Bopp perforation: everything you need to know about micro and macro perforation

Biaxially Oriented Polypropylene (BOPP) film is often perforated to optimize ventilation, allowing controlled airflow while maintaining the film’s structural integrity. This perforation enhances product freshness and prevents condensation, making it particularly suitable for applications in the food, agricultural, and automotive sectors. In the food industry, perforated BOPP helps extend the shelf life of fresh produce and packaged goods. In agriculture, it supports the storage and transportation of crops by reducing moisture accumulation. In the automotive sector, ventilated films are used in protective coverings and packaging components where airflow is critical.

Key facts at a glance

Definition:

Biaxially Oriented Polypropylene (BOPP) film is a high-strength, lightweight polypropylene film stretched in both machine and transverse directions. Perforated versions allow controlled airflow.

Perforation Types:

Micro-perforation: Tiny holes for gentle ventilation; ideal for fresh produce.

Macro-perforation: Larger holes for high airflow; used in bulk storage and industrial packaging.

Key Benefits:

Regulates moisture and prevents condensation

Extends product shelf life

Maintains structural integrity and clarity

Typical Applications:

Food: Fresh produce, bakery goods, snacks

Agriculture: Crop storage and transport

Automotive: Protective covers and component packaging

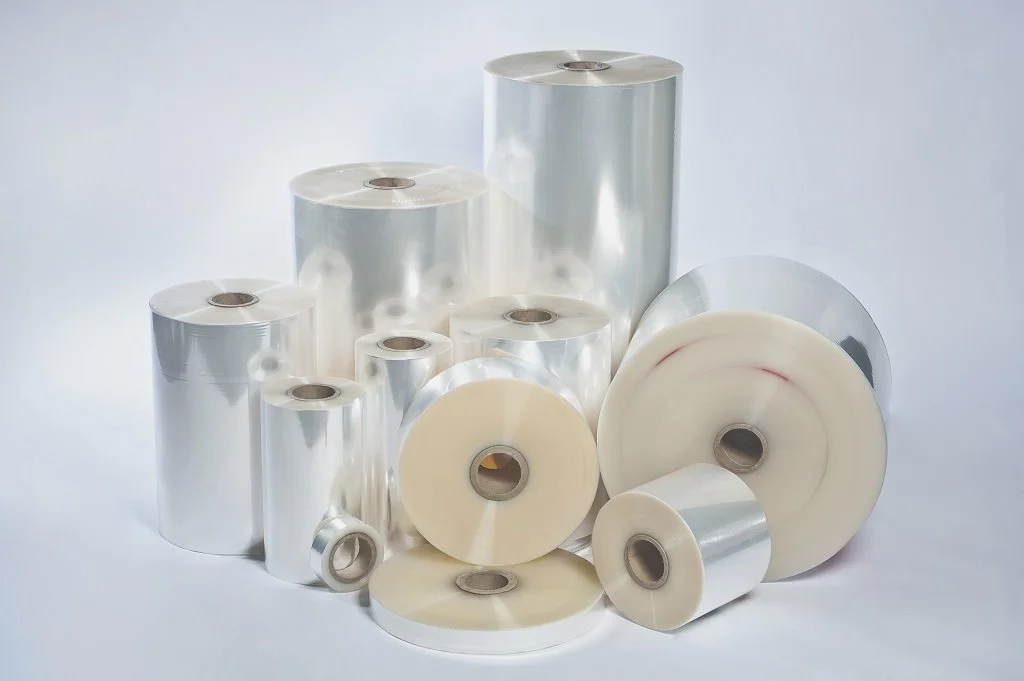

What is BOPP film?

Manufacturing and characteristics of BOPP

Biaxial Orientation of Polypropylene (BOPP)

Biaxial orientation refers to the process in which polypropylene film is stretched in both the machine direction (MD) and transverse direction (TD). This dual-axis stretching aligns the polymer chains, enhancing mechanical and physical properties compared to non-oriented polypropylene:

Improved Tensile Strength: Biaxial orientation increases resistance to stretching and breaking under tension, making BOPP highly durable.

Dimensional Stability: The film resists shrinking or warping under stress or temperature changes.

-

BOPP films are naturally highly transparent, offering excellent clarity and gloss. This makes them ideal for applications where product visibility is important, such as food packaging and retail overwraps. Transparency can also be modified by adding mattifying agents or coatings without compromising strength.

-

Biaxial orientation enhances tear resistance, giving the film the ability to withstand punctures and handling stress during packaging, transport, and display. The tear strength is generally directional, with slightly higher resistance along the machine direction.

-

The smooth, non-porous surface of BOPP film allows for high-quality printing, including flexographic, gravure, and rotogravure techniques. Printability is often further enhanced through corona or plasma treatment, which increases surface energy and ensures strong ink adhesion. This property is crucial for branding and product labeling.

How does the perforation work? (Micro vs. Macro)

| Feature | Micro Perforation | Macro Perforation |

|---|---|---|

| Hole Characteristics | Invisible pores (50 µm – 1 mm). Preserves the "glass-like" clarity of BOPP. | Large, functional holes (2 mm – 10 mm). High visibility for airflow. |

| Primary Function | Modified Atmosphere (MAP). Extends shelf life by controlling gas exchange. | High Ventilation. Prevents moisture build-up and "sweating" in packaging. |

| Technical Method | Precision Laser or Hot Needle to ensure sealed, tear-resistant edges. | Mechanical Punching; maintains film stiffness and tensile strength. |

| Protection Level | Blocks pollutants and UV while allowing the product to "breathe" slowly. | Maximum airflow; ideal for products that release intense heat or steam. |

| Best Applications | Ready-to-eat salads, berries, and pharmaceutical overwraps. | Freshly baked bread, hot produce, and floral packaging. |

| BOPP Advantage | High-speed sealability remains intact; graphics appear printed on the product. | Resists wrinkling and shrinkage even with high-density perforations. |

Benefits of perforated BOPP

Breathability and Moisture Control

Perforated BOPP film allows excess vapor to escape through precision-engineered holes, preventing internal condensation. This stable, dry environment eliminates moisture accumulation, significantly reducing mold risk and preserving product quality during transport.

Extending the Shelf Life of Food

Perforated BOPP creates a balanced microclimate that extends product shelf life. It prevents sogginess and mold in bakery items by venting excess humidity, while allowing fruits and vegetables to respire properly. By maintaining freshness and slowing spoilage, this packaging significantly reduces food waste throughout the supply chain.

Economic and Ecological Benefits

Perforated BOPP reduces spoilage and rejected goods, lowering supply chain costs while its high gloss enhances retail appeal. Ecologically, its lightweight design improves material efficiency, and it remains fully recyclable within polypropylene streams, supporting a lower environmental footprint.

Fields of application for perforated BOPP films

Selection Criteria for BOPP Perforation

Choosing the right perforation technology is a balance between material science and mechanical precision. To ensure film integrity and product safety, purchasers must evaluate three critical technical pillars.

-

The effectiveness of a perforated film is measured by its Air Exchange Rate (AER).

Precision: The machine must maintain absolute uniformity. For micro-perforation, a variation of even 20 microns can drastically alter the internal atmosphere, leading to premature food spoilage.

Density: High-performance machinery allows for adjustable patterns, enabling users to switch between high-density micro-pores for fast-respiring produce (like mushrooms) and lower-density patterns for slower-respiring items.

-

BOPP is a high-stiffness film that is susceptible to "crack propagation" or zippering if the perforation is not executed correctly.

Thermal Reinforcement: Whether using laser or hot-needle, the machine must melt the edges of the hole. This creates a reinforced beaded rim that prevents the film from tearing during high-speed winding or when the customer opens the package.

Tension Management: The equipment must handle thicknesses from 15 to 50+ microns without stretching the film, which would otherwise distort the hole geometry.

-

In food and pharmaceutical sectors, the perforation process must be as "clean" as the material itself.

Contamination-Free: Mechanical punching produces "slugs" (waste circles) that must be 100% vacuum-extracted to avoid falling into food. Laser systems are often preferred here as they vaporize the material, leaving zero physical residue.

Industry Certifications: Machinery should be compatible with clean-room standards and use food-grade lubricants and materials to ensure that the perforated film remains FDA/EU compliant for direct food contact.

Spark Machinery: The Professional’s Choice

Our perforation systems are engineered specifically for the unique demands of Biaxially Oriented Polypropylene. We provide the control you need to master gas exchange, ensure film strength, and meet the highest safety standards in the industry.

Tips for buying and handling

When purchasing a perforation machine, the technical integrity of the output is your most important metric. High-quality machinery must produce films with uniform clarity and a consistent "slip" level to ensure seamless integration with your existing packaging lines. During equipment trials, pay close attention to the perforation edges; they should be smooth and slightly thickened (beaded) to the touch. This reinforced melt-fringe is a hallmark of superior thermal or laser processing, ensuring the film can withstand high-tension winding without "zippering" or tearing.

Key Quality Indicators for Machinery

Hole Consistency: Absolute uniformity across the web width is mandatory. Irregular hole sizes indicate poor laser calibration or uneven needle heating, which will compromise the product’s shelf life.

Tension Control: The machine must feature precise winding and unwinding controls to avoid "blocking" (layers sticking together) or "telescoping" of the finished roll.

Debris Extraction: High-end systems should be entirely free of "slugs" or plastic residue, utilizing powerful vacuum extraction or vaporization to meet food-grade cleanliness standards.

Operational Handling and Storage

Environment: Ensure your facility can store film at 15–25°C away from sunlight to protect sensitive anti-fog and slip additives from degradation.

Acclimatization: Plan for a 24-hour stabilization period in the production area. This minimizes static and tracking issues during high-speed runs.

Support Systems: Use equipment that allows rolls to be stored horizontally or suspended by the core. This prevents "flat spots" on the film, which otherwise cause vibrations and registration errors during the perforation process.

Talk to our experts – We’ll guide you to the right solution

Selecting the right perforation system is a high-stakes decision where even a few microns can be the difference between a fresh product and a rejected batch. Between balancing gas-permeability, material "zipper" resistance, and precise air exchange rates, the technical variables can be overwhelming.

Don't leave your production quality to chance. Our experts at Spark Machinery can help you navigate these complexities to find the exact technology for your specific application.

Ready to optimize your production? Book Your Free Technical Consultation

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

FEDERICA CANTAGALLI

Commercial Export Office