Micro Perforation

Precise Perforation for Industrial Applications

What is Micro Perforation and how does it work?

What does microperforated mean?

Microperforation in industrial packaging involves making tiny, precise holes (tens to hundreds of microns) in packaging materials like films. These microscopic perforations allow for controlled air and moisture exchange, which is crucial for various products. It helps extend the shelf-life of fresh goods, prevents condensation, or allows for steam release in microwaveable items, all while keeping the package sealed and protective.

How does Micro Perforation works?

Microperforation is a vital process in industrial packaging, creating extremely small, precisely sized holes in flexible materials. The goal is to engineer specific permeability, allowing controlled gas exchange for benefits like extended shelf-life or steam venting.

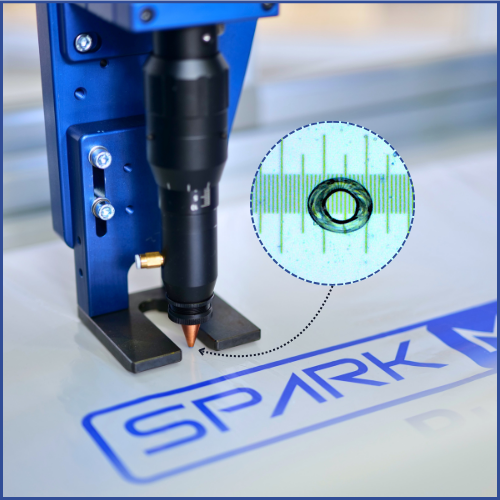

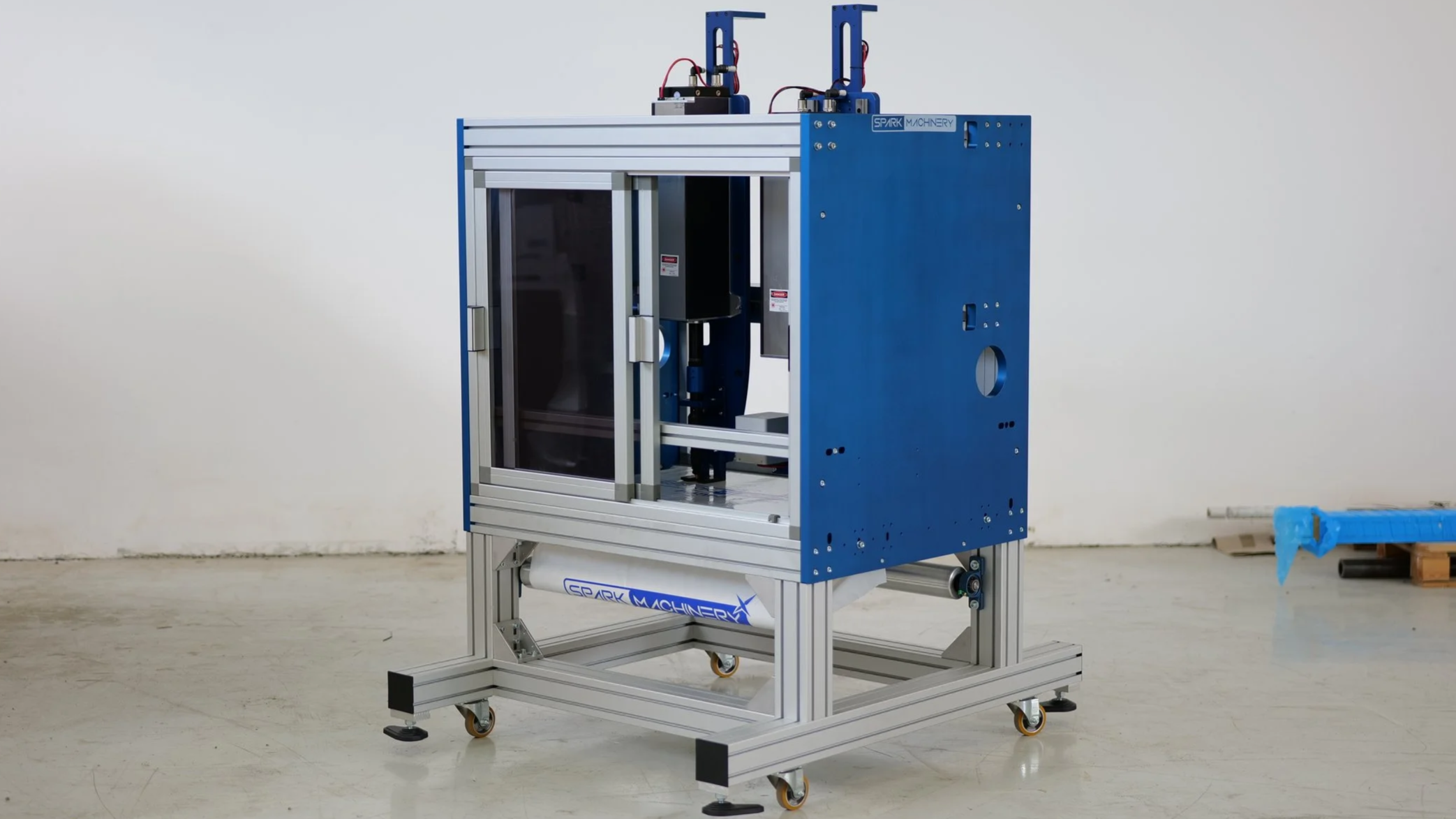

Laser Microperforation

Technical Process: This method uses highly focused CO2 lasers to vaporize the material, creating holes typically ranging from tens to hundreds of microns (e.g., 40-200 µm). Sophisticated scanning systems direct the laser beam, allowing for rapid and precise hole creation. Laser parameters are meticulously controlled by software to achieve desired hole size, shape, and pattern. It's a non-contact process, meaning no physical tool touches the material.

Precision and Repeatability: Laser microperforation offers unparalleled precision and repeatability. Being software-controlled and non-contact, there's no tool wear affecting quality over time. Hole diameter, spacing, and pattern are precisely controlled, crucial for consistent performance in applications like Modified Atmosphere Packaging (MAP). Patterns or hole sizes can be instantly adjusted via software.

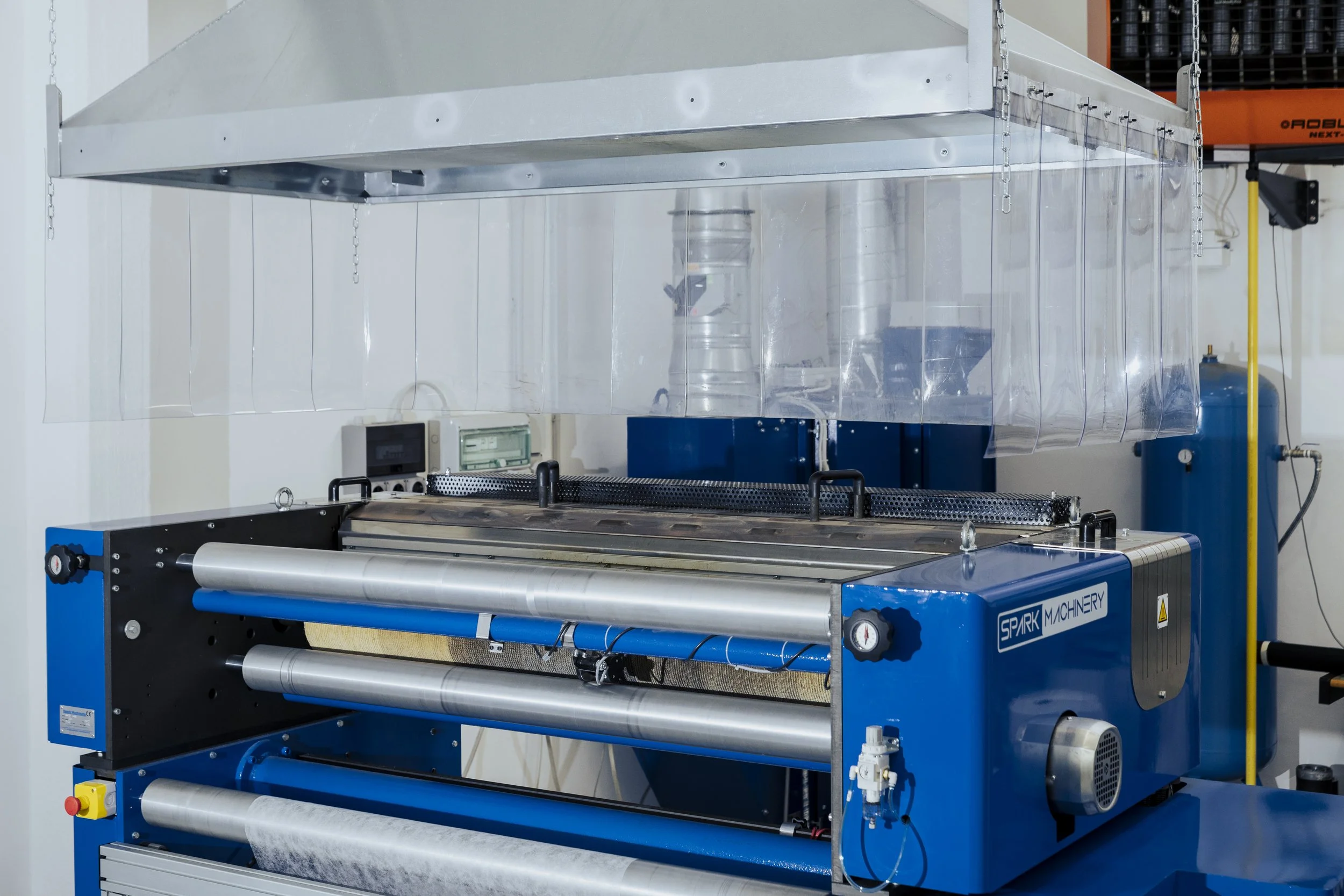

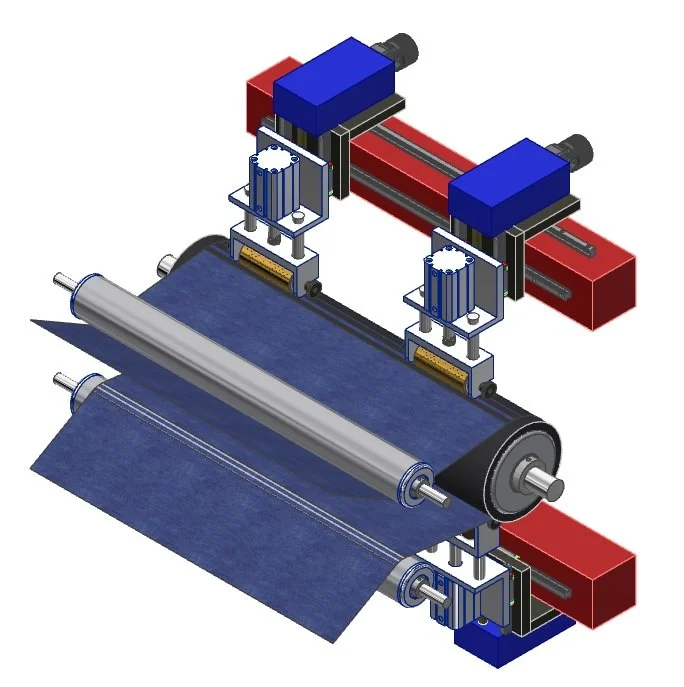

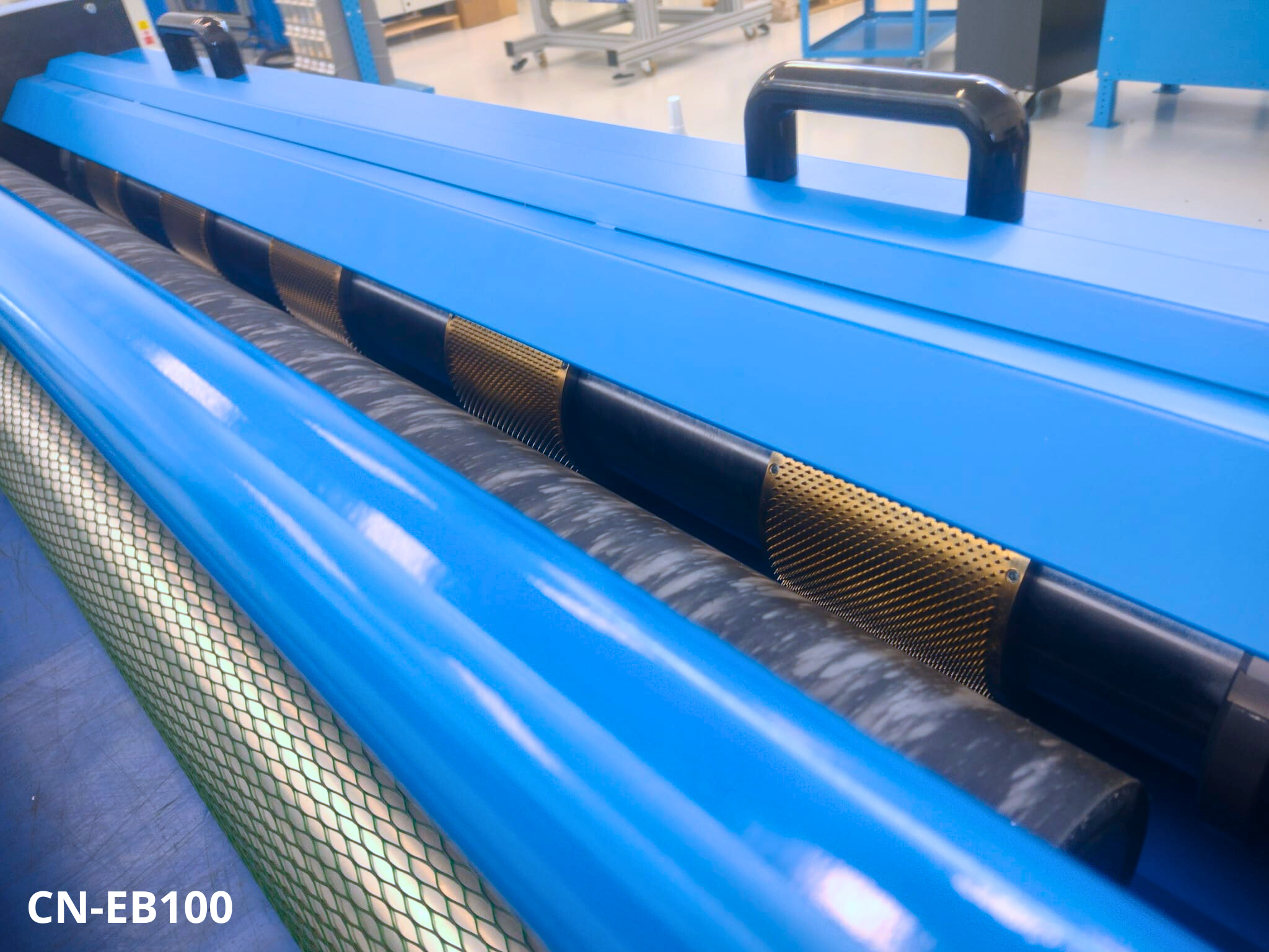

Mechanical Microperforation

Technical Process: Mechanical methods physically puncture the material. Needle rollers are common, using rotating cylinders embedded with fine needles to pierce the film. Needles can be heated ("hot needle perforation") for cleaner holes with some material melt-back, or used cold ("cold needle perforation").

Precision and Repeatability: Mechanical methods generally offer lower precision compared to laser for very small micro-holes. The minimum hole size is limited by the physical dimensions of the needles. While suitable for many applications and efficient for high densities of larger micro-holes, achieving the extremely fine and consistent perforations needed for demanding MAP scenarios can be challenging.

Suitable materials for Micro Perforation

-

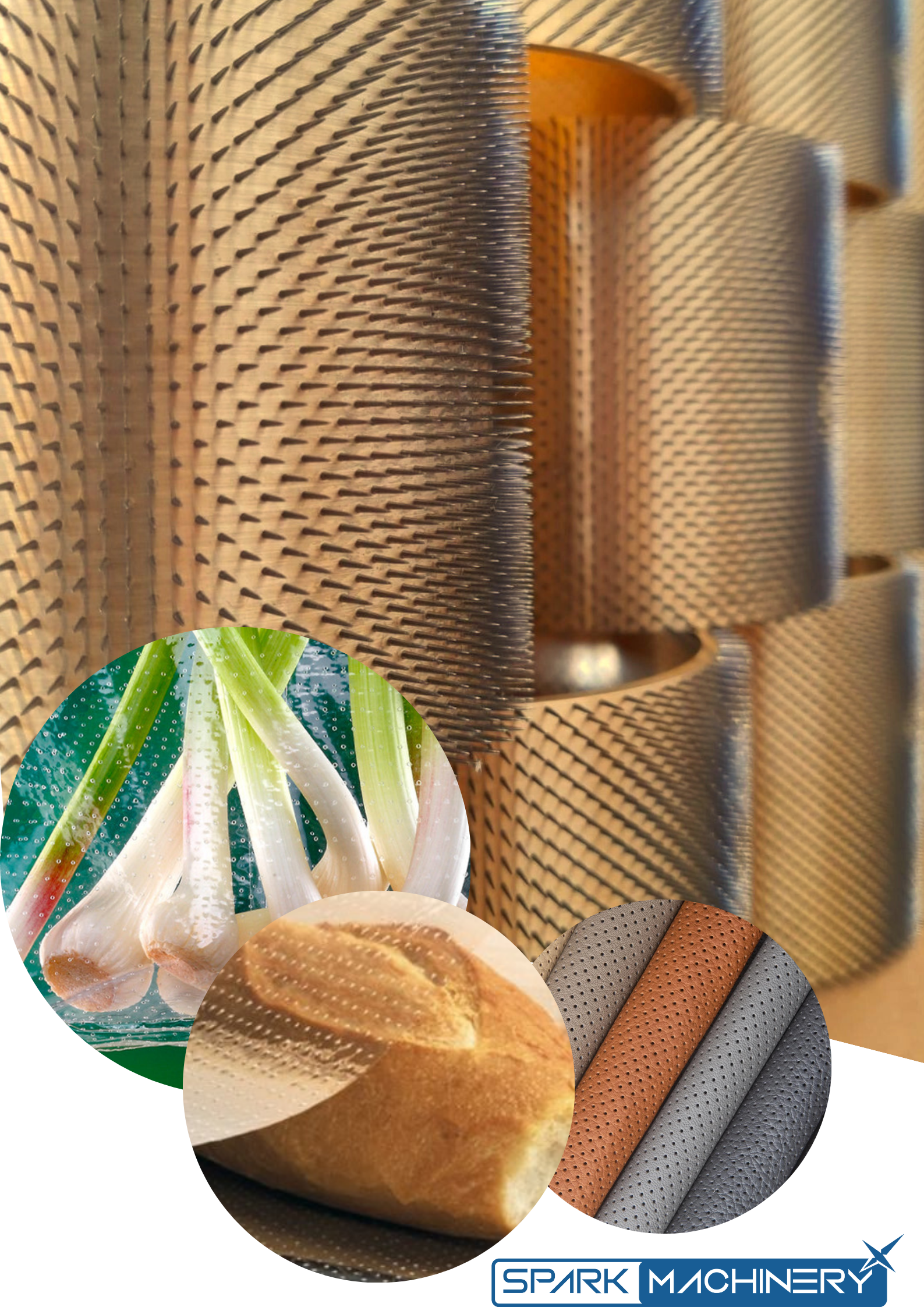

This is the most common category for microperforation, including films like Polyethylene (PE), Polypropylene (PP, including BOPP), Polyethylene Terephthalate (PET), and Polyamide (PA). These are crucial for Modified Atmosphere Packaging (MAP) of fresh produce, where precise gas exchange extends shelf-life. They're also used in microwaveable packaging for steam venting. Both laser and needle perforation are used, with laser offering superior precision for very fine, consistent holes vital for specific gas transmission rates.

-

Lightweight paper materials are gaining popularity in sustainable packaging solutions. Microperforation enhances product freshness by allowing breathability—ideal for baked goods, fresh produce, and more. It also enables easy-open features that improve user convenience. Laser technology ensures clean, precise perforations without tearing, delivering both performance and a premium packaging experience.

-

These are multi-layer materials combining different substances (e.g., plastic films, film with foil, film with paper) to leverage diverse properties like barrier and strength. Microperforation is essential when controlled permeability is needed through these complex structures, common in sophisticated food packaging. Laser microperforation is often preferred due to its ability to precisely penetrate multiple layers with minimal thermal impact.

-

Thin metallic sheets, primarily aluminum foil, offer excellent barriers against light, moisture, and gases. Microperforation introduces controlled permeability into this otherwise impermeable material, used for microwaveable applications (e.g., steam venting in ready meals with foil lids) or for specific products requiring minimal, controlled gas exchange. Laser microperforation is typically the preferred method for foils due to the precision required.

-

Increasingly, microperforation is being applied to monomaterial packaging solutions. These consist of a single type of polymer (e.g., all PE or all PP), making them easier to recycle compared to multi-material laminates. Microperforation helps these sustainable alternatives achieve the necessary permeability for products like fresh produce while maintaining their recyclability, contributing to a more circular economy in packaging

Microperforation can be applied to a wide range of packaging materials, with suitability often depending on the chosen perforation method (laser vs. mechanical) and the desired functional benefits.

Benefits of Micro Perforation

Here are the key benefits:

Extended Shelf Life: This is a primary advantage, particularly for fresh food products like fruits, vegetables, and baked goods. By creating precise, tiny holes, microperforation enables Modified Atmosphere Packaging (MAP), allowing for controlled gas exchange (e.g., oxygen, carbon dioxide, and water vapor). This regulates the respiration rate of fresh produce, significantly slowing down spoilage and thus extending the product's freshness and usability.

Improved Breathability and Condensation Control: For products that emit moisture or require air circulation, microperforation provides essential breathability. This prevents the build-up of condensation inside the package, which can lead to sogginess, mold growth, or obscure the product's view, maintaining optimal product quality and visual appeal.

Controlled Tear Lines and Easy Opening: Microperforation can be strategically used to create weakened lines on packaging films or papers. These "perforated tear lines" allow consumers to easily and neatly open packages without needing scissors, enhancing user convenience and improving the overall unboxing experience.

Micro Perforation vs. Macro Perforation

Enhanced Product Protection and Presentation: While allowing gas exchange, microperforation maintains the overall integrity and protective qualities of the packaging. It can prevent package "ballooning" or "collapsing" due to gas build-up or evacuation. Furthermore, by preventing condensation and maintaining product freshness, it significantly improves the visual presentation of the product on the shelf, making it more appealing to consumers.

These multifaceted benefits translate directly into added value for manufacturers, retailers, and consumers. For manufacturers, extended shelf life reduces waste, broadens distribution capabilities, and can open new markets. For retailers, fresher products lead to fewer discards and higher customer satisfaction. For consumers, the convenience of easy-open packaging and the assurance of fresher, better-preserved products enhance their overall experience, fostering brand loyalty and driving repeat purchases.

Micro and macro perforation are both techniques used to create holes in packaging materials, but they differ significantly in scale, impact on material, and application. The choice between them depends entirely on the specific functional requirements of the package.

Here's a comparison table:

| FEATURE | MICRO PERFORATION | MACRO PERFORATION |

|---|---|---|

| Hole Size (Diameter) | Typically tens to a few hundreds of microns (e.g., 40 µm to 500 µm). | Typically millimeters (e.g., 1 mm to 100 mm). |

| Machine Types | Primarily Laser Perforators (CO2 lasers) for high precision. Also Hot/Cold Needle Rollers for specific applications. | Primarily Mechanical Systems like Needle Rollers (with larger needles) or Punching/Die systems. |

| Hole Density | Can achieve very high densities, often imperceptible to the naked eye. | Lower density of holes, as they are much larger and more visible. |

| Impact on Barrier | Minimal impact on overall barrier properties beyond the controlled gas exchange. Designed to maintain structural integrity. | Can significantly reduce barrier properties due to larger, more open holes. |

| Typical Use Cases | - Modified Atmosphere Packaging (MAP) for fresh produce (fruits, vegetables, salads) to control respiration and extend shelf-life. - Microwaveable packaging for controlled steam venting (e.g., ready meals). - Condensation control in packaged goods. - Breathable packaging for baked goods. - Tamper-evident seals requiring clean separation (e.g., bottle caps, coupons). | - Bulk packaging for aeration of products (e.g., large bags of potatoes, onions). - Easy drainage for products packed with excess moisture (e.g., some fresh-cut flowers). - Handles or hanging holes on bags. - Tear-off sections on larger bags or promotional materials where precise tearing isn't critical but opening is needed. - Hole punching for mulching |

Areas of application in Micro Perforation

-

Microperforation, the art of creating microscopic, precise holes in various materials, is a cornerstone technology for modern industrial packaging. At Spark Machinery, we leverage cutting-edge laser and mechanical systems to deliver solutions that optimize product integrity, shelf-life, and consumer convenience across diverse sectors.

-

The most prominent application of microperforation is in food packaging, especially for fresh produce. By enabling Modified Atmosphere Packaging (MAP), micro-perforated films regulate gas exchange, significantly extending shelf life and reducing spoilage. It's also critical for microwaveable packaging, safely venting steam during cooking to ensure optimal results and consumer safety.

-

In the medical field, microperforation is vital for sterile barrier systems for devices and disposables. It allows for gas sterilization (e.g., ethylene oxide) while maintaining a microbial barrier, ensuring product sterility until use, crucial for patient safety.

-

For a wide array of consumer goods, microperforation enhances convenience. Precisely placed micro-perforated lines allow for controlled tear propagation, making packages easy to open cleanly without scissors, improving the overall consumer experience.

-

Beyond consumer-facing applications, microperforation provides critical functionality in industrial films and labels, used for venting trapped air or creating tamper-evident features. In the automotive sector, it's utilized in components like acoustical materials for sound absorption, enabling controlled airflow for noise reduction in vehicle interiors. It also finds use in filtration media and in certain interior trim components for material breathability.

At Spark Machinery, our expertise in microperforation enables these diverse functionalities, helping our clients achieve superior product performance and market success

Need expert advice on Micro Perforation?

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

FEDERICA CANTAGALLI

Commercial Export Office