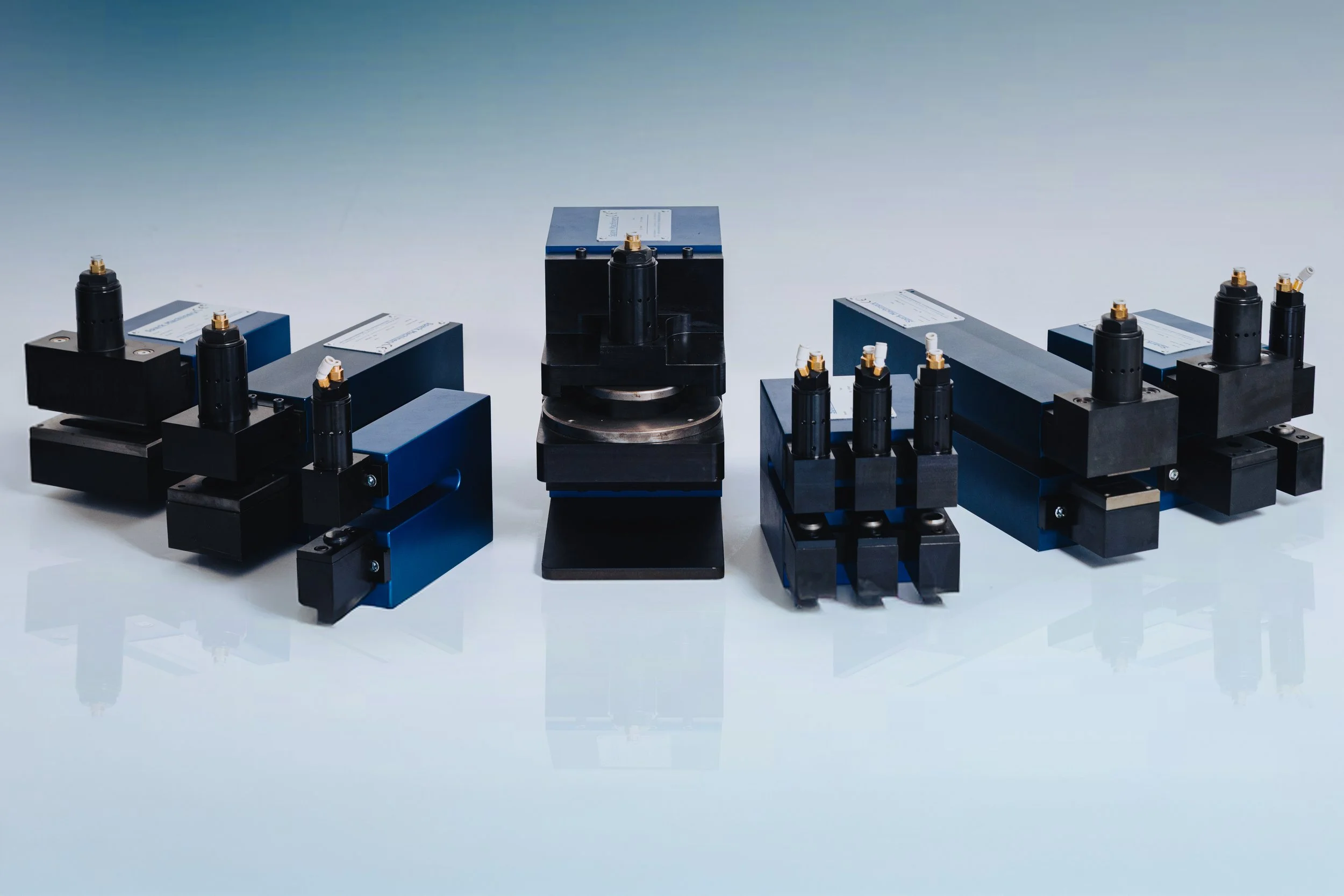

Macro Perforation Machines by Spark Machinery

-

Macro perforation systems are built to punch holes of varying diameters and shapes through flexible materials in motion. These holes confer crucial functional properties—such as permeability, drainage, and controlled airflow—so that films, foils, or nonwoven webs can breathe, release moisture, or equalize pressure without compromising structural integrity. Particularly in packaging, food, agricultural, and industrial contexts, the controlled apertures help maintain product quality, reduce waste, and enhance usability.

-

The versatility of Spark’ Machinery’s macro perforators finds use across numerous industries. In food and produce packaging, macro holes help maintain freshness by allowing gas exchange. In agricultural films and mulching, they support moisture control and plant health. In the manufacture of bags, pouches, and packaging films, they are used for handles, valve holes, euro-slots, or other shaped openings. Because the machines can process a wide range of flexible substrates (PE, PP, BOPP, nonwovens, even composite films), they serve clients ranging from packaging converters to agricultural product manufacturers.

-

Spark Machinery offers side-unit and bridge (PU series) designs that integrate directly into moving film lines. The bridge systems are engineered for high speed and stability—operating at up to 250 m/min under optimal conditions. Side units arecompact and ideal for punching along film edges, making them easy to integrate into existing lines. The actual perforation is achieved via punch-and-die mechanisms — pneumatically actuated — with a choice of dies to produce circles, euro-slots, handles, or custom shapes. Control systems employing encoders, photocells or electronic logic ensure precise registration, consistent spacing, and synchronization with printed films.

Overview of Spark Machinery PU32 Model capabilities

Our Macro Perforation Machine Models - Side Units

-

Side units are space-saving punching units designed to punch macroholes of various diameters and shapes on the moving film edge by means of die and punch driven by an electronic control system. This choice is the most advantageous and economical for those who need to make a few lines of holes on materials up to 600mm wide.

-

Reduced Dimension: The side units are designed with a reduced dimensions to maximize available space in existing production lines, allowing easy integration and ensuring high efficiency.

Versatility: These units can punch macroholes of various diameters and shapes, offering a versatile solution for a wide range of industrial applications.

Easy Integration: Because of their compact design, the side units can be easily integrated into existing equipment such as extruders, welding machines, slitters, bag machines, printing machines, and into all moving film processing lines.

-

These space-saving macro perforation punching units are widely used in the packaging industry and in plastic film production lines, providing an efficient and reliable solution for punching macro holes on edges of the moving film.

Spark Machinery’s Side Units overview:

Model PU14 side unit for shaped and circular MACRO HOLES from Ø Min. 1mm to Ø Max. 50mm

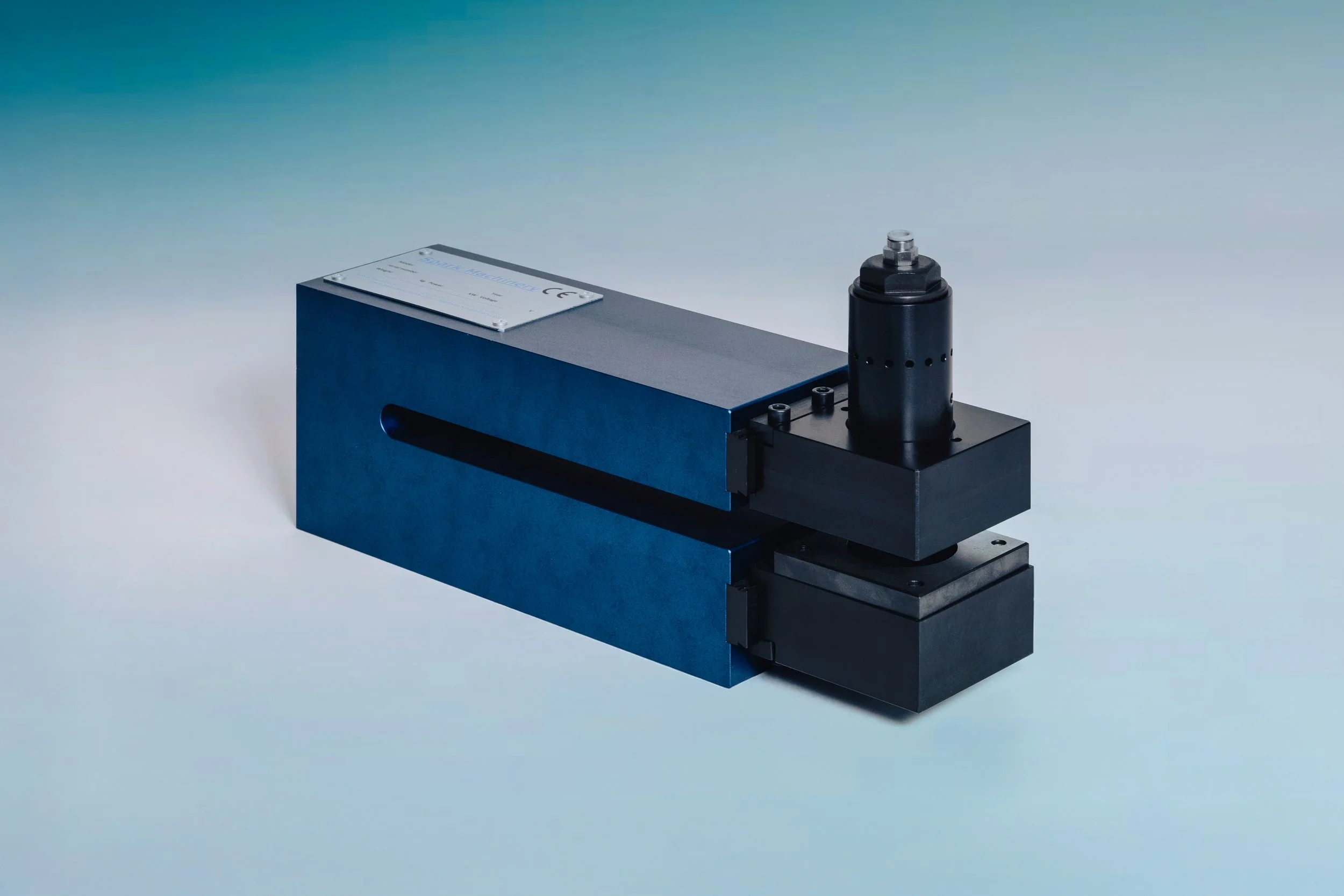

The PU14 side units are auxiliary systems engineered to create holes along the outer edges of moving films—both neutral and printed. They are designed for seamless integration into existing film processing lines, including extruders, welding units, slitters, bag-making and printing machines, or any continuous film transport setup. These units are particularly suited for producing handle openings of various dimensions as well as other custom-shaped perforations.

By using interchangeable dies and punches, the system can create holes in a wide range of diameters and shapes — from circular openings (Ø1 mm to 50 mm) to valve holes, euro-slots, drop holes, and handle holes of various sizes.

Beyond the standard tooling options, Spark Machinery also offers expert consultation and customized solutions, developing tailored dies and punches to meet each customer’s specific production requirements.

| TECHNICAL DATA SHEET | |

|---|---|

| Space for material passage | Max 100mm |

| Maximum speed | 200 mt minute* |

| Frequency of punching tools | 45 holes per second* |

| Hole Ø | Ø min. 1mm / Ø Max. 50mm |

| Hole type | Handle, circular, shaped, valve |

| Max. number of perforators per device | 1 |

| Position of the perforator | At the front of the device |

| * | This value depends on the type of material |

For more detailed information click the link below

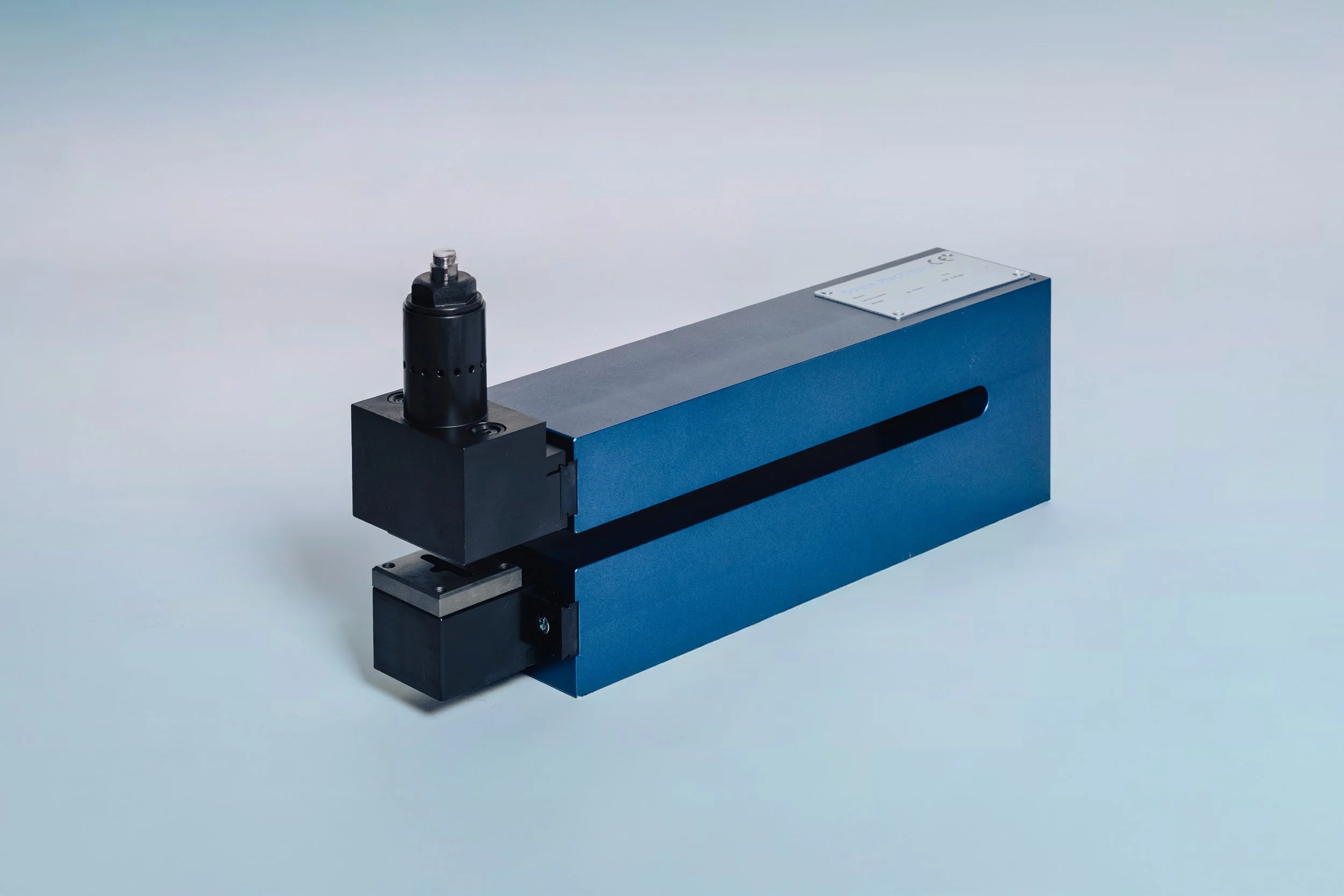

Model PU13 side unit for shaped and circular MACRO HOLES from Ø Min. 1mm to Ø Max. 50mm

The PU13 side units are precision accessories designed to perforate holes in continuously moving films, both neutral and printed. They integrate seamlessly into extrusion lines, welding machines, slitters, bag-making equipment, printing machines, and other continuous film processing systems. Ideal for applications like fruit and vegetable bags, garbage bags, paper bags, and foam sheets, this model excels in processes where film width frequently changes.

The punching mechanism features a lower die holder and an upper punch holder connected to a solenoid valve. As the film edge passes through the unit, the pneumatically driven punch and die system creates precise holes. Each unit operates independently, allowing different punching frequencies and forces for customized perforation patterns. The PU13 can be repositioned to adapt to film widths up to 600 mm without moving or realigning the tooling, ensuring fast setup and efficient operation.

| TECHNICAL DATA SHEET | |

|---|---|

| Space for material passage | Max 600mm |

| Maximum speed | 200 mt minute* |

| Frequency of punching tools | 45 holes per second* |

| Hole Ø | Ø min. 1mm / Ø Max. 50mm |

| Hole type | Circular holes, valve holes |

| Position of the perforators | On both sides of the device |

| * | This value depends on the type of material |

For more detailed information click the link below

Model PU12 side unit for MACRO perforation circular and shaped with holes from Ø Min. 1mm to Ø Max. 100mm

The Spark Machinery macro perforation unit PU12 is a space-efficient solution for creating macro holes of varying sizes and shapes along the edges of moving films, suitable for both neutral and printed materials. Designed for integration into film transport lines—such as slitters, extruders, printing presses, welders, and bag-making machines—these units are perfect for fruit and vegetable bags, garbage bags, paper bags, foam sheets, and agricultural films like mulching.

With interchangeable dies and punches, the system can produce circular holes from Ø1 mm to 100 mm, valve holes, handle openings, euro-slots, drop holes, mulching holes, and fully custom shapes. Beyond standard tooling, Spark Machinery also offers expert guidance and custom solutions to meet specific production needs.

| TECHNICAL DATA SHEET | |

|---|---|

| Space for material passage | 100mm - 200mm - 300mm - 400mm |

| Maximum speed | 200 mt minute* |

| Frequency of punching tools | 45 holes per second* |

| Hole Ø | Ø Min. 1mm / Ø Max. 100mm |

| Hole type | Circular - Valve Holes - Shaped |

| Max. number of perforators per device | 1 |

| Position of the perforator | At the front of the device |

| * | This value depends on the type of material |

For more detailed information click the link below

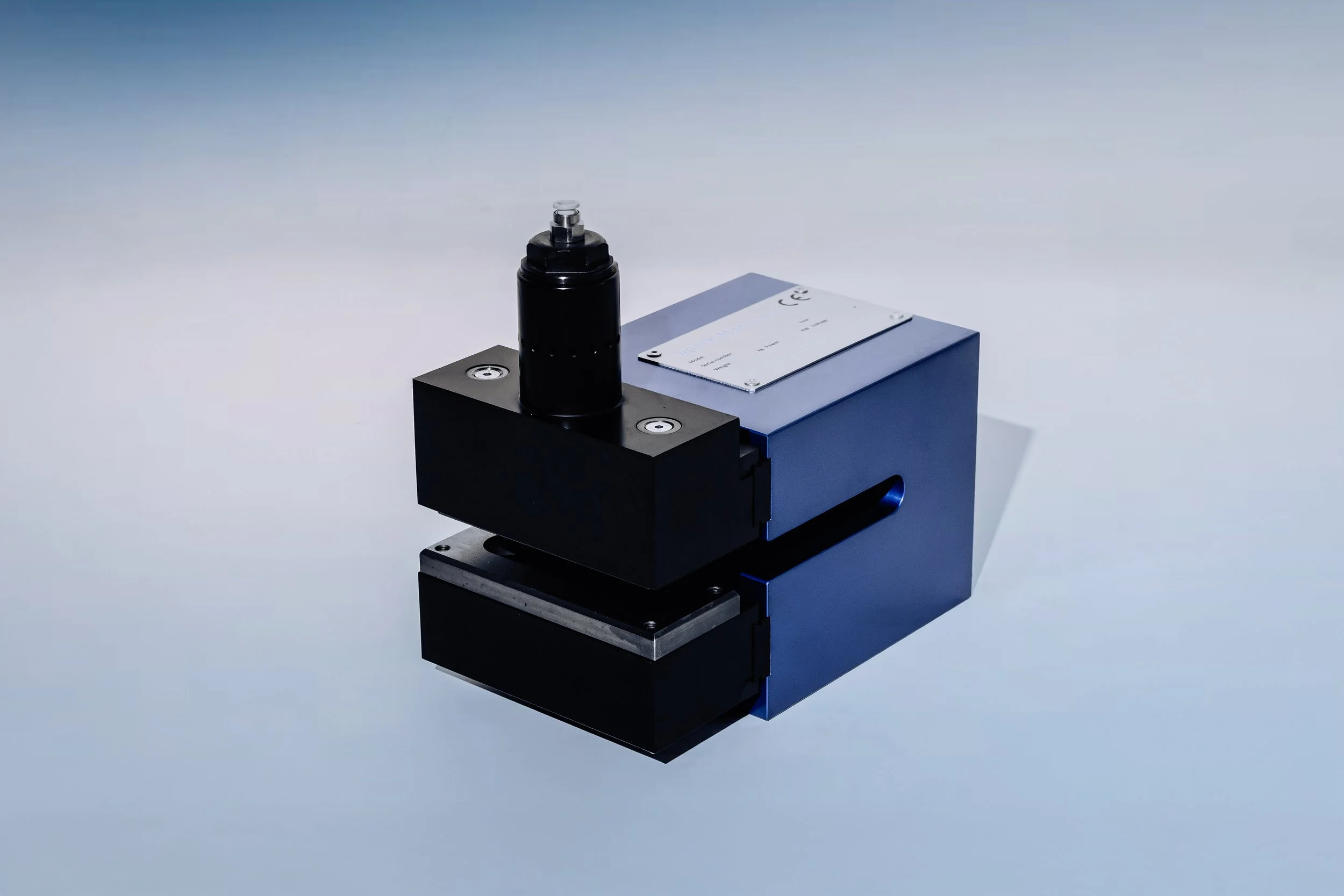

Model PU11 side unit for MACRO perforation circular and shaped with holes from Ø Min. 1mm to Ø Max. 50mm

The PU11 is a compact, space-saving macro perforation unit designed to punch macro holes of various sizes and shapes along the edges of moving film, suitable for both neutral and printed materials. It integrates easily into extrusion, slitting, welding, printing, and bag-making lines. The PU11 can mount perforators on both the front and sides—up to three punches—allowing multiple perforation lines at once. Each perforator operates independently, offering fully customizable patterns and high productivity for applications such as fruit and vegetable bags, garbage bags, paper bags, foam, and similar materials.

| TECHNICAL DATA SHEET | |

|---|---|

| Space for material passage | 100mm - 200mm |

| Maximum speed | 200 mt minute* |

| Frequency of punching tools | 45 holes per second* |

| Hole Ø | Ø min. 1mm* / Ø Max. 50mm |

| Hole type | Circular, valve holes, shaped |

| Max. number of perforators per device | 3 |

| Position of the perforator | 1 at the front of the device, 2 mounted on both side |

| * | This value depends on the type of material |

Model PU10 side unit for MACRO perforation circular and shaped with holes from Ø Min. 1mm to Ø Max. 16mm

The PU10 is a compact macro perforation unit engineered to create macro holes ranging from 1 to 16 mm in diameter along the edges of moving films. Suitable for both neutral and printed films, it is designed for seamless integration into film transport lines, including slitters, extruders, printing presses, sealing machines, bag-making equipment, and other continuous film processing systems. The PU10 is ideal for perforating fruit and vegetable bags, garbage bags, paper bags, foam sheets, and similar products, delivering reliable, high-speed performance in a compact footprint.

By selecting different interchangeable punches and dies, the PU10 can produce a variety of hole shapes, including circular openings, valve holes, butterfly holes, and half-moon holes, providing maximum flexibility and customization for diverse perforation requirements.

| TECHNICAL DATA SHEET | |

|---|---|

| Space for material passage | 100mm - 200mm |

| Maximum speed | 200 mt minute* |

| Frequency of punching tools | 45 holes per second* |

| Hole Ø | Ø min. 1mm / Ø Max. 16mm |

| Hole type | Circular, valve, butterfly and half-moon holes |

| Max. number of perforators per device | 1 |

| Position of the perforator | At the front of the device |

| * | Value affected by the type of material |

For more detailed information click the link below

For more detailed information click the link below

Our Macro Perforation Machine Models - PU Bridges

-

Bridge macro perforation units provide a dependable and flexible solution for creating large holes of different shapes and diameters in moving materials—particularly in neutral or printed plastic films. These systems are specifically designed to operate as integrated modules within continuous film processing lines.

-

Speed and Precision:

Bridge macro perforators ensure fast, stable, and accurate operation, delivering precise perforations even at high production speeds. Depending on the film type and the desired perforation pattern, these machines can reach working speeds of up to 250 m/min.Versatility:

This technology is highly adaptable and suitable for a broad range of applications. It is frequently used for fruit and vegetable packaging, agricultural film perforation, and many other processes requiring holes of various shapes and sizes in flexible materials. Thanks to the Industry 4.0 software, the perforation pattern can be easily modified to meet specific production needs, while punching recipes can be saved and recalled at any time for future use. This feature greatly enhances flexibility and production efficiency.Seamless Integration:

These punching modules can be easily incorporated into existing production lines such as slitters, extruders, printers, welding machines, and rewinders. This allows for smooth integration, increased efficiency, and exceptional adaptability in diverse manufacturing environments. -

The macro-punching units are also widely employed in industries such as food packaging, shopping bags, garbage bags, mulching films, packaging films, and more.

Spark Machinery’s Bridge Units overview:

Model PU2 MACRO PERFORATION units for holes from Ø Min. 1mm to Ø Max. 50mm

For more detailed information click the link below

-

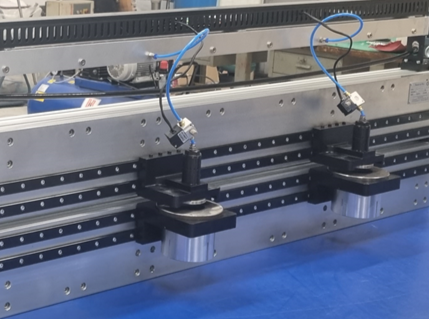

Spark Machinery's PU2 macro perforation units are engineered to efficiently create holes of various shapes and diameters in moving flexible materials, such as plastic films. Such models are designed for integration into continuous film processing lines, offering high-speed and stable performance.

-

The PU20 is a compact and efficient punching unit that delivers precise perforations at speeds up to 200 meters per minute. It operates with a maximum frequency of 45 Hz, allowing for rapid processing of materials. The unit is equipped with an intuitive electronic control system (QCSM1) that enables power and position control for each individual punching tool, as well as the management of punching recipes, including insertion, storage, and recall.

-

The PU22 enhances the capabilities of the PU20 by incorporating two perforation bridges, effectively doubling the punching frequency. This design allows for higher throughput and greater flexibility in production lines, making it suitable for applications requiring increased perforation density or faster processing speeds. Like the PU20, the PU22 is equipped with an advanced electronic control system for precise operation and efficient recipe management

| TECHNICAL DATA SHEET | |

|---|---|

| Web Width | 400mm to max. 2200mm |

| Maximim speed | 200 mt minute* |

| Frequency of punching tools | 45 holes per second (PU20) 90 holes per second (PU22) |

| Hole Ø | Ø min. 1mm / Ø Max. 50mm |

| Minimum transverse distance between holes | 30mm (PU20) 15mm (PU22) |

| Hole type | Circular, valve holes, euroslot, handle holes and customized holes |

| Compressed air hose inlet | Min. 12 externally calibrated tube |

| * | This value depends on the type of material |

For more detailed information click the link below

For more detailed information click the link below

Model PU3 MACRO PERFORATION units for holes from Ø Min. 1mm to Ø Max. 50mm

-

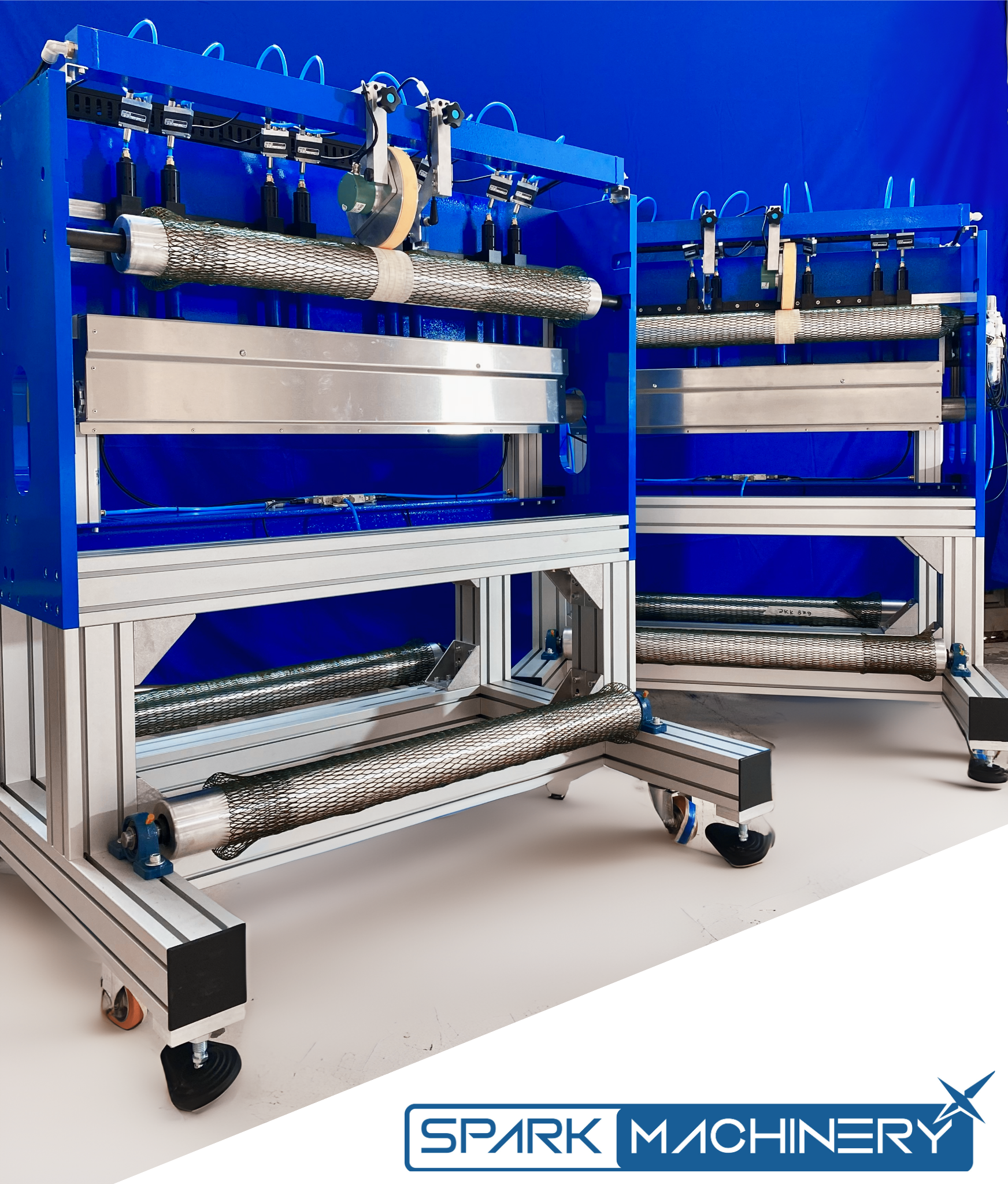

The PU30 and PU32 from Spark Machinery are advanced macro perforation units designed to create large holes of various shapes and sizes in moving flexible materials, such as neutral or printed plastic films. Both units are engineered for smooth integration into continuous production lines, delivering high-speed, precise perforations with enhanced versatility and operator comfort.

-

The PU30 is a stable and compact punching unit, ideal for applications requiring precise perforations at high speeds. It features an advanced electronic control system that allows:

Individual control of each punching tool

Management and storage of punching recipes

The unit can operate at speeds of up to 250 m/min with punching frequencies up to 45 Hz, depending on material and perforation pattern. For enhanced working conditions, the PU30 can be equipped with optional soundproofing to reduce operational noise. Additionally, an optional blow-down system is available to efficiently remove cut waste from the punching area, keeping the production line clean and minimizing downtime.

-

The PU32 builds on the PU30 by incorporating two perforation bridges, effectively doubling the punching frequency to 90 Hz. This makes it ideal for applications requiring higher perforation density or faster production speeds. Like the PU30, the PU32 offers:

Advanced electronic control system

Optional soundproofing for quieter operation

Optional blow-down technology for efficient cut-waste aspiration

This combination of features ensures high productivity while maintaining a cleaner, quieter, and more efficient production environment.

Key Features of PU30 and PU32

High-Speed Performance: PU30 up to 250 m/min; PU32 with double punching frequency for maximum throughput

Precision Control: Individual management of punching tools and recipe recall for flexible production

Material Versatility: Suitable for PP, PET, PVC, LDPE, HDPE, BOPP, CPP, laminates, leather, eco-leather, compostable and biodegradable materials, non-wovens, Tyvek, foam, raffia, and paper

Optional Soundproofing: Reduces operational noise for a safer, more comfortable work environment

Optional Blow-Down Technology: Optimized removal of cut waste ensures cleaner operation and prevents clogging

Lower Beam Pneumatic System: The lower beam can be opened via pistons, facilitating the change and alignment of perforation tools during work changes while providing added structural stability

| TECHNICAL DATA SHEET | |

|---|---|

| Web Width | 400mm to max. 3000mm |

| Maximim speed | 250 mt minute* |

| Frequency of punching tools | 45 holes per second (PU30) 90 holes per second (PU32) |

| Hole Ø | Ø min. 1mm / Ø Max. 50mm |

| Minimum transverse distance between holes | 30mm (PU30) 15mm (PU32) |

| Hole type | Circular, valve holes, euroslot, handle holes and customized holes |

| Position of the perforator | On one (PU30) or both (PU32) sides of the device |

| * | This value depends on the type of material |

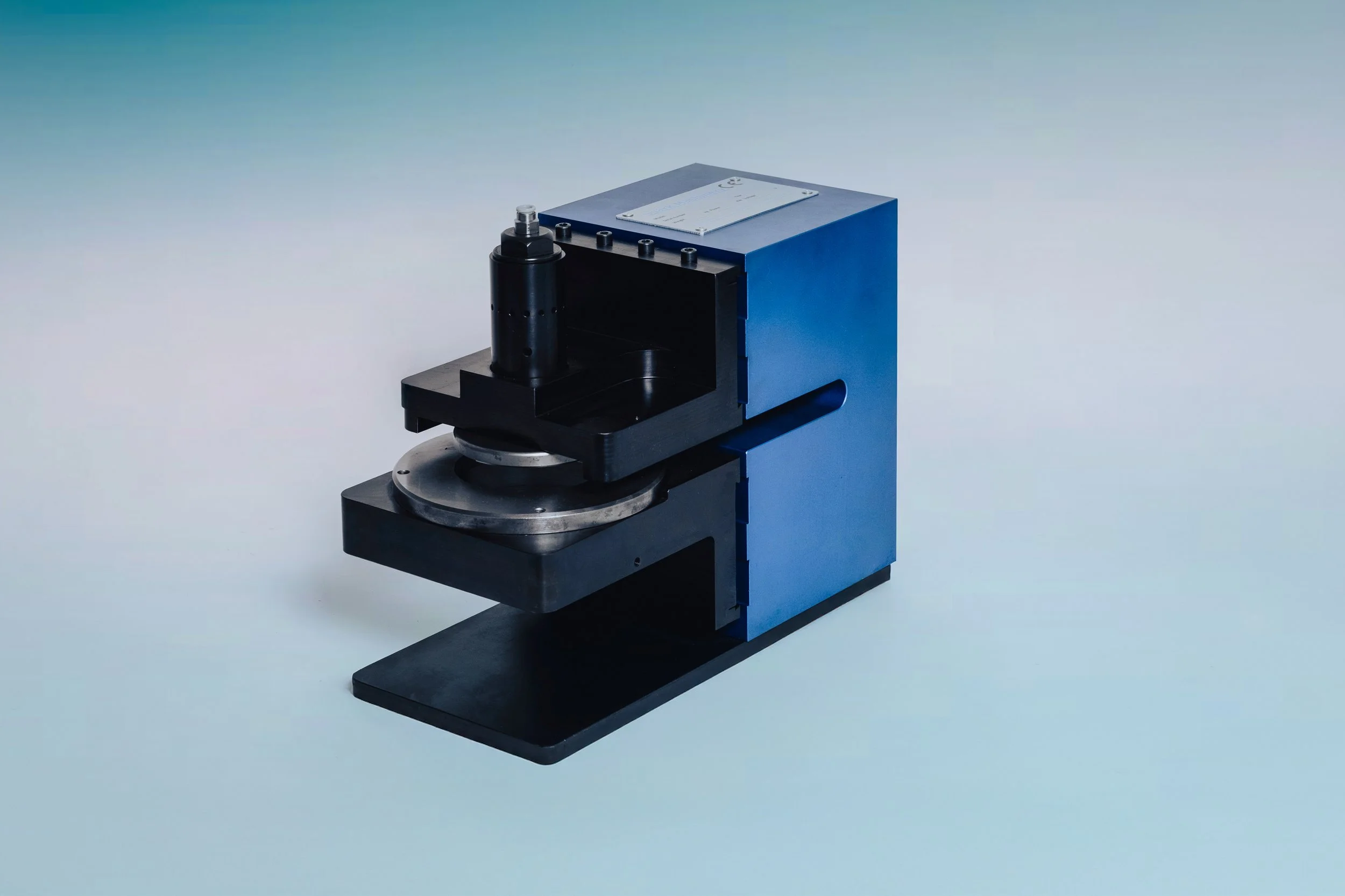

Model PU4 MACRO PERFORATING units for holes from Ø Min. 1mm to Ø Max. 100mm

-

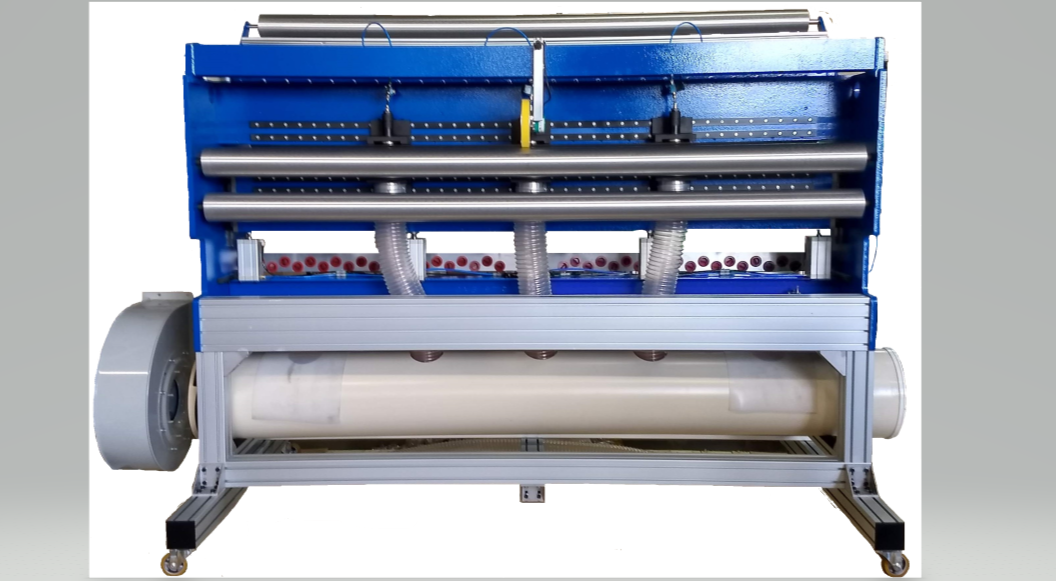

The PU40 and PU42 are specialized macro perforation units designed for creating large-diameter holes in moving plastic films, particularly for agricultural mulching purposes. These units are engineered to be seamlessly integrated into continuous film processing lines, such as extruders, slitters, and printing or welding machines.

-

The PU40 is a robust and efficient punching unit, ideal for applications requiring precise perforations at high speeds. It features an advanced electronic control system that allows:

Individual control of each punching tool

Management and storage of punching recipes

The unit can operate at speeds of up to 200 m/min with punching frequencies up to 45 Hz, depending on material and perforation pattern. The PU40 is designed to create holes ranging from 1 mm to 100 mm in diameter, accommodating various hole shapes such as circulars, valve, euroslots, handle and custom holes

-

The PU42 builds on the PU40 by incorporating two perforation bridges, effectively doubling the punching frequency to 90 Hz. This makes it ideal for applications requiring higher perforation density or faster production speeds. Like the PU40, the PU42 offers:

Advanced electronic control system

Ability to create holes ranging from 1 mm to 100 mm in diameter

Compatibility with various hole shapes including circular, valve, euroslot, handle, and custom designs

The PU42 is designed for high-speed operation, with a maximum speed of 200 m/min, depending on material and perforation pattern.

Key Features of PU40 and PU42

High-Speed Performance: PU40 up to 200 m/min; PU42 with double punching frequency for maximum throughput

Precision Control: Individual management of punching tools and recipe recall for flexible production

Material Versatility: Suitable for PP, PET, PVC, LDPE, HDPE, BOPP, CPP, laminates, leather, eco-leather, compostable and biodegradable materials, non-wovens, Tyvek, foam, raffia, and paper

Lower Beam Pneumatic System: The lower beam can be opened via pistons, facilitating the change and alignment of perforation tools during work changes while providing added structural stability

Seamless Integration: Compatible with extruders, welders, slitters, bag-making machines, printing machines, and rewinders

| TECHNICAL DATA SHEET | |

|---|---|

| Web Width | min. 1000mm to max. 5000 mm |

| Maximum speed | 200 mt minute* |

| Frequency of punching tools | 45 holes per second (PU40) 90 holes per second (PU42) |

| Hole Ø | Ø min. 1mm / Ø Max. 100mm |

| Minimum transverse distance between holes | 30mm (PU40) 15mm (PU42) |

| Hole type | Circular, valve and custom holes |

| Position of the perforator | On one (PU40) or both (PU42) sides of the device |

| * | Value affected by material type and hole diameter |

Model PU4 Macroperforators for mulching applications

For more detailed information click the link below

Model PU50 MACRO PERFORATING unit for holes from Ø Min. 50mm to Ø Max. 100mm

-

The PU50 is a compact and cost-effective macro perforation unit designed specifically for creating large-diameter holes (50–100 mm) in moving plastic films, primarily for agricultural mulching applications. Its streamlined design makes it ideal for operations with limited space, offering a practical solution without compromising on performance.

-

Compact Design: Optimized for installations where space is at a premium, making it suitable for smaller production lines.

High-Speed Operation: Achieves speeds up to 200 m/min, with a punching frequency of 35 Hz, depending on material composition and hole spacing.

Versatile Hole Sizes: Capable of producing holes ranging from 50 mm to 100 mm in diameter, accommodating various agricultural needs.

Pneumatic Punching System: Utilizes a punch and die system driven by pneumatic movement, ensuring clean and efficient hole creation.

User-Friendly Electronics: Features the QCSM1 control system, allowing for independent management of each punching tool, recipe storage, and remote operation via PC or tablet.

Seamless Integration: Designed to be integrated as a host unit in film transport lines such as slitters, extruders, printing presses, or welding machines.

| TECHNICAL DATA SHEET | |

|---|---|

| Web width | min. 600 to max. 1600 |

| Maximum speed | 200 mt minute* |

| Frequency of punching tools | 35 holes per second* |

| Hole Ø | Ø min. 50mm / Ø Max. 100mm |

| Minimum transverse distance between holes | 30mm |

| Hole type | Circular, valve and custom holes |

| Position of the perforator | On one side of the device |

| * | Value affected by the type of material |

What exactly is Macro Perforation?

Macro perforation is a process used to create relatively large holes — typically from a few millimeters up to several centimeters in diameter — in flexible materials such as plastic film, paper, or laminates. These perforations are made using mechanical punches and dies while the material is moving through a production line. Macro perforation improves air circulation, moisture control, and product visibility, making it ideal for applications like agricultural mulching films or food packaging.

In contrast, micro perforation produces much smaller holes — often invisible to the naked eye — using lasers or needles. Micro perforation is mainly used to regulate gas exchange or humidity within packaging (for example, to extend the shelf life of fresh produce). In short, macro perforation creates large, visible holes for ventilation and functionality, while micro perforation creates tiny, controlled openings for preservation and product protection.

Advantages of Macro Perforation

Enhanced Breathability: Allows controlled airflow to keep products fresher for longer.

Improved Product Freshness: Reduces condensation and preserves natural quality.

Easier Tear-Open Functionality: Adds convenience with easy, clean opening.

Better Moisture Control: Helps balance humidity and prevent spoilage.

Optimized Storage & Shelf Life: Extends product longevity and maintains appearance on shelf

How a Macro Perforation Machine Works

A film web is driven through the machine using rollers and kept under tension via a controlled drive system.

An encoder tracks web speed, while photocells detect registration marks; together they synchronize punch timing to the moving substrate.

The core punching module consists of punches and dies mounted on upper and lower beams; punches (male tools) are driven (pneumatically and solenoid-actuated) into dies to cut holes.

Cut waste (slugs) is evacuated via suction or optional vacuum, keeping the tooling area clean.

In some models, the lower beam can be pneumatically opened via pistons to allow quick tool change and alignment, while when closed it contributes to structural rigidity.

The electronic control system handles individual control of each tool (power, position, timing), recipe management (save/recall patterns), and synchronization with the encoder/photocell logic.

Why choose Spark Machinery?

Uncompromising Quality, Reliability & Performance

Spark Machinery designs and builds high-performance systems known for their precision, durability, and consistent output. Our machines operate reliably even under high-speed, high-demand production conditions, delivering top-tier results with minimal downtime.Tailor-Made Solutions for Every Customer

We don’t believe in one-size-fits-all. Every system is engineered based on the specific needs of our customers—whether it’s material type, production speed, perforation pattern, or integration with existing lines. This ensures optimal efficiency and seamless operation from day one.End-to-End Support

Our commitment goes beyond machine delivery. We offer expert guidance during project planning, hands-on support during installation and training, and responsive service throughout the machine’s operational life. We're your partner before, during, and after purchase.Driven by Research & Innovation

At Spark Machinery, continuous improvement is part of our DNA. We invest heavily in R&D and testing to develop cutting-edge perforation technologies, improve system capabilities, and stay ahead of evolving market demands. Innovation is what keeps our customers competitive—and we deliver it with every machine.

Get expert advice for your Perforation Needs

Choosing the ideal macro-perforating machine can be a complex decision, given the diverse technologies and material considerations involved. To ensure you select the perfect solution for your specific needs, we invite you to a free, no-obligation consultation with our experts. Benefit from personalized insights into how the macro perforation technology can optimize your production, enhance product quality, and drive efficiency, ensuring a smart investment tailored to your success.

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

FEDERICA CANTAGALLI

Commercial Export Office