Embossing Machines by Spark Machinery

Our Embossing Machine Models

What Are Embossing Machines?

At Spark Machinery, our embossing systems are designed to bring precision, consistency, and creativity to surface structuring. These machines imprint fine or deep patterns onto films, foils, laminates, or other sheet materials — shaping texture, appearance, and function in a single pass.

How It Works

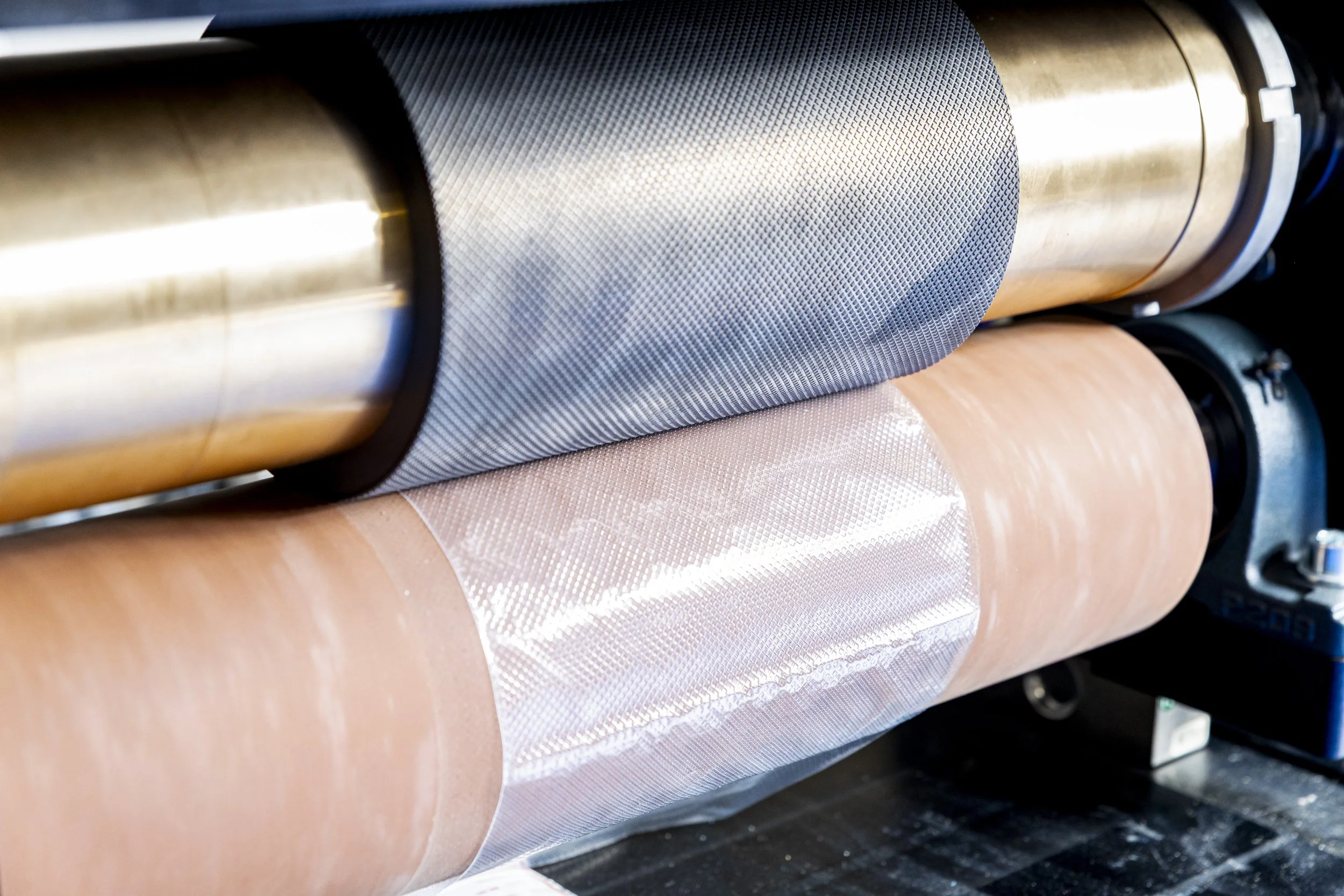

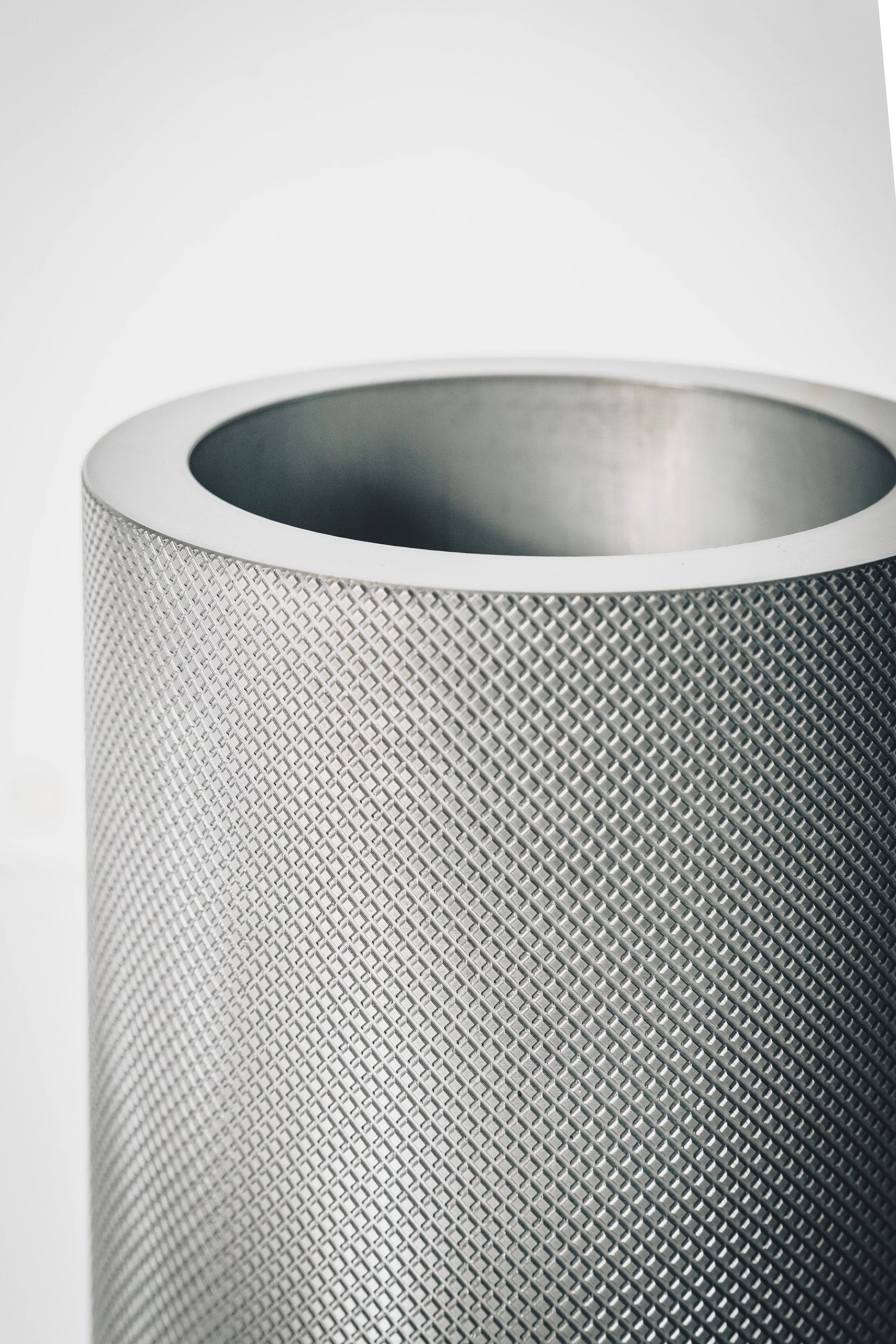

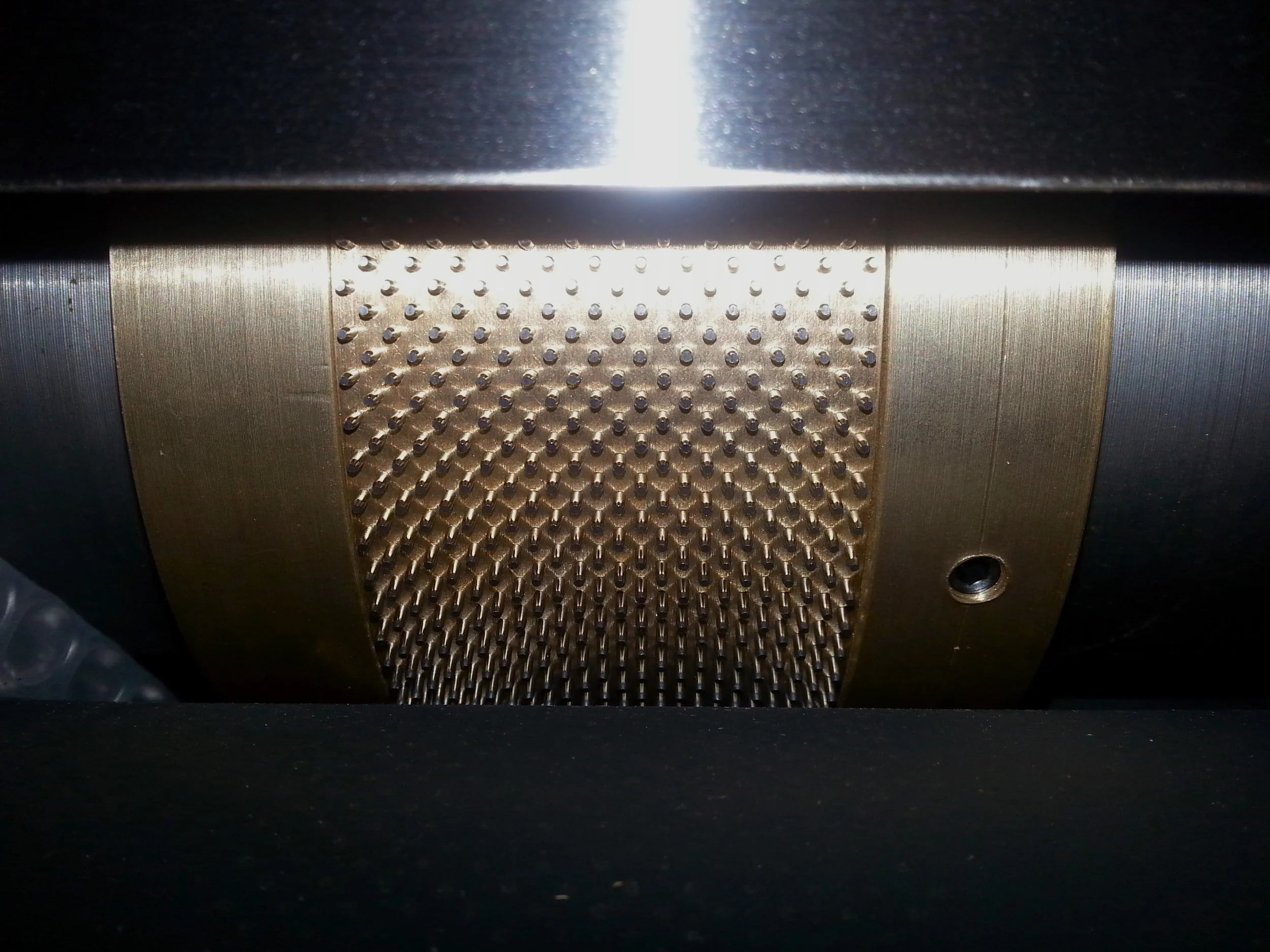

Embossing is achieved by pressing the material between a patterned embossing roll and a counter roll. Through the controlled application of pressure and pattern geometry, the surface of the material is permanently reshaped, producing raised or recessed features that define its final look and performance.

Embossing systems are widely used in the production of technical films, pharmaceutical and food packaging, construction materials, and many other industrial applications. Thanks to their versatility and consistent performance, Spark Machinery’s embossing machines enhance both the aesthetic and functional properties of film-based materials.

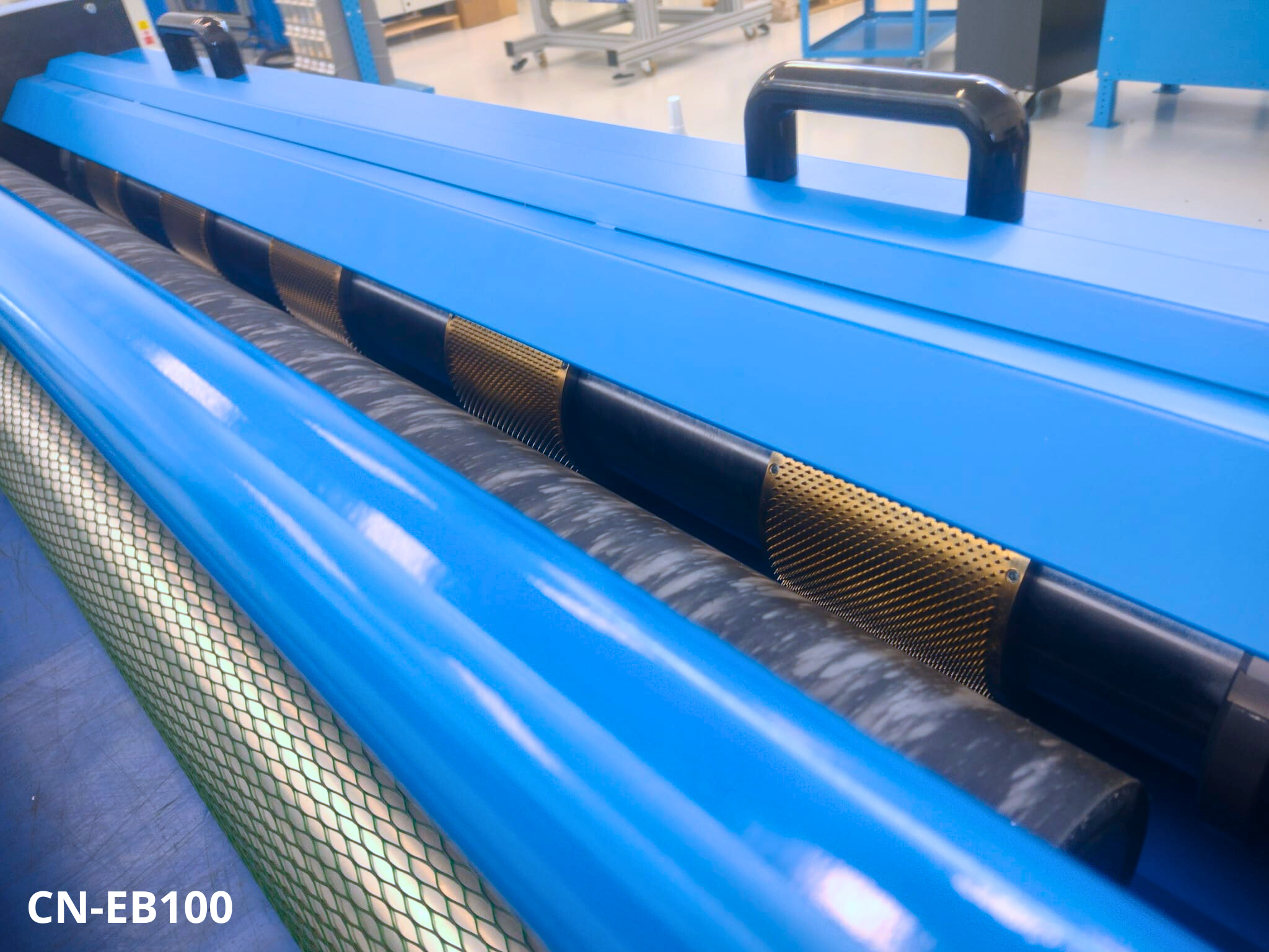

Model CN-EB Embossing Machine with Customizable Cylinders for Moving Film

Embossing Machine Models – CNEB and CNEBM

Spark Machinery offers two models of compact embossing units designed for integration into continuous film processing lines:

CNEB: Non-motorized version, driven by the host machine.

CNEBM: Motorized version, equipped with an independent drive system for speed synchronization and process control.

Both models are versatile, space-efficient systems engineered to emboss a wide range of film types, diameters, and surface geometries. They are designed to operate inline with slitters, extruders, printing units, welding machines, and other converting or packaging equipment handling continuous web materials.

These units enable the precise surface structuring of films and foils for diverse applications, including:

Functional texturing: Anti-slip, anti-block, or controlled-friction surfaces.

Decorative embossing: Custom patterns, tactile finishes, and aesthetic enhancements.

Technical applications: Embossed films for hygienic, industrial, pharmaceutical, and food packaging sectors, as well as construction materials.

Each machine is built for high mechanical stability, accurate pattern transfer, and seamless integration within modern film production lines, ensuring consistent surface quality and reliable operation across a wide range of materials.

| TECHNICAL DATA SHEET | |

|---|---|

| Description | "Cold" embossing machine for moving film |

| Ø NEEDLE SHAFT | 60mm - 100mm - 200mm |

| CNEB MOVEMENT | Movement by film dragging |

| CNEBM MOVEMENT | Movement by asynchronous motor 400 V+N+T - 50 Hz |

| PENETRATION ADJUSTMENT | Micrometric screws with graduated knobs |

| MAX. SPEED | 300* meters/minute |

| SUPPORT ROLLER APPROACH MOVEMENT | Pneumatic movement |

| AIR PRESSURE | 6 BAR |

| * | Value dependent on the type of material processed |

For more detailed information click the link below

How Our Embossing Machines work

Embossing Process – Step-by-Step

Web handling and prep

The film or foil moves through the production line under controlled tension and alignment, ensuring a stable and uniform web as it enters the embossing unit (in this case either the non-motorized CNEB or motorized CNEBM).Tooling setup and nip formation

The embossing group (an embossing cylinder shaft) and the counter roller are positioned so the material will pass between them. On the CNEB motorless model the web motion drives the embossing cylinder; on the CNEBM the cylinder is driven by an asynchronous motor.Roller approach and penetration adjustment

A pneumatic system brings the counter roller into contact with the embossing cylinder to engage the tooling. The depth of embossing (penetration of needles or pattern elements) is adjusted via two micrometric screws for precise control.Embossing execution

As the web passes between the patterned embossing cylinder and the counter roller, the surface is displaced to create raised or recessed features. The CNEB model is driven by the film movement; the CNEBM includes an encoder and motorised drive to match line speed.Down-web handling and stabilization

After embossing, the film is guided via idler rollers or steel support rollers, as needed, to maintain the pattern integrity and ensure smooth downstream processing (e.g., lamination, printing, slitting).Monitoring and adjustment

Throughout the run, variables like web speed, roller contact pressure, penetration depth and web tension are monitored. Any deviation triggers adjustment via the micrometric screws or pneumatic system to maintain consistent embossing quality.Maintenance and tooling care

Regular inspection of the embossing cylinder, needle assemblies, counter roller surface (which may be rubber or bristles depending on material) and bearings ensures reliable repeatability across production runs.

Advantages of Our Embossing Machines

Key Benefits

-

Engineered for perfect control, our embossing machines deliver consistent surface patterns with micrometric accuracy. Uniform pressure and stable mechanics ensure flawless results across every run.

-

Compact and easy to integrate, CNEB and CNEBM units fit seamlessly into slitting, extrusion, or printing lines. Fast setup, quick adjustments, and synchronized operation keep your production moving without interruptions.

-

Inline embossing streamlines your process—no separate finishing steps required. Durable components and low-maintenance design reduce downtime and operating costs, while minimizing material waste.

-

From hygienic and industrial films to pharmaceutical, food, and construction packaging, Spark Machinery embossing machines adapt to your production needs. Custom roller patterns let you create textures, logos, or technical surfaces with precision.

-

Enhance surface functionality without altering film thickness or adding coatings. Achieve anti-slip, anti-block, and improved tactile properties that boost downstream performance in sealing, lamination, and winding.

Why choose Spark Machinery?

Uncompromising Quality, Reliability & Performance

Spark Machinery designs and builds high-performance systems known for their precision, durability, and consistent output. Our machines operate reliably even under high-speed, high-demand production conditions, delivering top-tier results with minimal downtime.Tailor-Made Solutions for Every Customer

We don’t believe in one-size-fits-all. Every system is engineered based on the specific needs of our customers—whether it’s material type, production speed, perforation pattern, or integration with existing lines. This ensures optimal efficiency and seamless operation from day one.End-to-End Support

Our commitment goes beyond machine delivery. We offer expert guidance during project planning, hands-on support during installation and training, and responsive service throughout the machine’s operational life. We're your partner before, during, and after purchase.Driven by Research & Innovation

At Spark Machinery, continuous improvement is part of our DNA. We invest heavily in R&D and testing to develop cutting-edge perforation technologies, improve system capabilities, and stay ahead of evolving market demands. Innovation is what keeps our customers competitive—and we deliver it with every machine.

Areas of Application

-

In the packaging industry, embossing enhances both functionality and appearance. Spark Machinery’s embossing units create textures that improve grip, sealability, and shelf appeal on flexible packaging films used for snacks, personal care, and consumer goods.

Example: anti-slip embossed polyethylene films for automated packing lines, or textured laminates that prevent blocking during roll storage. -

For blister packs and medical laminates, embossing ensures precise texture control for improved formability, product protection, and identification. Patterns can also be used to mark zones or logos without ink contact.

Example: embossed PVC or PVdC blister films that enhance clarity and prevent adhesion during thermoforming. -

In food-grade films and foils, embossing improves handling and product differentiation. It helps reduce air entrapment during sealing and adds decorative or tactile effects for brand distinction.

Example: aluminum foils embossed with fine patterns for chocolate wrapping, or embossed PET films used in vacuum-sealed packaging. -

Embossing adds performance to technical films used in hygiene, filtration, and manufacturing. It controls friction, improves bonding, and regulates airflow or liquid dispersion between layers.

Example: micro-embossed nonwovens in hygiene products, or PE films with controlled texture for release liners and laminates. -

For construction films and membranes, embossing strengthens surface grip, aids layer separation, and improves mechanical stability during installation.

Example: embossed vapor barriers or underlay films that prevent slipping and facilitate handling on construction sites.

Talk to our experts – We’ll guide you to the right solution

Choosing the ideal embossing machine can be a complex decision, given the diverse technologies and material considerations involved. To ensure you select the perfect solution for your specific needs, we invite you to a free, no-obligation consultation with our experts. Benefit from personalized insights into how the right converting machine can optimize your production, enhance product quality, and drive efficiency, ensuring a smart investment tailored to your success.

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

FEDERICA CANTAGALLI

Commercial Export Office