Laser Microperforation – Technology, Benefits & Applications

Laser microperforation is a precision technology used to create extremely small, consistent holes in a wide range of materials. By using controlled laser energy, this process allows manufacturers to fine-tune permeability, airflow, or light transmission—capabilities that are invaluable across industries such as food packaging, textiles, and electronics.

In this article, we explore what laser microperforation is, how it works, and the advantages it offers compared to traditional mechanical methods. You’ll also discover the key applications of this technology and learn which materials are best suited for laser perforation.

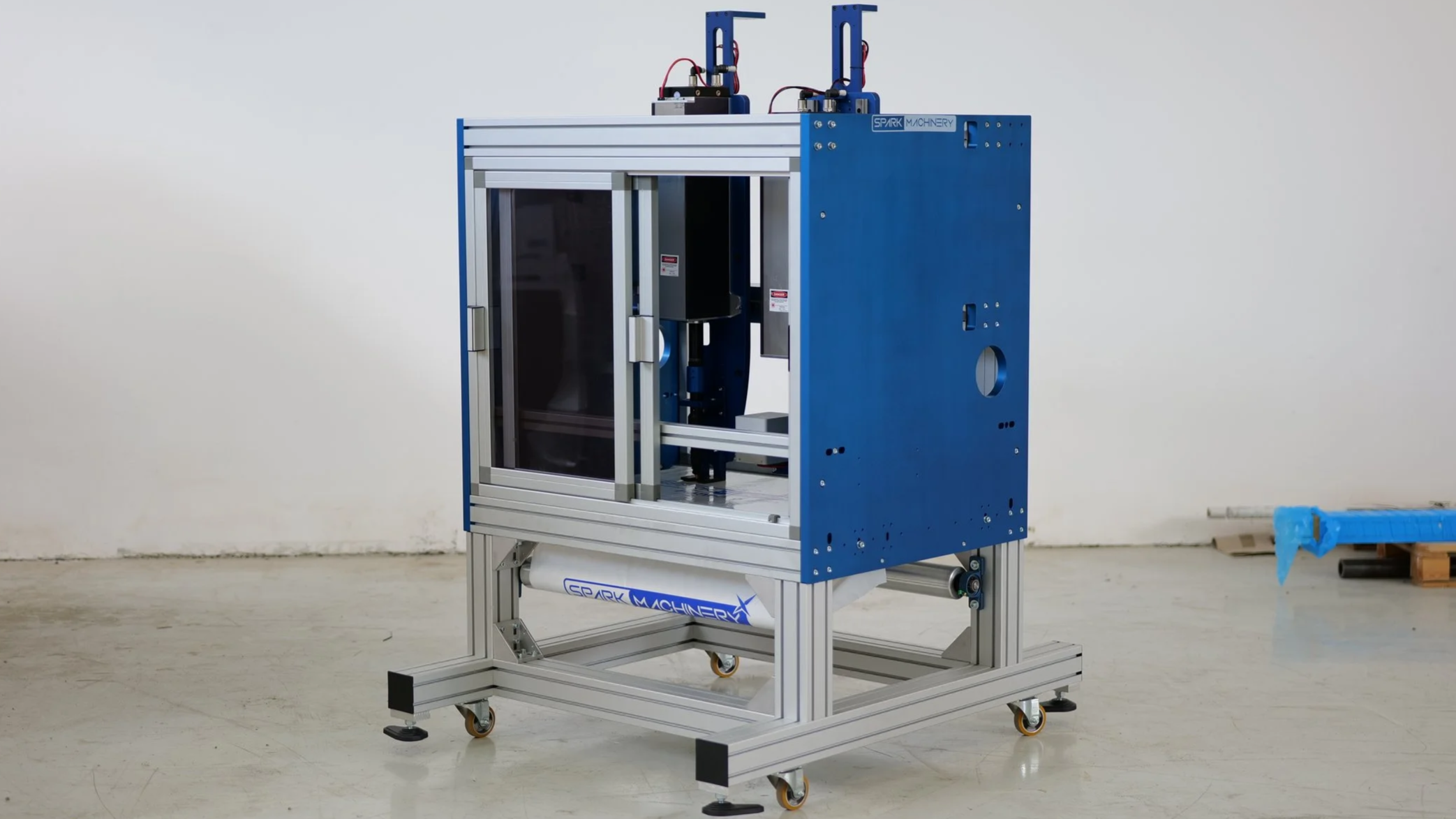

As an experienced manufacturer of high-performance perforation machinery, Spark Machinery brings years of expertise to designing and producing laser systems that deliver precise, reliable, and efficient results. Whether you’re enhancing product performance, optimizing packaging functionality, or exploring new manufacturing possibilities, understanding laser microperforation is the first step toward innovation.

Explore our Laser Perforation Machines!

What is Laser Microperforation?

Laser perforation, also known as laser micro-perforation, is a precise process that uses focused laser beams to create tiny, uniform holes—called nano holes—in different materials. These nano holes can be carefully controlled in size, spacing, and pattern to achieve specific levels of airflow, moisture release, or gas exchange.

This technology plays a key role in packaging and industrial applications, where it helps improve product freshness, breathability, or performance. By using laser energy instead of mechanical tools, laser micro-perforation ensures clean, consistent results without damaging the surrounding material.

Let’s get technical: How does Laser Microperforation work?

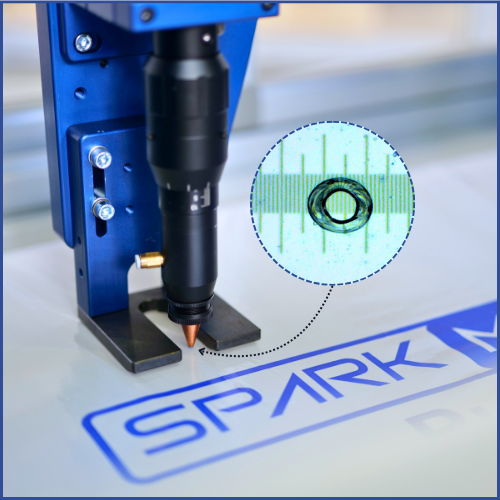

Laser perforation technology enables the creation of micro- and nano-sized holes in flexible packaging films with high accuracy and repeatability. Using focused laser energy—typically from CO₂ sources—Spark Machinery’s laser perforators can produce controlled perforations that regulate gas and moisture transmission through the film. The result is a clean, efficient, and reliable process that supports both performance and sustainability in modern packaging production.

From a technical standpoint, CO₂ lasers are preferred for their ability to generate clean, circular holes without mechanical stress on the film. Systems can include one to eight laser sources, each around 350 W (up to 1500W), operating at web speeds up to 400 m/min. The result is a process that combines high throughput with micrometric precision.

Laser perforation systems are compatible with various substrates, including mono-materials, laminates, paper-based films, and even recycled or recyclable plastics. Hole diameters typically fall between 40 µm and 200 µm and advanced process control involves precise adjustment of pulse frequency, energy, and spot diameter. When integrated with camera-based monitoring systems, the process gains real-time feedback on hole quality, diameter, and spacing. This visual inspection ensures every perforation meets defined specifications, enabling automatic correction and quality assurance during high-speed production.

Different types of Laser Microperforation

Laser perforation can be achieved using two main approaches: focus laser perforation and scanning laser perforation. Both methods rely on the precision and controllability of laser energy but differ in how the beam interacts with the moving film.

-

In focus laser perforation, the laser beam is fixed in position and tightly focused on a specific point of the material. The perforation is formed as the film moves continuously under the stationary beam. This method allows excellent control of hole size and depth, as the focused spot maintains consistent energy density. It is ideal for applications requiring linear, uniform perforation lines with precise spacing. The technique is mechanically simple and highly reliable at medium to high web speeds.

-

Scanning laser perforation, on the other hand, uses a galvanometric mirror system to rapidly move—or “scan”—the laser beam across the film surface. Instead of keeping the beam static, the scanner deflects it in controlled patterns, allowing perforations to be placed at variable positions, shapes, or densities within a single web. This flexibility is valuable when producing localized perforation zones or complex patterns. Scanning systems can operate at higher speeds and can dynamically adjust perforation parameters during production.

The main difference lies in flexibility and control. Focus perforation excels in producing continuous, high-precision lines with minimal optical complexity, while scanning perforation offers superior versatility for customized layouts and adaptive processing. In modern machinery, both methods can be combined—using fixed-beam lasers for longitudinal lines and scanning heads for variable perforation areas—to deliver maximum performance and design freedom in flexible packaging applications.

Benefits of Laser Microperforation

Extremely small hole size achievable

Laser systems can produce micro- and nano-scale holes, enabling precise control of gas and moisture transmission in flexible films.Consistent quality and repeatability

Computer-controlled parameters ensure every perforation is identical in size, shape, and spacing, maintaining uniform performance across high-speed production runs.No mechanical wear and tear

Because the process is completely non-contact, there are no physical tools or needles to dull, wear out, or contaminate the material, resulting in lower maintenance and longer system life.Eco-friendly process

Laser perforation requires no consumables, chemicals, or mechanical punching tools. It generates minimal waste and reduces the environmental footprint compared to traditional perforation methods.High production efficiency and precision

Advanced CO₂ laser systems operate at very high web speeds, combining high throughput with micrometric accuracy. Parameters such as pulse energy, frequency, and focus can be finely tuned for optimal results.Integration into automated packaging lines

Laser perforation units can be seamlessly integrated into existing slitting, winding, or packaging lines. Real-time monitoring and control systems allow automatic adjustments, ensuring process stability and consistent quality in fully automated production environments.

Applications of Laser Microperforation

Laser perforation delivers precision, cleanliness, and versatility across key manufacturing sectors. Its non-contact process creates micrometric holes with high repeatability—essential for performance, efficiency, and scalability in B2B production environments.

-

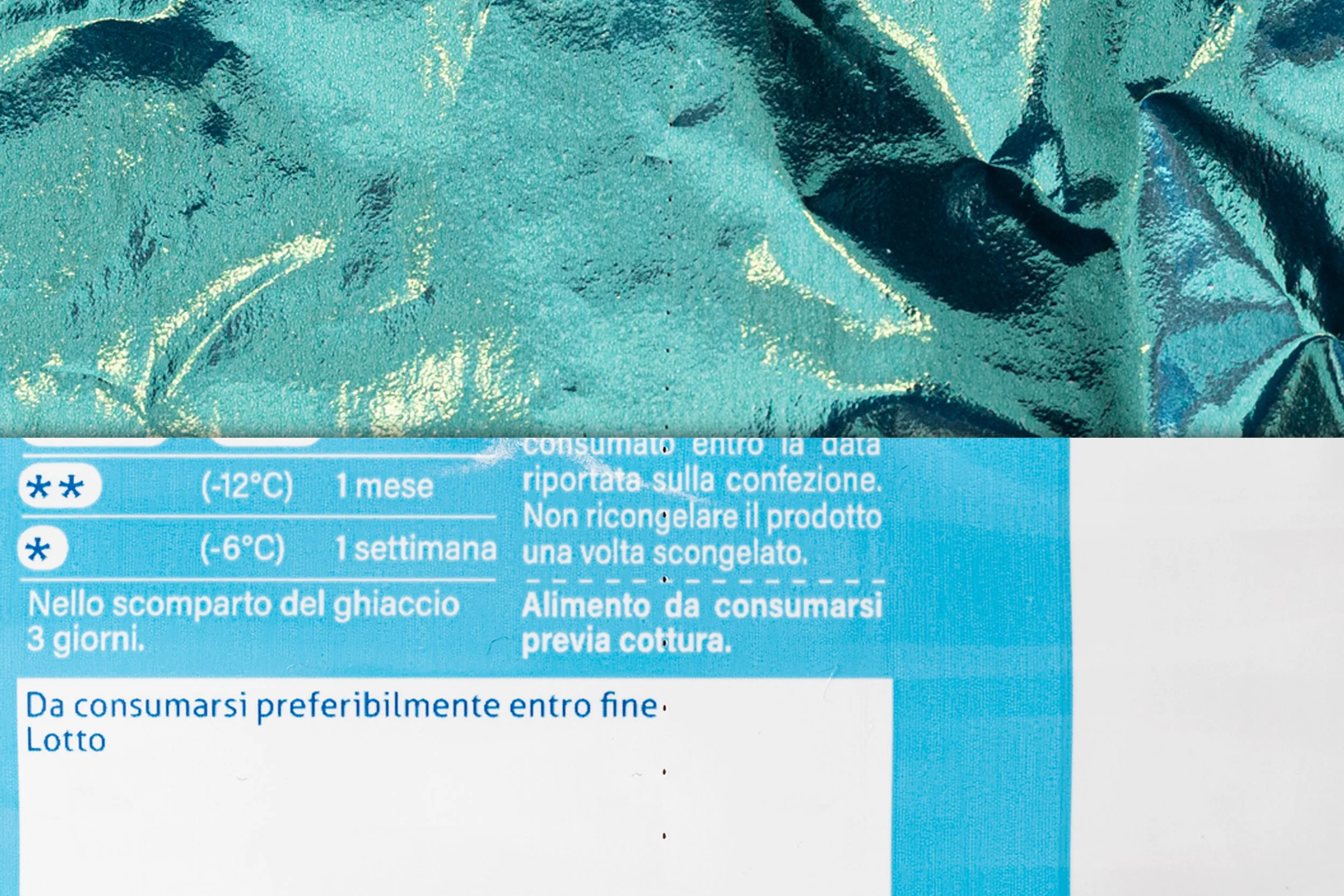

In flexible packaging, laser perforation enables Modified Atmosphere Packaging (MAP) and breathable films that extend the freshness of produce and baked goods. It also supports easy-open features through controlled microperforation or laser scoring, improving consumer convenience while maintaining barrier integrity. For converters, it offers fast setup, minimal waste, and compatibility with automated packaging lines.

-

The technology provides controlled microperforations for medical devices, sterile packaging, and diagnostic strips, ensuring airflow or gas exchange where needed. Its clean, non-contact process eliminates contamination risks and meets the high precision standards required in medical manufacturing.

-

In technical and automotive sectors, laser perforation is used for membranes, filters, and ventilation systems, producing uniform holes that enhance airflow and durability. It’s also applied to technical textiles and composites, where consistency and mechanical strength are critical. Additionally, laser perforation is increasingly used for aesthetic purposes—such as decorative patterns on interior materials, acoustic panels, and design elements—combining functional performance with visual appeal.

What materials can be perforated with a Laser System?

Laser perforation systems are highly versatile and can process a wide range of materials used across packaging, medical, and industrial applications. The non-contact nature of the laser allows for clean, precise perforations without mechanical stress or deformation. Below are the main material groups suitable for laser perforation:

-

Widely used in food packaging and industrial applications, plastic films are ideal for laser perforation. CO₂ lasers can create micro-holes that regulate gas or moisture transmission. The process can be tailored for different film thicknesses and optical properties to maintain strength and barrier performance.

-

Paper substrates benefit from laser perforation for breathable and easy-open packaging solutions. The laser can create micro-holes or scoring lines without tearing or compromising structural integrity, offering a sustainable alternative for compostable or recyclable packaging.

-

Thin foils, including aluminum or metallized films, can be perforated with precise control of energy and pulse duration. This is essential for applications like controlled venting, sensor membranes, or decorative finishes, where hole size and placement accuracy are critical.

-

Multi-layer materials—such as PET/PE or paper/plastic laminates—can be selectively perforated through one or multiple layers. Laser parameters are adjusted to control penetration depth, ensuring functionality without delamination or barrier loss.

Need expert advice on Laser Microperforation?

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

DANA NURTAZINA

Commercial Export Office