Pre Cut Machines by Spark Machinery

Our Pre Cut Machine Models - Cross Cut

-

Cross-cutting machines are motorized equipment designed to be installed as host units in moving film production lines. These units are capable of performing cross pre-cuts on films of various materials and thicknesses, with customizable width.

-

Motorization: The unit is equipped with a motorized system to ensure optimal accuracy and speed during the cross-cutting operation on moving film.

Wide Applicability: The pre-cutting unit is suitable for processing a wide range of materials and thicknesses, allowing flexibility in use on different types of film.

Easy Integration: It can be easily integrated into existing production lines, such as extruders, slitters, printing or welding machines.

System of toothed blades: The toothed blade system allows you to obtain precise and clean cuts and guarantees a high quality finish even in the presence of difficult materials, without stretching or ruining the film.

-

The device is used to make easy-tear solutions on garbage bags, shoppers, labels, and other packaged products that require easy-opening systems. Because of its versatility and reliable performance, it is an ideal solution for improving the efficiency and quality of industrial packaging processes.

Model PC0 to make Cross pre-cuts on moving film at customizable distances

General Description

The PC0 is a motorised transverse (cross-cut) pre-cut unit designed to be installed as a host module on moving-film production lines (extruders, slitters, printing machines, welding machines, etc.).

Its primary task is to make controlled pre-cuts (partial or full) across the width of a continuous film web, for purposes such as easy-tear features on bags, shoppers, labels, and other flexible packaging formats.

Typical Applications

Addition of tear-strip or easy-open features to packaging films (bags, garbage bags, shoppers) by pre-cutting the film before final converting.

Pre-cutting webs in multi-material or laminate films, biodegradable films, non-woven webs where controlled partial cuts are needed.

Retrofit installation into existing converting lines to provide pre-cut functionality without major overhaul.

| TECHNICAL DATA SHEET | |

|---|---|

| Description | Transverse pre-cutting machine for moving film |

| Maximum Speed | 100* mt minute |

| Minimum distance between pre-cuts | 150 mm |

| Type of pre-cut | Transverse |

| Position of the pre-cutting blades | On blade shaft |

| Max no. of blades | 2 |

| Blade shaft movement | Brushless motor with driver and encoder |

| Air pressure | Min. 6 bar |

| Voltage | 400+T-50 V-Hz |

| Compressed air hose inlet | Min. 12 externally calibrated tube |

| Penetration adjustment | Manual |

| Drive | Electronics with 4.0 integration |

| * | Value affected by the type of processed material |

For more detailed information click on the link below

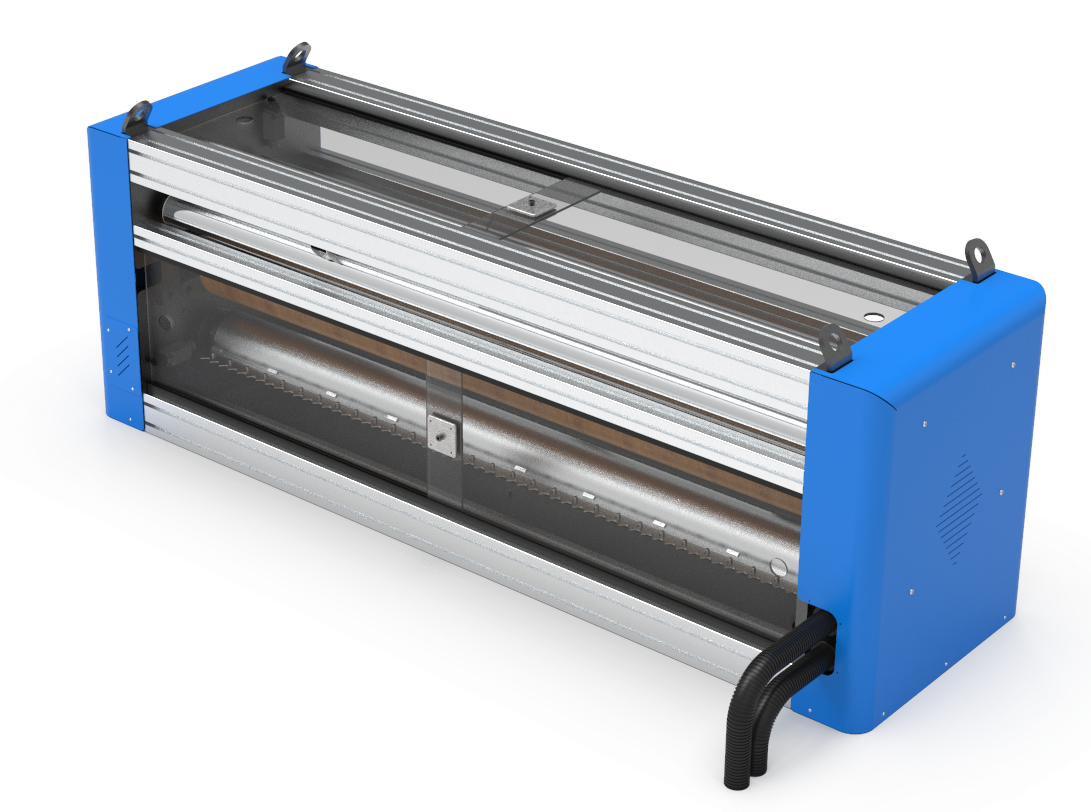

Model PC200 to make Cross pre-cuts on moving film at customizable distances

General Description

The PC200 is a motorised pre-cutting machine designed for transverse (cross-cut) pre-cuts of moving web films. It is intended to be integrated as a unit into converting lines (extruders, slitters, bag-making machines, printing lines, welders, etc.) and is capable of handling a wide variety of film and sheet materials with customisable width.

It enables “easy-tear” or partial cut features (for example in bags, shoppers, labels) by pre-cutting moving film webs without fully severing them.

The unit is designed to be placed inline: the film web arrives, passes between the blade roller and the support roller; when the two rollers are pneumatically engaged, the blade roller plunges (to an adjustable depth) into the film material to create the pre-cut while the support roller backs the film.

| TECHNICAL DATA SHEET | |

|---|---|

| Maximum Speed | 200 mt minute |

| Minimum distance between pre-cuts | 60 mm |

| Type of pre-cut | Transverse |

| Position of the pre-cutting blades | On blade shaft |

| Max no. of blades | 4 |

| Blade shaft movement | Brushless motor with driver and encoder |

| Air Pressure | Min. 6 Bar |

| Voltage | 400+T-50 V-Hz |

| Compressed air hose inlet | Min. 12 externally calibrated tube |

| Penetration adjustment | Manual |

| Drive | Electronics with 4.0 integration |

| * | Value affected by the type of processed material |

The PC200 is capable of processing a broad range of materials, including but not limited to:

PP (Polypropylene), PET, PVC, LDPE, HDPE, BOPP, CPP, laminated films, compostable/biodegradable films.

Leather, eco-leather, synthetic leather, non-woven materials, Tyvek, foam, raffia, paper, multilayer paper, single-use table mats, labels.

Summary

In short, the PC200 is a high-speed, synchronised transverse pre-cut unit for moving film webs, offering flexibility (material types, adjustable cut spacing & depth), Industry 4.0-enabled control, and integration friendly design. It supports up to about 200 m/min (depending on material) and minimal cut spacing of 60 mm.

For more detailed information click on the link below

Our Pre Cut Machine Models - Longitudinal cut

-

Longitudinal pre-cutting machines are motorized devices designed to be installed as host units in moving film production lines. These units are capable of performing longitudinal pre-cuts on films of various materials and thicknesses, with customizable widths and distances.

-

Versatility: The PC-BP is an extremely versatile machine for making longitudinal cuts of various lengths and at customizable distances. The circular blades are interchangeable, designed for easy replacement when working needs to be changed.

Efficiency: The PC-BP is a motorized unit with a synchronization system to ensure perfect and homogeneous cuts on a variety of materials and for numerous applications.

Adaptability: With its flexibility and versatility, the unit adapts to a wide range of production needs in industrial packaging.

Easy Integration: The device can be easily integrated into existing production lines, such as extruders, welding machines, slitters, bag-making machines, printing machines, and all moving film processing lines.

-

Longitudinal pre-cutting units find wide use in the packaging industry for the production of breathable films, bags and pouches with easy openings, and nets for fruit and vegetable packaging.This model is ideal for improving the convenience and functionality of packaged products by allowing optimal air passage and easy openings.

Model PC-BP Longitudinal Cutting Machine for cutting at customizable distances

The PC‑BP is a motorized longitudinal pre‑cutting unit designed to perform precise partial cuts along the direction of the film web travel. It is intended for inline integration into film converting and processing lines such as extruders, slitters, printing machines, laminators, or welding units. The unit allows continuous production of longitudinal pre‑cuts without stopping the web, making it suitable for high‑speed industrial applications.

The PC‑BP is equipped with a blade roller featuring interchangeable circular blades and a pneumatically actuated support roller, which provides backing during the cutting process. The penetration depth of the blades is fully adjustable via micrometric screws, enabling operators to control the cut depth with high precision, from shallow tear lines to deeper partial cuts, while maintaining the integrity of the web.

| TECHNICAL DATA SHEET | |

|---|---|

| Description | "Cold" longitudinal pre-cutting machine for moving film |

| Blade roller Ø | 60mm – 100mm - 200mm |

| Lenght of cuts | Max 15mm |

| Minimum distance between cuts | 2mm |

| Movement | Via asynchronous motor 400 V+N+T - 50 Hz |

| Speed synchronization between blade roller and moving film | Synchronization system with driver and encoder |

| Penetration adjustment | Micrometric screws with graduated knobs |

| Max. Speed | 300* meters/minute |

| Counter roller approach movement | Pneumatic movement |

| Air Pressure | 6 BAR |

| * | Value influenced by material type and machine configuration |

For more detailed information click on the link below

How Does a Pre Cut Machine Work?

Working Principle of Pre-Cut Machines

Pre-cut machines create controlled cuts in continuous web materials like film, paper, or nonwovens — ideal for easy-open packaging, bag production, and roll converting.

1. Web Feed & Control:

The moving web passes through tension and guiding systems to ensure perfect alignment and stable speed.

2. Cutting Station:

Rotary shafts equipped with precision circular blades perform the cutting. The web runs between the blades and a backup (contrast) roller for clean, accurate cuts.

3. Cutting Types:

Longitudinal Pre-Cut: Multiple blades slit the web lengthwise into narrower lanes or create easy-tear lines.

Cross Pre-Cut: Circular blades make short transverse micro-cuts for controlled tearing or easy opening.

4. Integration:

Pre-cut modules can be seamlessly installed in existing production or converting lines, synchronized with line speed and registration sensors for exact positioning.

5. Precision & Quality:

Micrometric blade adjustment and servo control ensure consistent cut depth, repeatability, and minimal material stress — key for high-speed packaging and converting applications.

Advantages of Pre Cut Machines

Key Benefits of Blade Pre-Cut Technology

Precision Cutting: Consistent, high-quality cuts with micrometric adjustment for different materials and thicknesses.

Higher Production Efficiency: Continuous, in-line operation minimizes manual handling and boosts throughput.

Improved Product Usability: Creates easy-open or tear-assist features that enhance the end-user experience.

Material Savings: Optimized cutting patterns reduce waste and maximize usable web area.

Reduced Downtime: Durable blades and quick-change designs enable fast maintenance and setup.

Customization Flexibility: Configurable blade types, spacing, and cutting depth adapt to specific products and production needs.

Why choose Spark Machinery?

Uncompromising Quality, Reliability & Performance

Spark Machinery designs and builds high-performance systems known for their precision, durability, and consistent output. Our machines operate reliably even under high-speed, high-demand production conditions, delivering top-tier results with minimal downtime.Tailor-Made Solutions for Every Customer

We don’t believe in one-size-fits-all. Every system is engineered based on the specific needs of our customers—whether it’s material type, production speed, perforation pattern, or integration with existing lines. This ensures optimal efficiency and seamless operation from day one.End-to-End Support

Our commitment goes beyond machine delivery. We offer expert guidance during project planning, hands-on support during installation and training, and responsive service throughout the machine’s operational life. We're your partner before, during, and after purchase.Driven by Research & Innovation

At Spark Machinery, continuous improvement is part of our DNA. We invest heavily in R&D and testing to develop cutting-edge perforation technologies, improve system capabilities, and stay ahead of evolving market demands. Innovation is what keeps our customers competitive—and we deliver it with every machine.

Applications of our Pre Cut Machines

Typical Applications

Blade pre-cut systems are used across many packaging and converting industries to improve functionality and efficiency:

Breathable Films: Create fine slits or micro-cuts to control air permeability for hygiene, medical, or agricultural films.

Easy-Tear Packaging: Add controlled tear lines in bags, pouches, and sachets for effortless opening.

Net Packaging for Fruit & Vegetables: Pre-cut plastic or mesh webs for clean, uniform bag production.

Garbage Bags with Easy-Open Function: Integrate tear-assist cuts or pre-scored lines for quick separation and convenience.

Retail Shoppers & Carry Bags: Produce consistent tear lines or handle perforations for automated bag conversion.

Labels, Tags & Tear-Off Solutions: Precise pre-cuts simplify detachment of individual labels, coupons, or ticket sections.

Get expert advice for your Perforation Needs

Choosing the ideal pre-cut machine can be a complex decision, given the diverse technologies and material considerations involved. To ensure you select the perfect solution for your specific needs, we invite you to a free, no-obligation consultation with our experts. Benefit from personalized insights into how the right hot, cold, or laser perforation technology can optimize your production, enhance product quality, and drive efficiency, ensuring a smart investment tailored to your success.

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

DANA NURTAZINA

Commercial Export Office