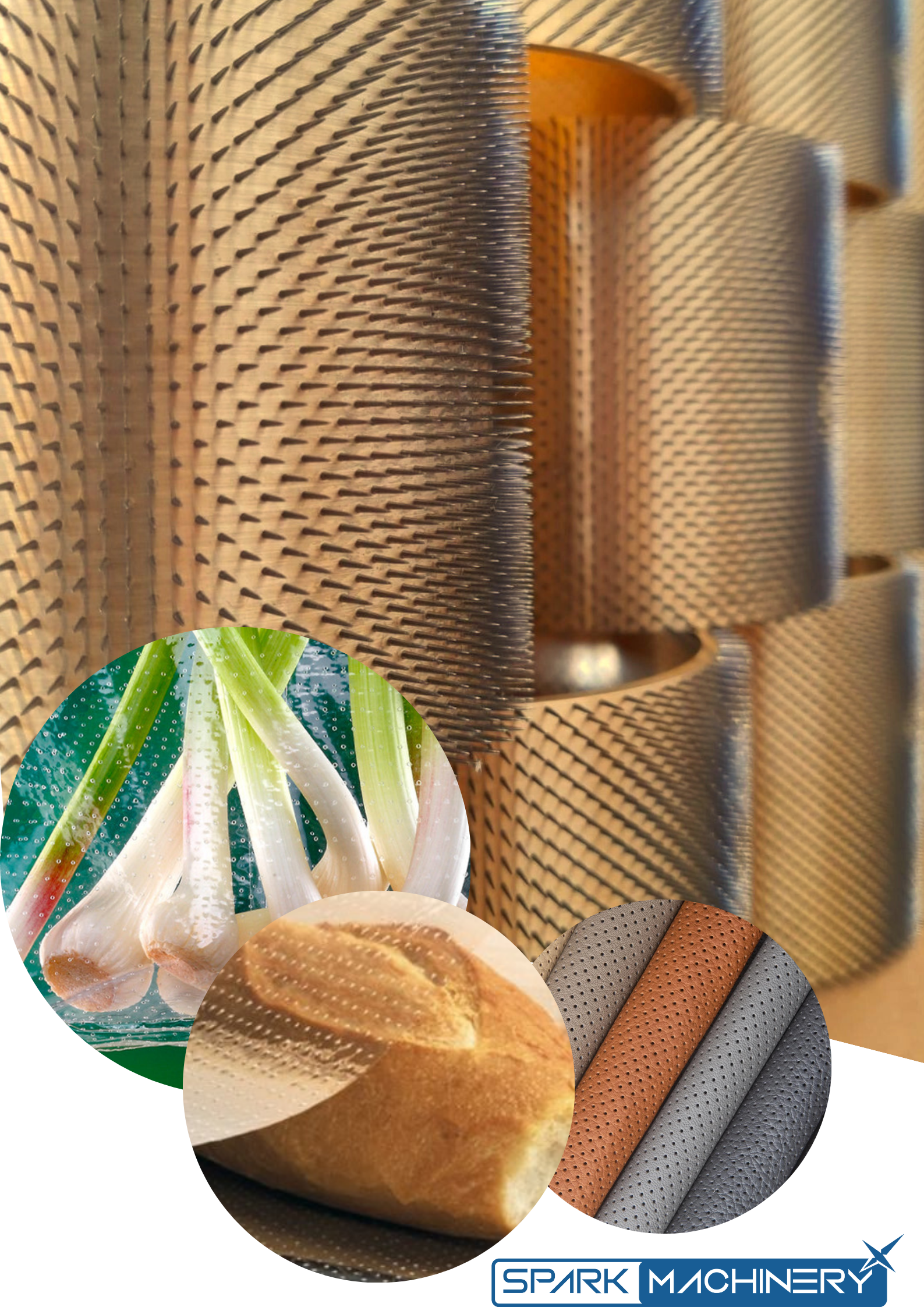

Cold Needle Perforation Machines by Spark Machinery

Our Cold Needle Perforation Machine Models

-

Cold microperforators are a versatile and simple technology used to perforate thin materials using needle cylinders offering a combination of simplicity, efficiency and affordable cost that makes them a popular choice in many industries. This technique is commonly known for the use of needles that perform the perforation of the material without generating heat, thus ensuring the preservation of the material's characteristics.

-

Cold micro-perforation technology is widely applied across multiple industries. In packaging, it is used to perforate plastic films to provide ventilation, moisture control, and other functional enhancements. In textiles, it enables the perforation of fabrics for medical applications, technical purposes, and decorative finishes. The automotive sector relies on it for precision perforation of interior materials such as fabrics, synthetic leathers, and plastic panels. In the medical field, it plays a key role in creating transdermal drug-delivery patches by perforating membranes used in medical devices.

-

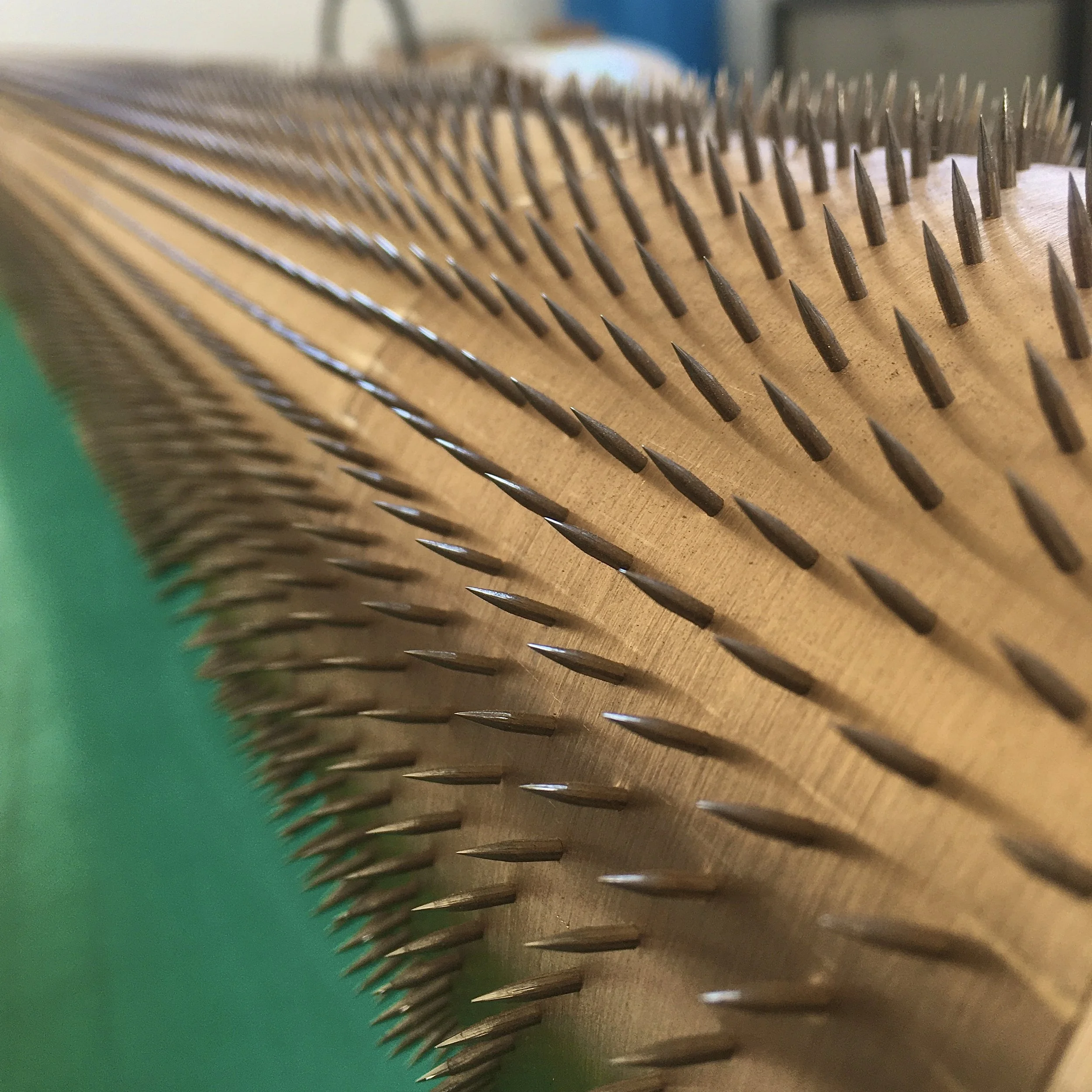

Spark Machinery’s cold needle perforators employ a needle shaft and a opposing counter roller to mechanically pierce moving film without heating. Perforation is controlled via pneumatic actuation that engages or retracts the contrast roller, while micrometric screws provide fine adjustment of penetration depth.

In most models, film transport is passive—via film drag—although motorized rollers are available in CN-M models. The counter roller may be made of ground bristles or rubber depending on the substrate.

Model CN-M COLD MICRO PERFORATION system for holes from 80µ to 1mm with motorized needle rolls of Ø 60mm - 100mm - 200mm

Description

The CN Series micro-hole perforators are compact, lightweight, and highly adaptable units engineered for integration into film-processing lines such as slitters, extruders, printing presses, welding machines, and other systems handling continuous web materials. These machines produce precise micro-holes of varying diameters on moving films with high accuracy and consistency. Their reduced footprint allows easy installation as host modules within existing production setups. Typical applications include micro-perforation for produce bags, breathable and moisture-regulating films, thermal and acoustic insulation layers, electronic product packaging, and other technical films requiring controlled permeability.

Operation

The film passes between a motorized needle shaft and a pneumatically actuated counter roller, which perforate the material. Penetration depth is finely regulated via dual micrometric screws. Operation is controlled through Industry 4.0-ready software with a touchscreen interface on the control panel. The needle shaft is powered by an asynchronous motor with encoder, enabling tracking synchronization with the host line speed.

| TECHNICAL DATA SHEET | |

|---|---|

| Needle shaft Ø | 60mm - 100mm - 200mm |

| Hole Ø | Min. Ø80µ - Max. Ø1mm |

| Movement | Movement by asynchronous motor 400 V+N+T - 50 Hz |

| Penetration adjustment | Micrometric screws with graduated knobs |

| Maximum speed | 400 mt minute* |

| Counter roller approach movement | Pneumatic movement |

| Air Pressure | 6 Bar |

| * | Value influenced by material type and machine configuration |

For more detailed information click the link below

Model CN-CP COLD MICRO PERFORATION system for holes from 80µ to 1.8mm with interchangeable needle roller

Description

The CN-CP MICROPERFORATOR is a model designed to make micro holes of various diameters on moving materials and is to be inserted as a host unit in continuous material transport lines. Solid and functional, it guarantees the best performance for making perforated materials for construction, particularly in the area of thermal and acoustic insulation

Operation

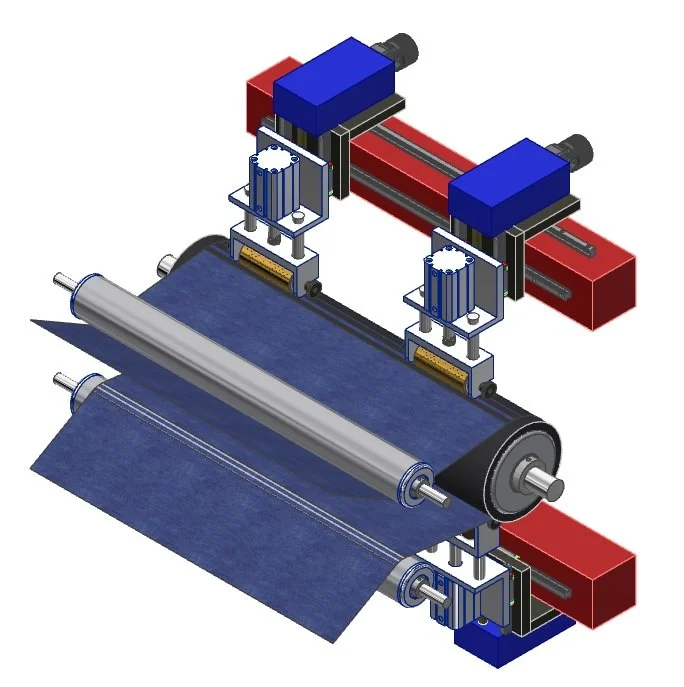

Perforation is done by the perforating unit which consists of two needle shafts. The film passes between two needle shafts, which come into contact with the material and perforate it continuously. The shafts approach each other through the pneumatic system and an asynchronous motor.

| TECHNICAL DATA SHEET | |

|---|---|

| Needle shaft Ø | Variable |

| Hole Ø | Ø Min. Ø80µ - Max. Ø1,8mm |

| Movement | Movement through dragging of the material |

| Penetration adjustment | Asynchronous motor 400 V+N+T - 50 Hz and Pneumatic movement |

| Air pressure | 6 Bar |

| Material of needle segments | Bronze, steel, aluminum |

For more detailed information click the link below

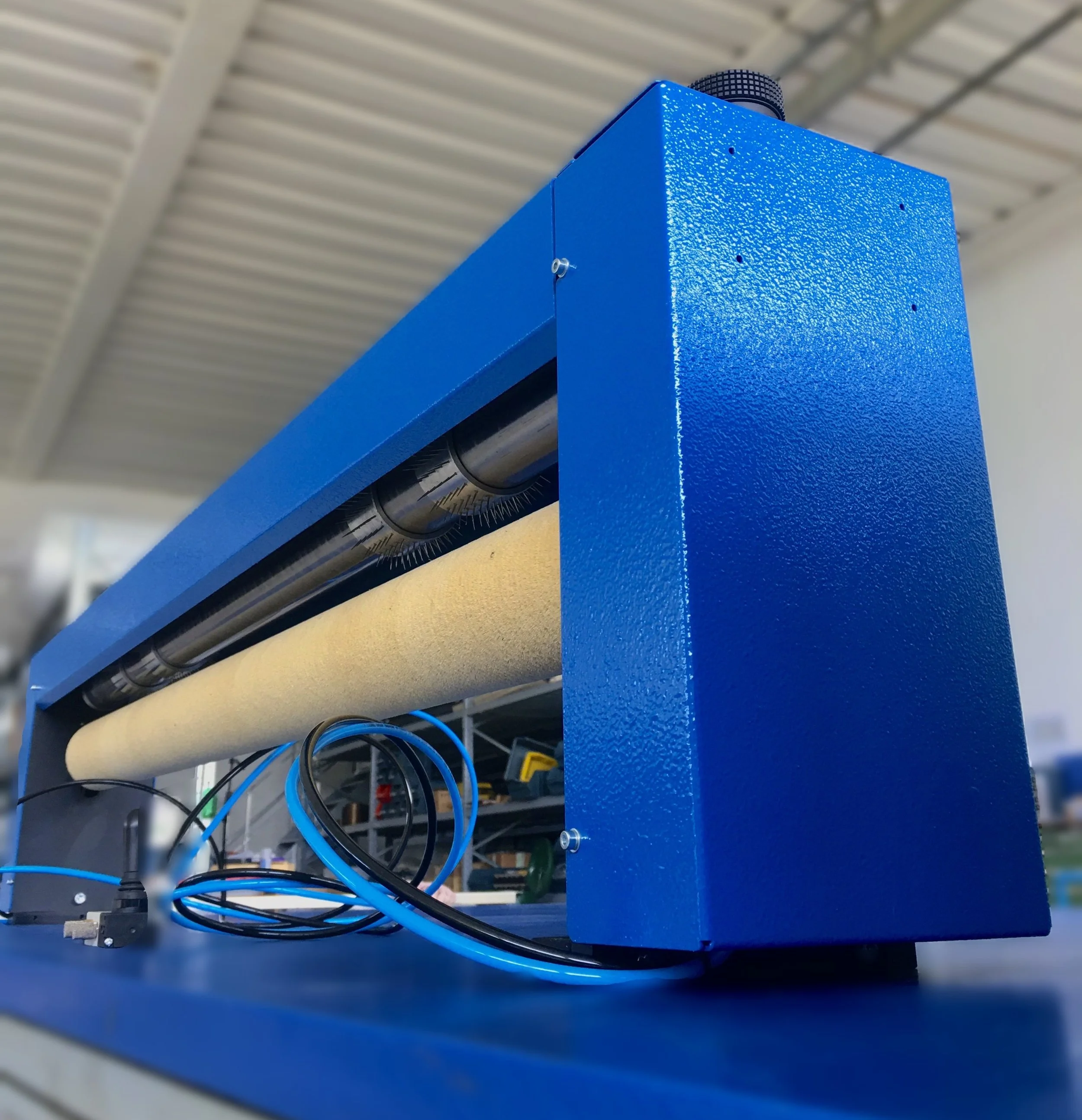

Model CN COLD MICRO PERFORATION system for holes from 80µ to 1mm with needle roller Ø 60mm - 100mm - 200mm

Description

The CN Series micro-hole perforators are compact, lightweight, and highly versatile solutions designed to create micro-holes of different diameters on moving film. Thanks to their reduced dimensions, they can be easily integrated into existing film-processing lines such as slitters, extruders, printing presses, welding machines, or any production line working with continuous film. They are ideal for producing micro-perforations in fresh produce bags, breathable and moisture-regulating packaging, thermal and acoustic insulation materials, electronic product packaging, and many other technical applications.

Operation

The system combines efficiency and precision: roller engagement is managed pneumatically, while penetration depth can be finely tuned with micrometric screws. Driven directly by the movement of the film, the CN Series automatically adapts to the speed of the host machine, ensuring perfect synchronization without the need for additional drives. This makes it a practical, reliable, and cost-effective solution for enhancing film functionality across a wide range of industries.

| TECHNICAL DATA SHEET | |

|---|---|

| Needle shaft Ø | 60mm - 100mm - 200mm |

| Hole Ø | Min. Ø80µ - Max. Ø1mm |

| Movement | Movement by film dragging |

| Penetration adjustment | Micrometric screws with graduated knobs |

| Maximum Speed | 400 mt minute* |

| Counter roller approach movement | Pneumatic movement |

| * | Value affected by material type and machine configuration |

For more detailed information click the link below

Model CN-EC COLD MICRO PERFORATION system for holes from 80µ to 1mm with needle roller Ø of 60mm - 100mm - 200mm

Description

System designed to make MICRO-HOLES on MOVING FILM of various materials and thicknesses and to be installed as a host unit in film transport lines, such as in slitters, extruders, printing and welding machines. The CNEC is ideal for those who must frequently vary production and regularly face changes in perforation patterns.

Operation

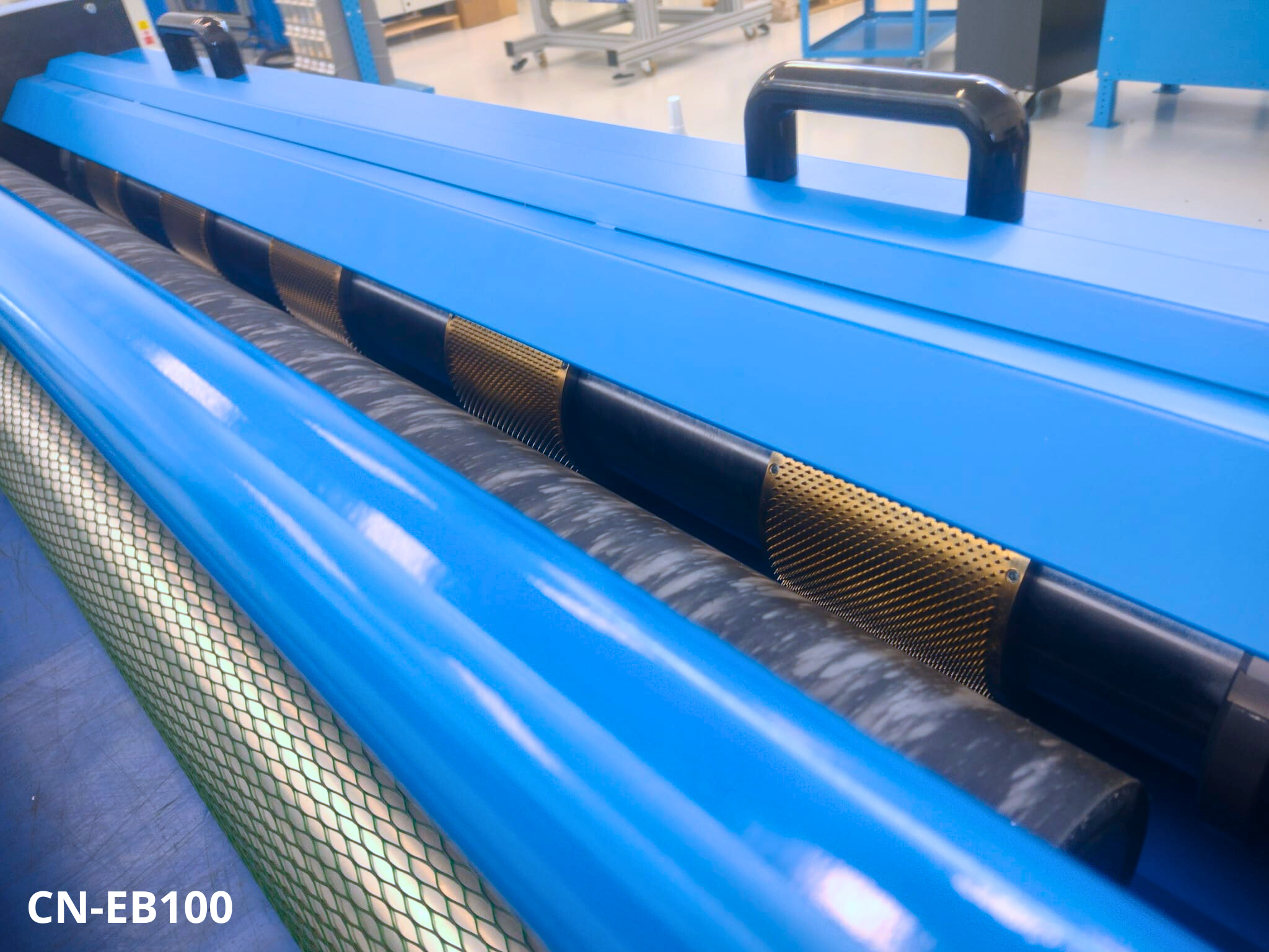

The running film enters the device and passes between the needle roller and the counter roller, which, as they engage, perforate the material. Roller contact is controlled pneumatically, while penetration depth is precisely adjusted using dual micrometric screws. To eliminate downtime and simplify job changes, the unit can be equipped with up to four rollers mounted on rotating plates, enabling rapid exchange of needle shafts through the Revolver System. Both shaft replacement and perforation adjustment can be performed with the machine either stopped or in motion, ensuring maximum flexibility and efficiency.

| TECHNICAL DATA SHEET | |

|---|---|

| Needle shaft Ø | 60mm - 100mm - 200mm |

| Hole Ø | Min. Ø80µ - Max. Ø1mm |

| Number of interchangeable shafts | Max. 4 per device |

| Equipment of needle shafts | Needle cylinders, embossing cylinders, fibrillators, longitudinal pre-cutting blades |

| Needle shaft changing system | Integrated manually operated revolver system |

| Movement of needle shafts | Movement by film dragging |

| Penetration adjustment | Micrometric screws with graduated knobs |

| Air Pressure | 6 BAR |

| Max Speed | 300* meters/minute |

| Contrast roller movement | Pneumatic |

| * | Value influenced by the type of processed material and machine configuration |

For more detailed information click the link below

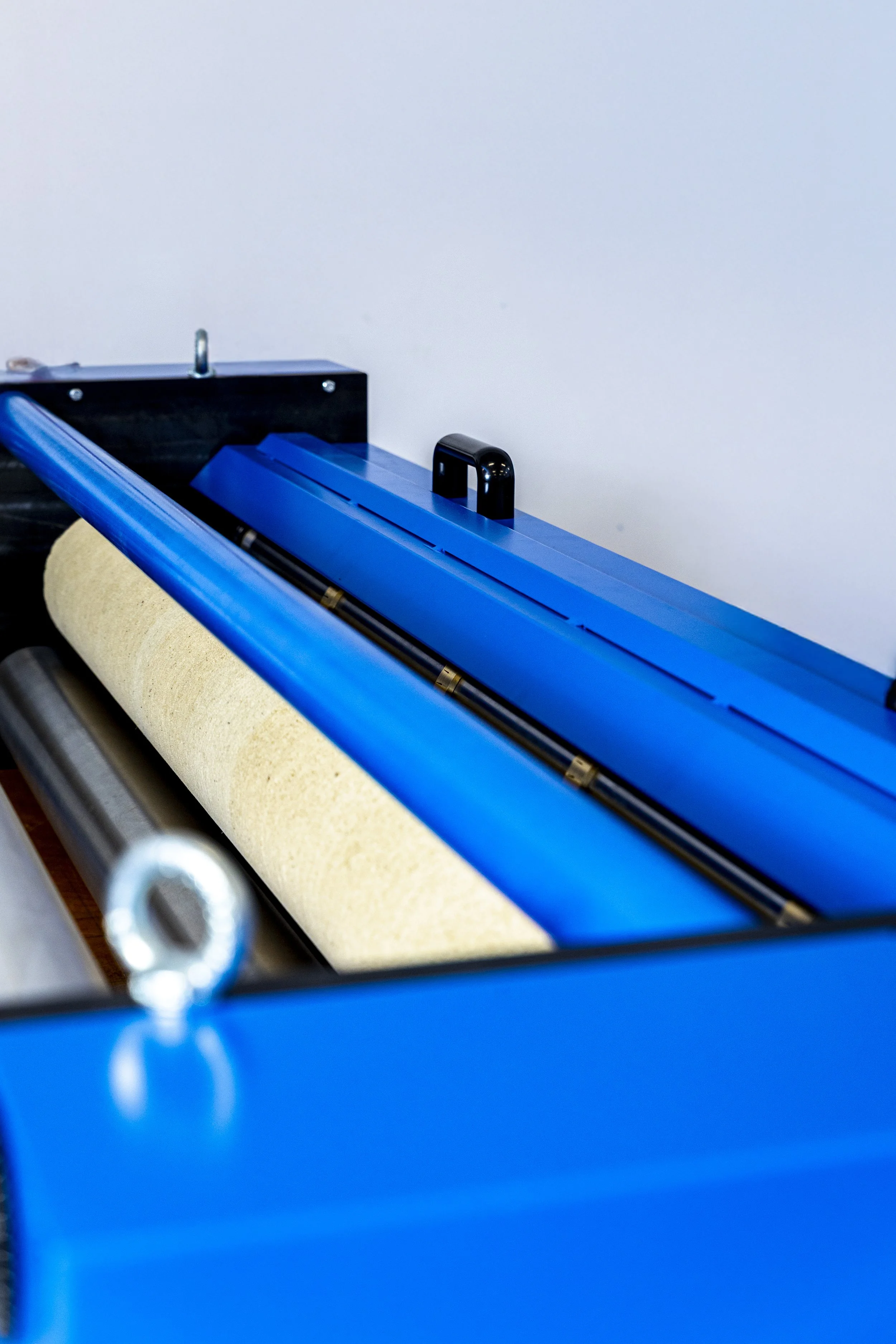

Model CN-MC COLD MICRO PERFORATION system for holes from 50µ to 1mm.

Description

The CNMC Micro Perforator is a compact and versatile solution designed to create micro-holes of different diameters on moving film with precision and efficiency. Thanks to its space-saving design, it can be seamlessly integrated into production lines such as slitters, extruders, printing and welding machines, or any system that processes continuous film.

A key advantage of the CNMC is its innovative needle roller change system. Rollers can be replaced while the machine is running, eliminating production stops: while one group operates, the other can be changed, and with a simple switch, the process continues seamlessly. This unique feature reduces downtime dramatically, boosting overall efficiency compared to conventional equipment.

Operation

The perforation process is handled by a dedicated unit with two needle roller groups and a central counter roller. As the film passes through one of the needle rollers and the counter roller, precise micro-holes are formed consistently and without interruption. Roller engagement is controlled pneumatically, while perforation depth can be finely adjusted with micrometric screws, ensuring maximum accuracy. Driven directly by film movement, the CNMC automatically adapts to the speed of the host machine, allowing continuous, perfectly synchronized operation.

| TECHNICAL DATA SHEET | |

|---|---|

| Needle shaft Ø | 100mm |

| Hole Ø | Min. Ø50µ - Max. Ø1mm |

| Movement | Movement by film dragging |

| Penetration adjustment | Micrometric screws with graduated knobs |

| Max Speed | 250* meters/minute |

| Counter roller approach movement | Pneumatic movement |

| Air Pressure | 6 BAR |

| * | Value influenced by the type of processed material and machine configuration |

For more detailed information click the link below

What is Cold Needle Perforation?

Cold needle perforation is a precision process that creates micro-holes in films and other materials using ultra-fine mechanical needles without the application of heat. Unlike hot needle perforation, which melts the material around each hole, cold perforation pierces it directly, preserving the substrate’s natural properties and avoiding thermal stress, discoloration, or shrinkage. Its use depends largely on the type of material: certain substrates, such as paper, laminates, or wood veneers, are better suited to cold perforation, as they cannot be effectively processed with heat. In addition to being more versatile, cold perforating is also more cost-effective, since it requires no heating system and consumes less energy, making it an economical choice for producing clean, burr-free holes and controlled permeability across a wide range of applications.

How Does Cold Needle Perforation Work?

Film Feeding: the moving web is guided and tensioned into the perforator by the host machine.

Roller Positioning: pneumatic actuators bring the needle roller into contact with the counter roller (rubber or brush-type), preparing the system for perforation.

Perforation: as the needle roller rotates, ultra-fine hardened needles pierce the substrate against the counter roller, creating clean, burr-free micro-holes without heat.

Adjustment & Synchronization: penetration depth is finely controlled with micrometric screws or motorized actuators. An encoder and asynchronous drive synchronize the perforator with the host line speed.

Advantages of Cold Needle Perforation

Cold needle perforation offers several key advantages that make it a preferred solution for many industries:

No heat application: prevents deformation, shrinkage, or discoloration, preserving the material’s natural properties.

Material versatility: suitable for plastics, laminates, technical films, paper, packaging substrates, and more.

One-way flow: enables controlled air or gas exchange while preventing leaks, ideal for breathable or protective packaging.

Cost-effective and fast: low energy consumption, high productivity, and minimal maintenance deliver excellent efficiency and reduced operating costs.

Why choose Spark Machinery?

Uncompromising Quality, Reliability & Performance

Spark Machinery designs and builds high-performance systems known for their precision, durability, and consistent output. Our machines operate reliably even under high-speed, high-demand production conditions, delivering top-tier results with minimal downtime.

Tailor-Made Solutions for Every Customer

We don’t believe in one-size-fits-all. Every system is engineered based on the specific needs of our customers—whether it’s material type, production speed, perforation pattern, or integration with existing lines. This ensures optimal efficiency and seamless operation from day one.End-to-End Support

Our commitment goes beyond machine delivery. We offer expert guidance during project planning, hands-on support during installation and training, and responsive service throughout the machine’s operational life. We're your partner before, during, and after purchase.Driven by Research & Innovation

At Spark Machinery, continuous improvement is part of our DNA. We invest heavily in R&D and testing to develop cutting-edge perforation technologies, improve system capabilities, and stay ahead of evolving market demands. Innovation is what keeps us competitive, and we deliver it with every machine.

Areas of application of our Cold Needle Perforator Machines

Food packaging: Used to release excess air in bulk packs of frozen goods or pet food, ensuring packaging stability and product quality.

Fresh-cut produce and bakery items: Helps excess moisture escape from the package, reducing condensation and extending shelf life.

Absorbent meat pad envelopes: Perforated poly films allow liquid to enter the absorbent pad while preventing it from leaking back out, keeping meat fresh and improving hygiene.

Residential construction: Applied in radiant barriers and house wraps to let moisture vapor pass through while blocking liquid. This allows humidity generated indoors to escape through the attic, preventing damage and maintaining building performance.

Weed control liners: Perforated barriers with micro-holes let air and water flow through the soil while stopping weed growth. They offer a safe, efficient alternative to chemical herbicides for both home gardening and agricultural use.

Acoustic management: Designed to let sound waves pass through a surface into an absorbing core, reducing noise and echo. This technique is widely used in vehicle interiors, heavy machinery, building panels, and wall boards, where hole size and density are tailored to control sound performance.

Get expert advice for your Micro Perforation Needs

Choosing the ideal micro-perforating machine can be a complex decision, given the diverse technologies and material considerations involved. To ensure you select the perfect solution for your specific needs, we invite you to a free, no-obligation consultation with our experts. Benefit from personalized insights into how the right hot, cold, or laser perforation technology can optimize your production, enhance product quality, and drive efficiency, ensuring a smart investment tailored to your success.

PERSONAL CONTACT

Looking for advanced industrial packaging or custom perforation solutions?

Discover how tailored airflow, moisture control, and material efficiency can elevate your logistics and product protection.

Contact our team today to explore custom-engineered perforation systems designed for your specific industry needs.

👉 Get in touch now or request a free consultation

FEDERICA CANTAGALLI

Commercial Export Office