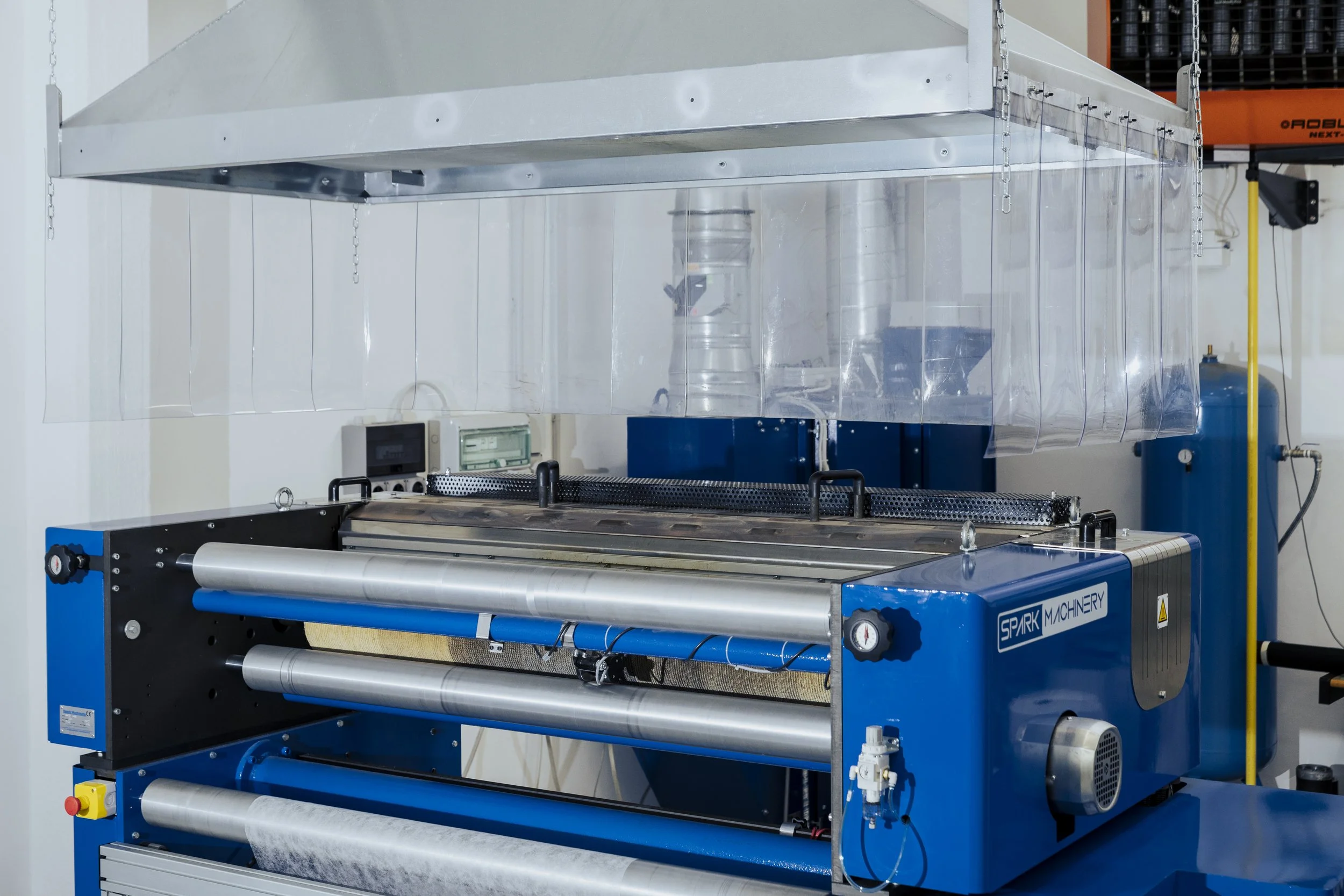

Hot Needle Perforation Machines by Spark Machinery

Our Hot Needle Perforation Machine Models

-

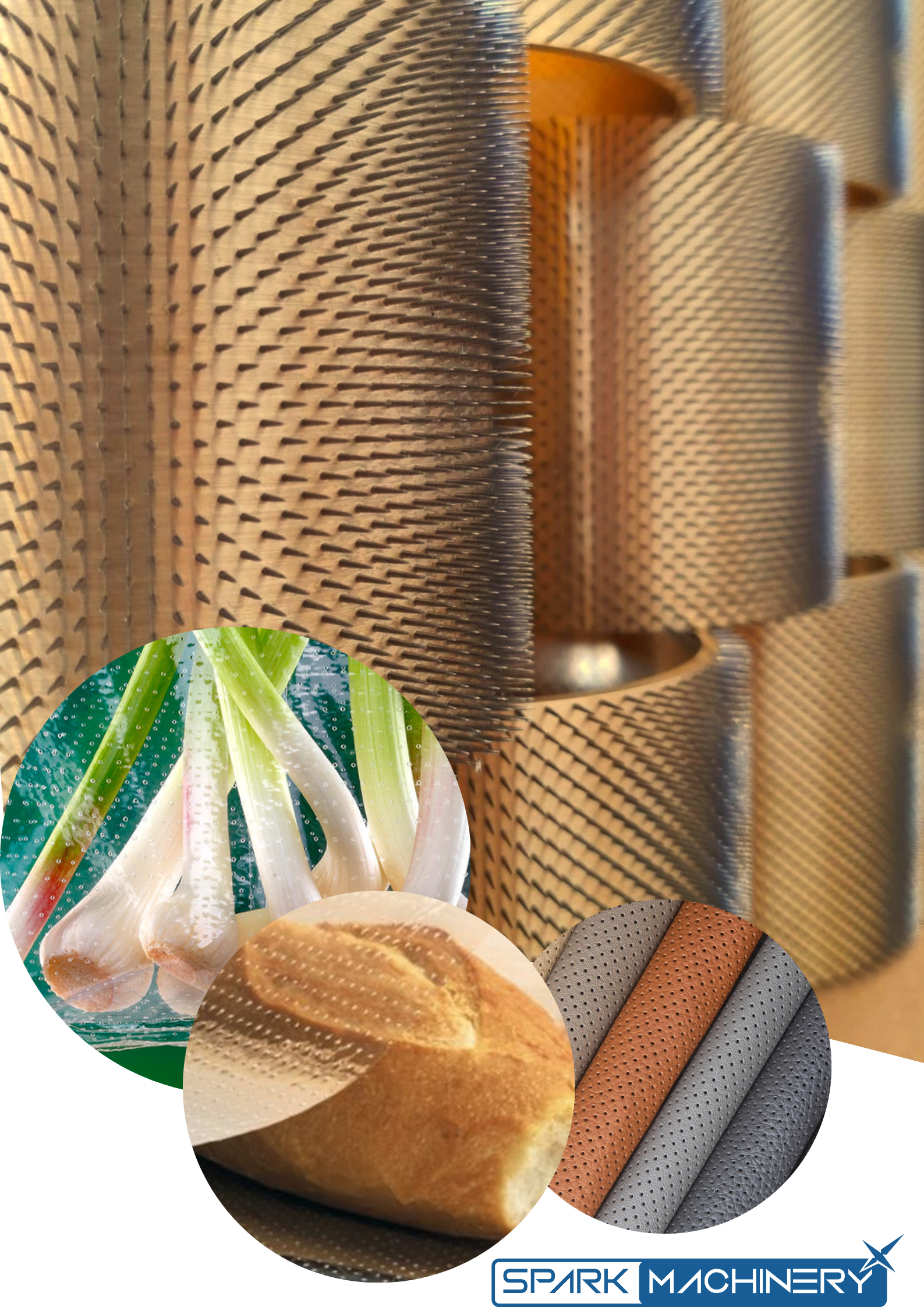

High‑precision micro‑perforation on moving film webs via electrically heated needle rollers. The system melts and pierces the film with heated needles, delivering controlled, clean perforations—even at high needle densities—without mechanical cutting.

-

Ideal for producing breathable packaging, moisture‑control features, and permeability in films across food packaging, pharmaceuticals, textiles, automotive interiors, and technical fabrics. Suitable for mono‑ and bi‑oriented materials, shrink‑wrap films, rubbers, faux leather, laminates, wood veneer, PVC, aluminum, and paper substrates.

-

Heating & Perforation: Electrically heated needle rollers (via infrared lamps with PID control) housed in an insulated chamber ensure uniform temperature and precise, melt-based perforation.

Control System: Industry 4.0-ready with touchscreen interface, recipe management, and automatic, pause, and manual modes. Includes safety shutters and film detection via photocell to prevent perforation when film is absent.

Adjustment & Safety: Micrometric or motorized penetration adjustment for precise depth control. Safety features include pneumatic shutters and cool-down rotation to protect components.

Model HN100 HOT MICRO PERFORATION system for holes from 200µ to 2mm with motorized needle roller of Ø100mm

Operation

The running film arrives at the machine and passes through the heated motorized needle roller and the counter roller, which approach each other and perforate the material. The rollers are approached through the pneumatic system, and the perforation adjustment is implemented by two micrometer screws.

Control & Adjustment of the HN100 is entrusted to our software designed for 4.0 integration from the electrical control panel. The operator via touch screen manages all operations inherent to the device such as temperature control, control of heating elements, emergency activation and needle shaft rotation.

| TECHNICAL DATA SHEET | |

|---|---|

| Needle shaft Ø | 100mm |

| Hole Ø | Ø min. 200µ / Ø max. 2 mm* |

| Movement and power | Asynchronous motor / 400 V+N+T - 50Hz |

| Penetration adjustment | Micrometric screws with graduated knobs |

| Maximum speed | 150 mt minute* |

| Heating power | 8 Kw / mt |

| Maximum temperature | 300° C |

| Air pressure | 6 Bar |

| Counter roller movement | Pneumatic Movement |

| * | Value affected by the type of material |

For more detailed information click the link below

Model HN200 HOT MICRO PERFORATION system for holes from 200µ to 2mm with motorized needle roller of Ø200mm

Description

This system is designed to make "hot" micro holes on moving films of various materials and thicknesses and is to be installed as a host unit in film transport lines, such as slitters, extruders, printing and welding machines. The HN 200 guarantees perfect micro holes on mono- or bi-oriented materials and even with low heat input; it is ideal for delicate processing on shrinkable material or with very high needle density per cm2..

Operation

The HN200 is an electrically heated needle microperforator. The running film arrives at the device and is perforated by the motorized needle shaft that is approached by the contrast roller designed to support the material. The micro-perforation is achieved by melting and perforating the material, caused by the needles fixed on the interchangeable bronze sleeves. The needle sleeves are mounted on the needle shaft placed inside an insulated chamber and brought to an adequate temperature by the group of infrared lamps.

| TECHNICAL DATA SHEET | |

|---|---|

| Needle shaft Ø | 200mm |

| Hole Ø | Ø min. 200µ / Ø Max. 2mm* |

| Movement and power | Asynchronous motor / 400 V+N+T - 50Hz |

| Penetration adjustment | Micrometric screws with graduated knobs |

| Maximum speed | 200 mt minute* |

| Heating power | 24 Kw / mt |

| Maximum temperature | 400° C |

| Air pressure | 6 Bar |

| Counter roller movement | Motorized Motion storable in a recipe |

| * | Value affected by the type of material |

For more detailed information click the link below

Model HN200-PL HOT MICRO PERFORATION system for holes from 100µm to 2mm with Ø200mm motorized needle roller

Description

This equipment is designed to make "hot" micro holes on moving films of rubber, faux leather, wood veneer and various thicker and more puncture-resistant materials, and is to be inserted as a host unit in film transport lines, such as cutters, extruders, printing presses, welding machines. The HN200-PL is a motorized unit designed for greater penetration with a synchronization system that ensures perfect micro holes on a variety of materials; ideal for delicate work on heat-shrinkable material, for works that require holes with a very high density of needles per cm2 and to process mono or bi-oriented materials..

| TECHNICAL DATA SHEET | |

|---|---|

| Ø Needle shaft | 200mm |

| Ø Hole | Ø min. 100µm / Ø max. 2mm* |

| Movement and power | Asynchronous motor / 400 V+N+T - 50Hz |

| Penetration adjustment | Motorized, controlled by touch screen |

| Maximum Speed | 100 mt/minute* |

| Heating power | 16Kw / mt |

| Maximum temperature | 240° C |

| Air pressure | 6 Bar |

| Counter roller movement | Motorized - 2 actuators |

| Control System | Electrical control panel with integrated touch screen |

| * | Value affected by the type of material |

For more detailed information click the link below

A short introduction: What is Hot Needle Perforation?

Hot needle microperforation is a process that uses heated needles to create precise, small holes in plastic films and other flexible materials. As the needles briefly contact the surface, they melt through it, forming clean perforations with sealed edges. This thermal sealing prevents tearing, improves mechanical strength, and enhances the overall durability of the material, especially during handling, sealing, or forming processes.

The method allows for accurate control over hole size, spacing, and pattern, making it ideal for applications that require specific permeability characteristics. These include breathable packaging for fresh produce, moisture regulation, and easy-tear zones for consumer convenience. Hot needle microperforation is compatible with a wide range of polymer-based films, such as polyethylene, polypropylene, and multilayer laminates, making it a reliable and flexible solution for food, medical, and industrial packaging applications.

How Do Hot Needle Perforation Machines Work?

Hot Needle Perforation machines use a precise thermal-mechanical process to create micro-holes in flexible materials such as plastic films. This process enhances breathability, shelf life, or user interaction (e.g., easy-open packaging), while maintaining the structural integrity of the material. Here’s a step-by-step breakdown of the technical principle behind these machines:

Technical Principle & Step-by-Step Process:

Material Feeding:

The film or material is unwound from a roll and guided through the machine using tension-controlled rollers.

Consistent tension ensures smooth movement and accurate perforation.

Needle Heating:

Stainless steel or alloy needles are mounted on a rotating drum or linear array.

These needles are electrically heated to a controlled temperature, usually between 200°C and 400°C, depending on the material type and thickness.

Contact & Penetration:

As the film moves past the heated needle array, the needles briefly and precisely contact the surface.

The heat melts the material upon contact, creating clean, round micro-holes without tearing or pushing the material.

Hole Formation:

The melted material around the hole self-seals, forming smooth, reinforced edges.

This prevents hole enlargement or tearing during further processing or use.

Rewinding:

The perforated film is wound onto a finished roll, ready for downstream processing such as printing, laminating, or bag-making.

Advantages of Hot Needle Perforation

Clean and Sealed Hole Edges

The heat from the needles melts the film during perforation, creating smooth, sealed edges that prevent tearing and reduce the risk of material degradation over time.

High Precision and Consistency

Electrically heated needles and synchronized film movement ensure uniform hole size, spacing, and alignment across the entire web—critical for quality-sensitive applications.Improved Mechanical Strength of the Material

Unlike mechanical punching, hot needle perforation doesn’t introduce stress fractures. The sealed edges preserve the structural integrity of the film, even under tension or heat sealing.Advantages Over Alternative Methods

Compared to cold punching or laser perforation, hot needle systems are generally more energy-efficient, better at preserving film strength, and simpler to maintain—especially when sealing quality and mechanical durability are key requirements.

Why choose Spark Machinery?

Uncompromising Quality, Reliability & Performance

Spark Machinery designs and builds high-performance systems known for their precision, durability, and consistent output. Our machines operate reliably even under high-speed, high-demand production conditions, delivering top-tier results with minimal downtime.

Tailor-Made Solutions for Every Customer

We don’t believe in one-size-fits-all. Every system is engineered based on the specific needs of our customers—whether it’s material type, production speed, perforation pattern, or integration with existing lines. This ensures optimal efficiency and seamless operation from day one.End-to-End Support

Our commitment goes beyond machine delivery. We offer expert guidance during project planning, hands-on support during installation and training, and responsive service throughout the machine’s operational life. We're your partner before, during, and after purchase.Driven by Research & Innovation

At Spark Machinery, continuous improvement is part of our DNA. We invest heavily in R&D and testing to develop cutting-edge perforation technologies, improve system capabilities, and stay ahead of evolving market demands. Innovation is what keeps us competitive, and we deliver it with every machine.

Areas of application of our Hot Needle Perforator Machines

Microperforation of PE, PP, and multilayer films to regulate moisture and airflow in fresh produce packaging.

Creation of easy-tear zones in pouches and flowpacks without compromising material strength.

Nonwoven Textiles

Perforation of hygiene products (e.g. diapers, wipes) to enhance breathability and comfort.

Ventilation zones in medical textiles such as gowns and drapes.

Technical Films & Foils

Venting holes in shrink wrap, stretch film, and foil laminates for heat-sensitive or pressurized contents.

Steam-release perforation for microwaveable food-grade laminates.

Food Industry Applications

Perforated films for bakery and produce to manage humidity and prevent condensation.

Ventilation in meat and dairy packaging to optimize shelf conditions.

Industrial & Technical Textiles

Perforation of breathable membranes, filter substrates, and protective fabrics.

Precision hole patterns in composites or coatings for ventilation or weight reduction.

Get expert advice for your Micro Perforation Needs

Choosing the ideal micro-perforating machine can be a complex decision, given the diverse technologies and material considerations involved. To ensure you select the perfect solution for your specific needs, we invite you to a free, no-obligation consultation with our experts. Benefit from personalized insights into how the right hot, cold, or laser perforation technology can optimize your production, enhance product quality, and drive efficiency, ensuring a smart investment tailored to your success.

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

DANA NURTAZINA

Commercial Export Office