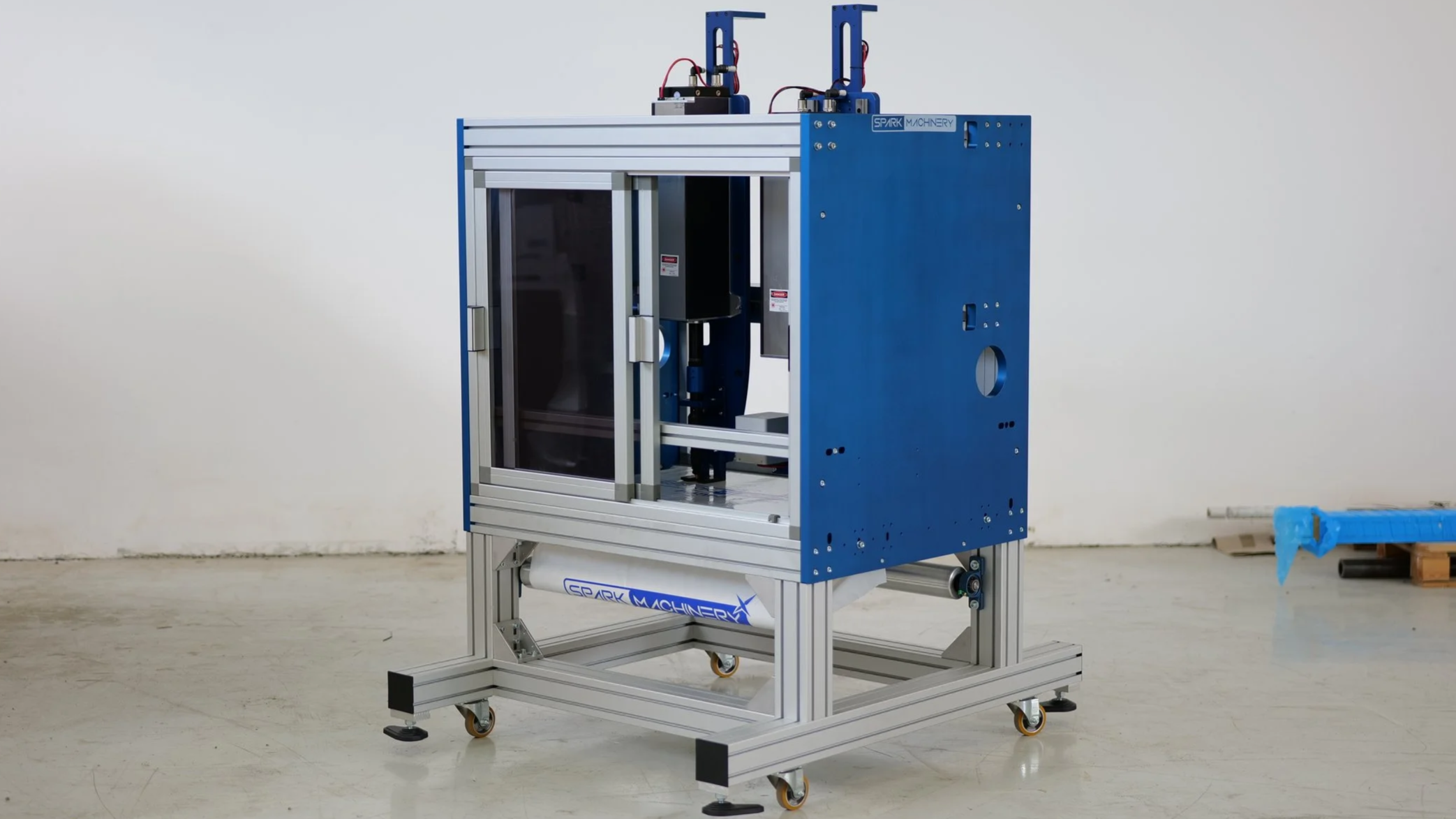

Laser Micro Perforation Machines by Spark Machinery

Our Laser Micro Perforators

Series: LO Series

Function: High-precision laser micro-perforation, scoring, pre-cutting, and engraving of moving film webs, enabling controlled and repeatable material processing without mechanical contact.

Applications: Designed for advanced packaging needs including MAP/EMAP packaging, easy-open features, and breathable films used across food, pharmaceutical, and automotive sectors. Ensures extended shelf life, user convenience, and optimal material performance.

Technology: CO₂ laser-based systems equipped with galvanometric scanning heads (Model LO-S40) and adjustable parameters including pulse frequency, laser energy, and processing speed. Supports full integration with vision inspection and control systems for real-time monitoring and alignment. Industry 4.0-ready architecture with touchscreen control, recipe management, and remote diagnostics capability.

Model LASER ONE MICRO perforation LASER system for 40µm to 200µm holes and pre-cuts

Operation

The film, kept under constant tension by idler rollers, passes through the system where a CO₂ laser emits infrared beams. These are expanded via a beam expander and focused by a lens onto the film surface. Micro-perforation is performed through thermal sublimation of the material.

Control & Adjustment

The LASER‑ONE system is managed via Industry 4.0-ready software on a touchscreen panel. Operators can adjust pulse frequency, hole diameter, and position. The laser can perform both full perforation and scoring (partial depth weakening) for features like easy-open lines.

| TECHNICAL DATA SHEET | |

|---|---|

| Product | Laser perforation system |

| Laser Source Type | CO2 laser source |

| Hole Ø | Min. Ø40µm |

| Maximum Speed | 250* meters/minute |

| Maximum power of the laser source | 1500W* |

| Control system | Control panel with custom PLC and PC with remote assistance |

| Software | 4.0 integration and recipe management (insertion, storage, recall) |

| Cooling system | Liquid |

| Accessories | Encoder and Photocell |

| * | Value influenced by the type of processed material and machine configuration |

For more detailed information click the link below

Model LO-S40 Scanning LASER MICRO perforation system, for 70µm to 200µm holes, pre-cuts and engraving

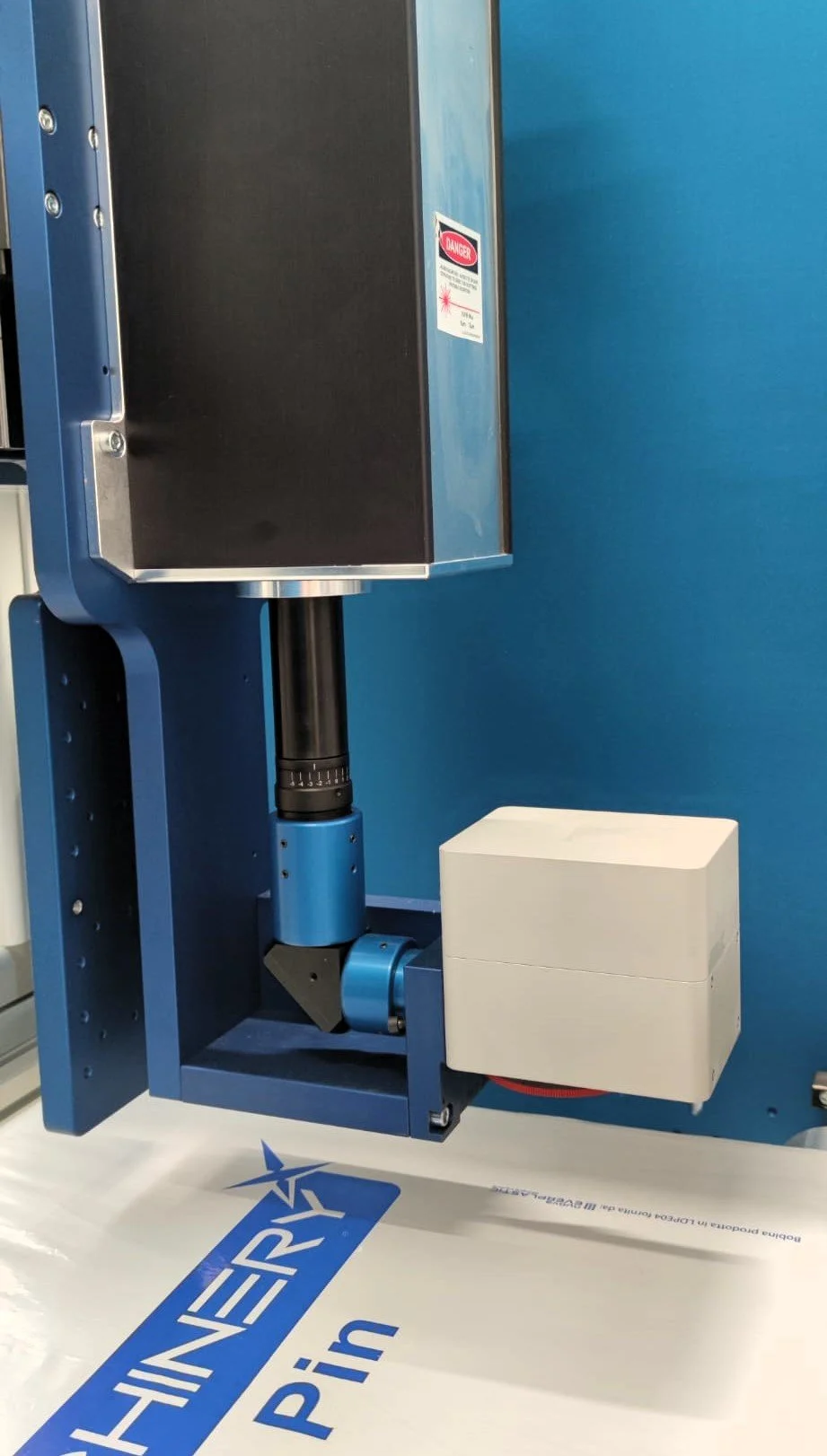

Operation

The film, tensioned by idler rollers, is processed by a CO₂ laser emitting infrared beams. These are expanded, then steered by high-speed motorized scanning mirrors, enabling precise, dynamic positioning of each perforation. A focusing lens concentrates the beam onto the film, achieving micro-perforation via thermal sublimation.

Control & Adjustment

The LO-S40 is equipped with Industry 4.0-ready software and a touchscreen interface. Operators can control laser pulse, hole size, position, and manage each scanning head independently to define complex patterns. An integrated camera system (optional) provides real-time visual feedback for alignment, quality control, and process validation.

The system supports both micro-perforation and scoring (partial material weakening) for applications like easy-open features.

| TECHNICAL DATA SHEET | |

|---|---|

| Product | Scanning Laser perforation system |

| Number of laser sources installed | Minimum 1 laser source -> Maximum 6 laser sources |

| Hole Ø | Ø Min. 70µm |

| Max Speed | 380* meters/minute |

| Software | 4.0 integration and recipe management (insertion, storage, recall) |

| Control system | Control panel with custom PLC and PC with remote assistance |

| Maximum power of the laser source | 1500W* |

| Signal Resolution | 10 micro seconds |

| Pulse frequency | maximum frequency 50 kHz |

| Cooling System | Liquid |

| * | Value influenced by the type of processed material and machine configuration |

For more detailed information click the link below

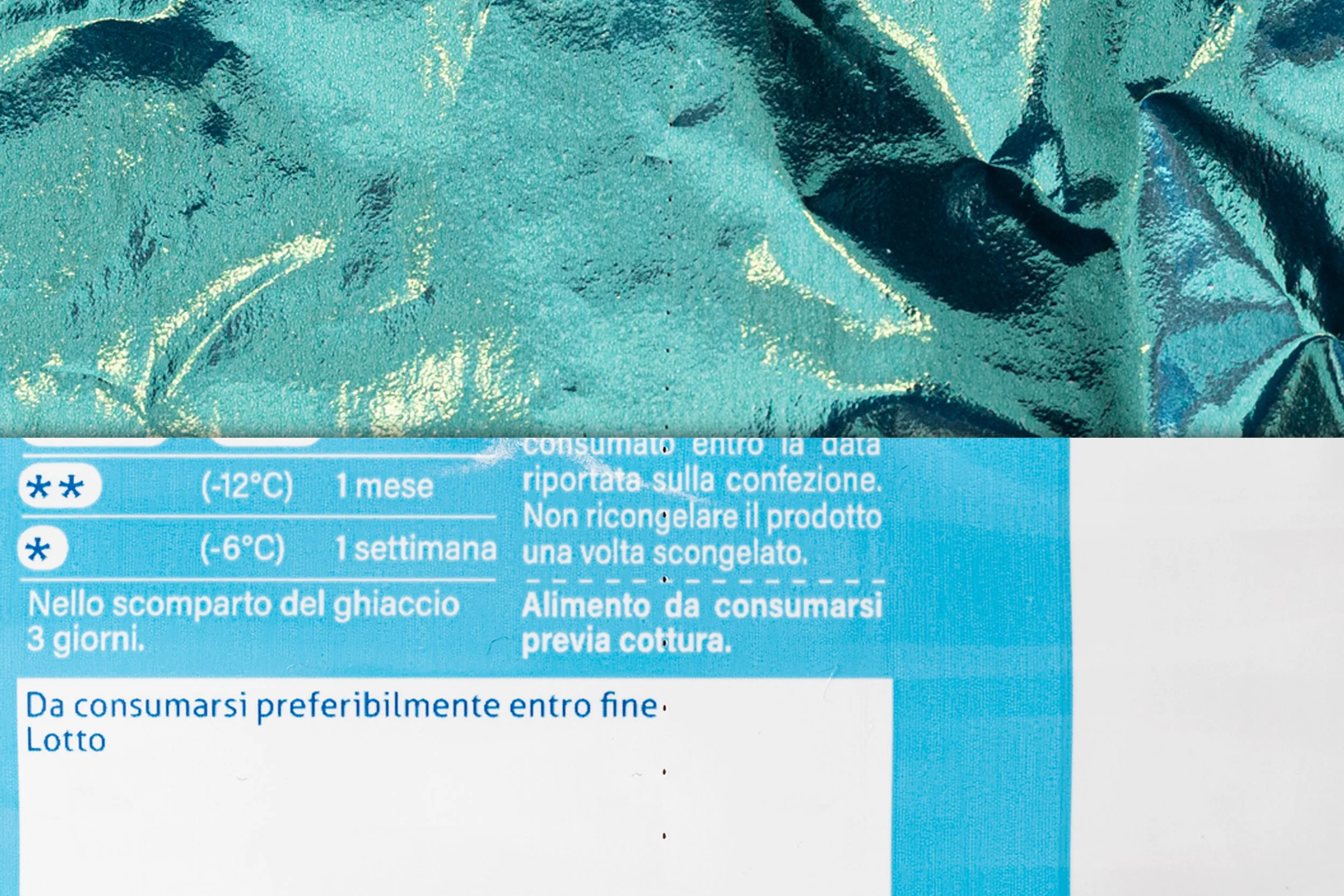

A short introduction: What is Laser Micro Perforation?

Laser microperforation is a process that uses a focused laser beam (typically CO₂-based) to create very small holes—usually between 40 and 200 microns (µm)—in thin materials like plastic films, paper, or foil.

The laser emits a high-energy infrared beam, which is focused onto the material.

The intense heat vaporizes (sublimates) a tiny area of the surface—without touching it—creating a clean, precise micro-hole.

This process happens very quickly and without mechanical contact, allowing for non-stop, high-speed production.

Main Advantages of Laser Microperforation

✔ No physical contact → no tool wear or deformation

✔ High precision → consistent hole size and placement

✔ Adjustable → hole diameter, spacing, and pattern can be easily changed in software

✔ Clean edges → no tearing or rough edges around the hole

✔ Ideal for MAP (Modified Atmosphere Packaging), breathable films, or easy-open features (via scoring)

Laser vs. Mechanical Perforation – Key Differences

In summary, laser microperforation offers a cleaner, more flexible, and more precise alternative to traditional mechanical methods—especially valuable in packaging, food preservation, and applications requiring controlled airflow or easy-opening.

How Laser Micro Perforation works

Spark Machinery Laser Microperforation Systems – Overview

Spark Machinery’s laser microperforation systems are built for precise, high-speed processing of materials like polymer films, paper, and laminates. Key components include:

Laser Source

Sealed CO₂ laser (10.6 µm) with adjustable power and pulse frequency. Delivers consistent microperforation at high line speeds through stable beam quality.Beam Steering / Scanning Head

Galvanometric mirrors (e.g., LO‑S40) steer the laser dynamically across the web, enabling precise, programmable patterns without mechanical movement.Web Transport & Synchronization

Tension-controlled rollers and optical encoders ensure accurate laser triggering and consistent registration with moving substrates.Control System

PLC with touchscreen HMI for full process control, including laser parameters, hole pitch, pattern logic, and scoring. Supports recipes, diagnostics, and optional Industry 4.0 connectivity.Adjustable Parameters

Hole size: 40–200 µm

Pitch & pattern: Fully programmable

Scoring: Enables easy-open or controlled-tear features via subsurface ablation

Quality Control

Optional vision system monitors hole size, shape, and pitch in real time. Closed-loop feedback allows automatic adjustments to maintain consistent quality and reduce waste.

Advantages of Laser Micro Perforation

-

Laser perforation doesn’t rely on mechanical tools, eliminating wear and reducing downtime.

-

Maintains consistent microperforation even at high web speeds, ideal for fast production environments.

-

Enables flexible perforation designs—linear, staggered, or custom—adaptable via software without hardware changes.

-

Microperforation optimizes gas exchange, helping extend the freshness of packaged products.

-

Modern laser systems are highly efficient and require minimal maintenance compared to mechanical alternatives.

-

Integrated camera systems enable real-time inspection and automatic corrections, ensuring consistent product quality.

Why choose Spark Machinery?

Uncompromising Quality, Reliability & Performance

Spark Machinery designs and builds high-performance systems known for their precision, durability, and consistent output. Our machines operate reliably even under high-speed, high-demand production conditions, delivering top-tier results with minimal downtime.

Tailor-Made Solutions for Every Customer

We don’t believe in one-size-fits-all. Every system is engineered based on the specific needs of our customers—whether it’s material type, production speed, perforation pattern, or integration with existing lines. This ensures optimal efficiency and seamless operation from day one.End-to-End Support

Our commitment goes beyond machine delivery. We offer expert guidance during project planning, hands-on support during installation and training, and responsive service throughout the machine’s operational life. We're your partner before, during, and after purchase.Driven by Research & Innovation

At Spark Machinery, continuous improvement is part of our DNA. We invest heavily in R&D and testing to develop cutting-edge laser technologies, improve system capabilities, and stay ahead of evolving market demands. Innovation is what keeps our customers competitive—and we deliver it with every machine.

Applications of our Laser Micro Perforators

-

Extends shelf life by enabling controlled airflow in fresh produce, bakery, and snack packaging. Supports Modified Atmosphere Packaging (MAP) by regulating gas exchange.

-

Ensures product integrity in sterile blister packs and allows easy-tear access for single-dose sachets and medical pouches.

-

Improves breathability and performance in insulation, acoustic materials, and functional films used in vehicle interiors and engine components.

-

Enhances comfort and breathability in products like diapers and sanitary items. Also supports clean dispensing in wipe packaging.

-

Controls humidity and temperature in greenhouse and mulch films; maintains seed viability through ventilated packaging.

-

Prevents bag swelling in chemical or powder packaging and allows for functional or decorative perforation patterns.

Get expert advice for your Micro Perforation Needs

Choosing the ideal micro-perforating machine can be a complex decision, given the diverse technologies and material considerations involved. To ensure you select the perfect solution for your specific needs, we invite you to a free, no-obligation consultation with our experts. Benefit from personalized insights into how the right hot, cold, or laser perforation technology can optimize your production, enhance product quality, and drive efficiency, ensuring a smart investment tailored to your success.

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

DANA NURTAZINA

Commercial Export Office