoilage and condensation. Together, these benefits reduce waste, lower the environmental footprint of packaging, and support a circular economy model in which PET can be efficiently collected, reprocessed, and reused in new products. Spark Machinery’s solutions therefore not only improve packaging performance but also enable companies to meet sustainability goals and adopt environmentally responsible practices across their operations.

Frequently Asked Questions

-

PET perforators create precise micro- or macro-holes in the film using mechanical or laser technology. These holes allow controlled gas and moisture exchange while preserving the film’s strength and clarity.

-

Throughput depends on film width, thickness, and perforation pattern, but Spark Machinery systems typically handle up to 400 meters per minute, ensuring high productivity without compromising hole quality.

-

Yes, our systems are designed to process PET films of varying thicknesses and compositions, including single-layer and laminated films used for food packaging.

-

Regular inspection and replacement of perforation tools or laser optics are essential to maintain hole quality and consistent performance. Tools are designed for long life, reducing downtime.

-

Absolutely. Spark Machinery’s perforation processes are compatible with food-grade PET films and meet industry standards for hygiene, safety, and barrier performance.

-

Hole size, density, and pattern are tailored to the product’s respiration rate. Properly designed patterns optimize O₂ and CO₂ exchange, extend shelf life, and prevent condensation.

Why choose Spark Machinery for PET perforation?

Uncompromising Quality, Reliability & Performance

Spark Machinery designs and builds high-performance systems known for their precision, durability, and consistent output. Our machines operate reliably even under high-speed, high-demand production conditions, delivering top-tier results with minimal downtime.Tailor-Made Solutions for Every Customer

We don’t believe in one-size-fits-all. Every system is engineered based on the specific needs of our customers—whether it’s material type, production speed, perforation pattern, or integration with existing lines. This ensures optimal efficiency and seamless operation from day one.End-to-End Support

Our commitment goes beyond machine delivery. We offer expert guidance during project planning, hands-on support during installation and training, and responsive service throughout the machine’s operational life. We're your partner before, during, and after purchase.Driven by Research & Innovation

At Spark Machinery, continuous improvement is part of our DNA. We invest heavily in R&D and testing to develop cutting-edge perforation technologies, improve system capabilities, and stay ahead of evolving market demands. Innovation is what keeps our customers competitive—and we deliver it with every machine.

Get expert advice for your Converting Needs

Selecting the right converting machines can be challenging due to diverse technologies and material considerations. We offer a free, no-obligation consultation with our experts. Gain tailored insights on how perforation technology can optimize production, enhance product quality, and improve efficiency—helping you make a strategic, high-return investment.

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

DANA NURTAZINA

Commercial Export Office